Preparation method of monodisperse polyesteramine microspheres

A polyester amine microsphere, monodisperse technology, applied in the direction of polymer adhesive additives, adhesive additives, etc., can solve the problem of poor compatibility of adhesive matrix, poor dispersion, affecting the performance of adhesives, etc. problems, to achieve the effect of simple operation, low production cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] At room temperature, in a 30 mL glass reaction flask, 18.8 g of acetonitrile was used as the reaction solvent, and 0.9678 g of monomer TMPTA and 0.2322 g of piperazine were added, and the addition amount accounted for 6wt% of the total mass of the system. The reaction flask was sealed and shaken to make each group The mixture was evenly mixed, and the reaction flask was placed in a refrigerator storage room at 4°C for 12 hours, and then taken out. The product was subjected to suction filtration, the obtained solid was washed three times with acetonitrile solution, and dried to constant weight in a forced air drying oven at 70° C. to obtain PEA microspheres.

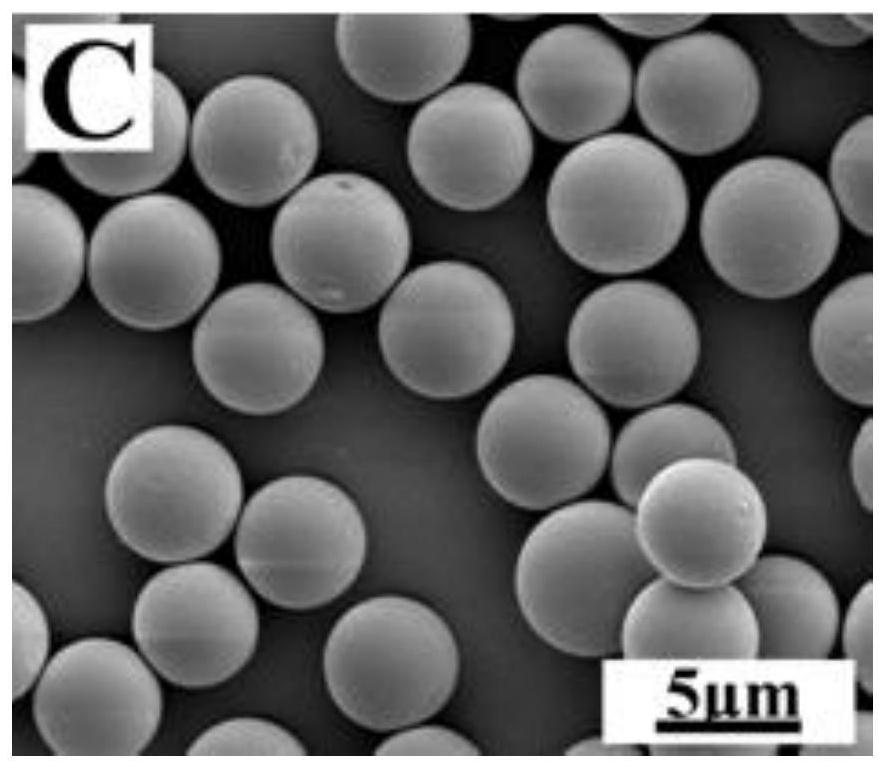

[0046] The yield of the obtained polyester-amine microspheres was 72.44%, and the scanning electron microscope photo of the microspheres is as follows: figure 1 As shown, the average particle size of the microspheres was thus measured to be 4.52 μm, and the particle size polydispersity coefficient was 1.011.

Embodiment 2

[0048] At room temperature, in a 30 mL glass reaction flask, 18.8 g of acetonitrile was used as the reaction solvent, 0.9398 g of TMPTA and 0.2602 g of piperazine were added, and the addition amount accounted for 6wt% of the total mass of the system, and the reaction flask was sealed and shaken to make each group The mixture was evenly mixed, and the reaction flask was placed in a refrigerator storage room at 4°C for 12 hours, and then taken out. The product was subjected to suction filtration, the obtained solid was washed three times with acetonitrile solution, and dried to constant weight in a forced air drying oven at 70° C. to obtain PEA microspheres.

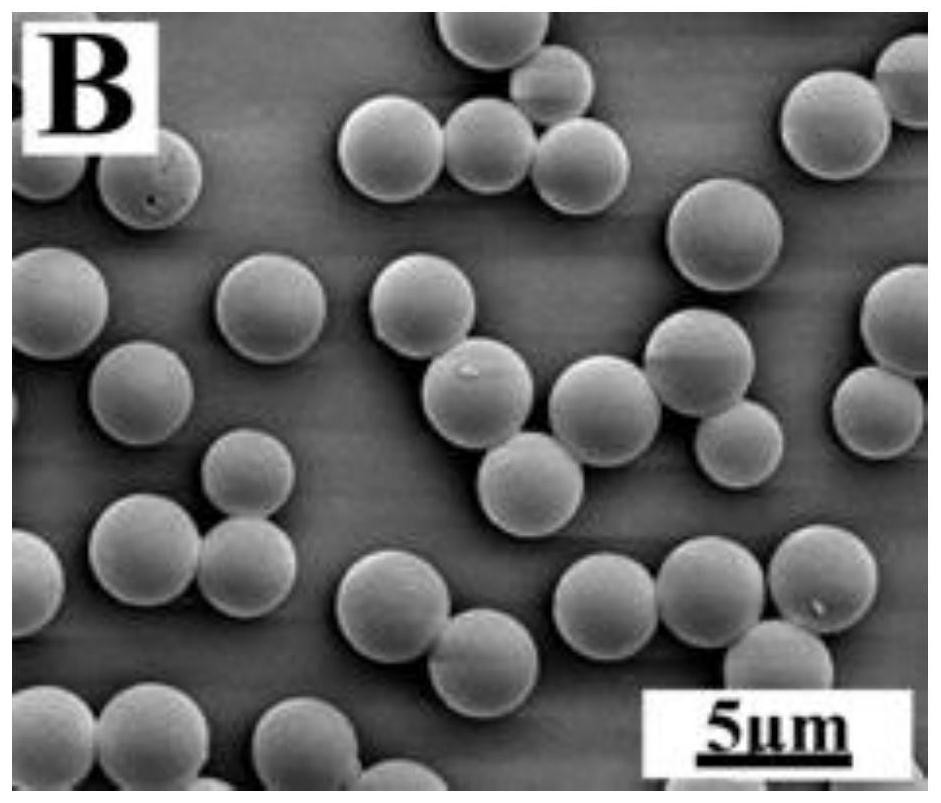

[0049] The yield of the obtained polyester-amine microspheres was 69.88%, the average particle diameter of the microspheres was 4.01 μm, and the particle diameter polydispersity coefficient was 1.025.

Embodiment 3

[0051] At room temperature, in a 30 mL glass reaction flask, 18.8 g of acetonitrile was used as the reaction solvent, and 0.9678 g of monomer TMPTA and 0.2322 g of piperazine were added, and the addition amount accounted for 6wt% of the total mass of the system. The reaction flask was sealed and shaken to make each group The mixture was evenly divided, and the reaction flask was placed in a refrigerator storage room at 30° C. for 12 hours to stand for reaction, and then taken out. The product was subjected to suction filtration, the obtained solid was washed three times with acetonitrile solution, and dried to constant weight in a forced air drying oven at 70° C. to obtain PEA microspheres.

[0052] The yield of the obtained polyester-amine microspheres was 67.43%, the average particle size of the microspheres was 3.47 μm, and the particle size polydispersity coefficient was 1.046.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com