Multifunctional nano building exterior wall coating and preparation method thereof

A multi-functional technology for building exterior walls, applied in antifouling/underwater coatings, coatings, and biocide-containing paints, etc., which can solve problems such as surface cracks, increased external pollution, and artificial high-altitude operations. , to achieve the effects of excellent mechanical properties, enhanced compounding ability, and good anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

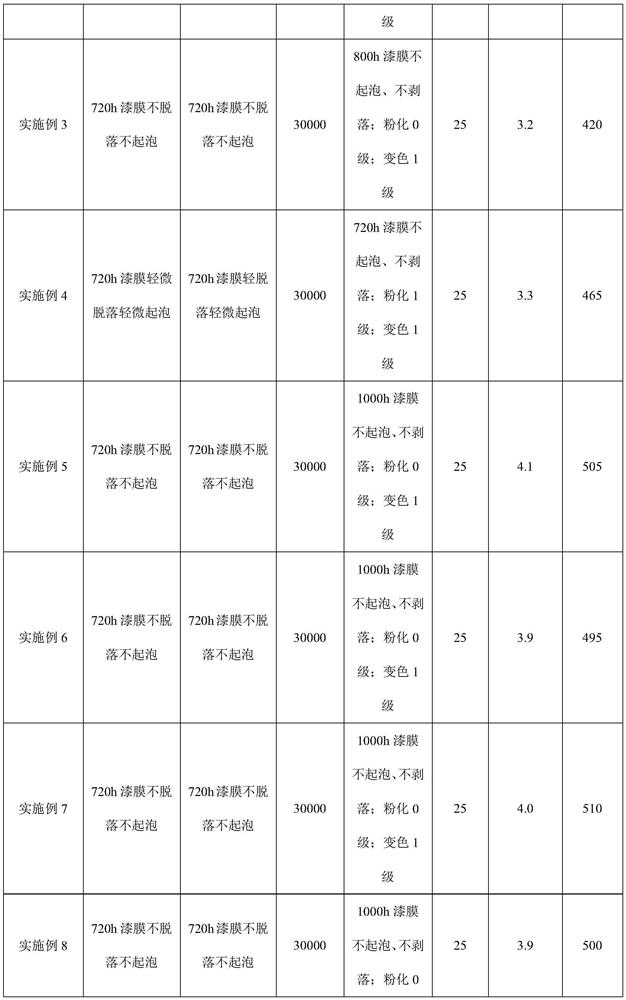

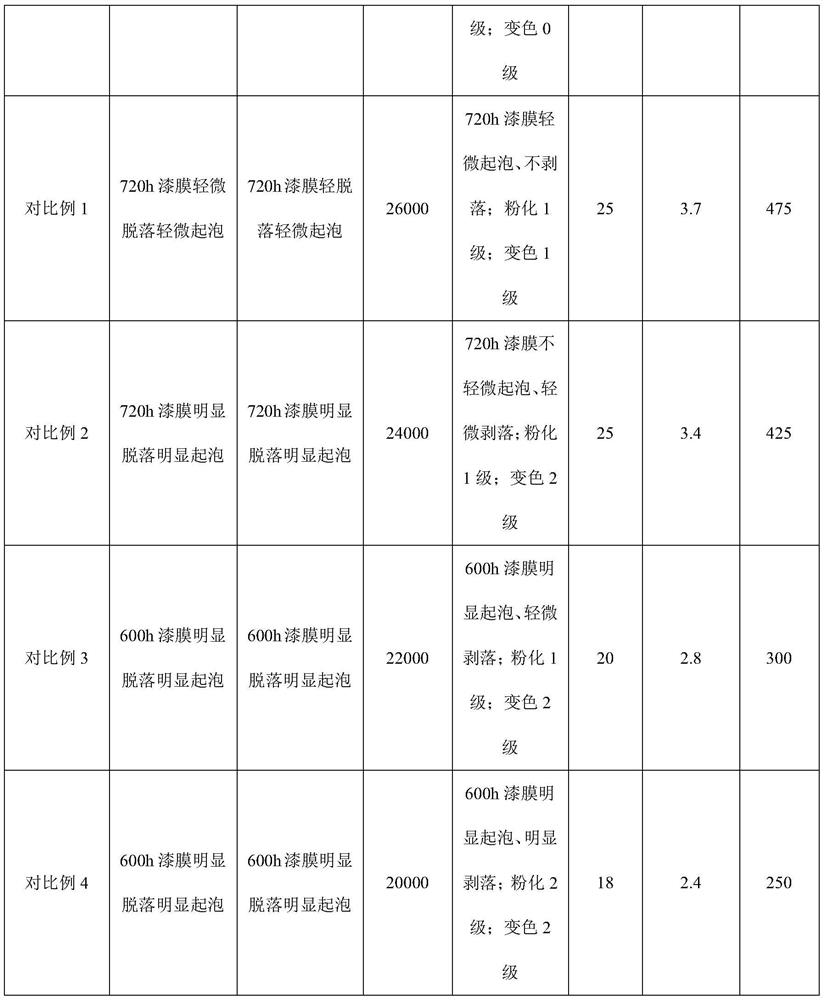

Examples

Embodiment 1

[0037] 1. Preparation of MoS2 / Nanocellulose Composites

[0038] (1) Processing I

[0039]Preparation of nanocellulose fibers: take a certain amount of fiber log pulp suspension, add 6.0 mol / L NaBr solution, 0.01 mol / L TEMPO solution and 6.0 mol / L NaClO solution in turn to form a mixed solution, and use 0.2 mol / L NaOH solution to mix it. The pH value of the above mixed solution is adjusted to 10-10.5. Subsequently, the above mixed solution was mechanically stirred for 1 hour and sonicated for 30 minutes, then an appropriate amount of methanol was added to terminate the reaction, then 0.1 mol / L HCl solution was added to adjust the pH value to 7, filtered and washed 2 to 3 times, and redispersed to obtain nanometers. Cellulose fiber dispersion;

[0040] Preparation of molybdenum disulfide: using ammonium paramolybdate ((NH 4 ) 6 Mo 7 O 24 ·6H 2 O) is molybdenum source, thiourea (CS(NH) 2 ) 2 ) is a sulfur source, dissolve 0.3g of ammonium paramolybdate and 0.6g of thiour...

Embodiment 2

[0067] The coating formula for preparing this example is: 40 parts of water-based elastic emulsion, 20 parts of water-based fluorocarbon emulsion, 12 parts of molybdenum disulfide / nanocellulose composite, 12 parts of nano-titanium dioxide, 20 parts of nano-filler, 2 parts of dispersant, and 2 parts of moisturizing agent. 0.8 part of wetting agent, 2 parts of film-forming aid, 0.5 part of defoamer, 0.2 part of PH regulator, 0.4 part of thickener, 0.3 part of preservative, and 15 parts of water; among them, molybdenum disulfide / nanocellulose composite The molybdenum disulfide / nanocellulose composite of treatment I in Example 1 was used, and the nano-titania was coated with the hydrated alumina of treatment IV in Example 1 to coat the modified nano-titania.

[0068] The method for preparing the coating of the present embodiment is as follows: stir the molybdenum disulfide / nanocellulose composite and nano-titanium dioxide for 30 to 40 minutes to fully mix, then add water-based elas...

Embodiment 3

[0070] The coating formulation for preparing this example is: 30 parts of water-based elastic emulsion, 30 parts of water-based fluorocarbon emulsion, 12 parts of molybdenum disulfide / nanocellulose composite, 12 parts of nano-titanium dioxide, 20 parts of nano-filler, 2 parts of dispersant, moisturizing agent 0.8 part of wetting agent, 2 parts of film-forming aid, 0.5 part of defoamer, 0.2 part of PH regulator, 0.4 part of thickener, 0.3 part of preservative, and 15 parts of water; among them, molybdenum disulfide / nanocellulose composite The molybdenum disulfide / nanocellulose composite of treatment I in Example 1 was used, and the nano-titania was coated with the modified nano-titania using the hydrated alumina of treatment IV in Example 1.

[0071] The method for preparing the coating of the present embodiment is as follows: stir the molybdenum disulfide / nanocellulose composite and nano-titanium dioxide for 30 to 40 minutes to fully mix, then add water-based elastic emulsion, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com