Low-dielectric high-thermal-conductivity composite film and preparation method thereof

A composite thin film, high thermal conductivity technology, applied in the direction of climate change adaptation, etc., can solve the problems of easy electric shock, heat increase, easy conduction, etc., to reduce the possibility of leakage, improve dispersion, and reduce inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

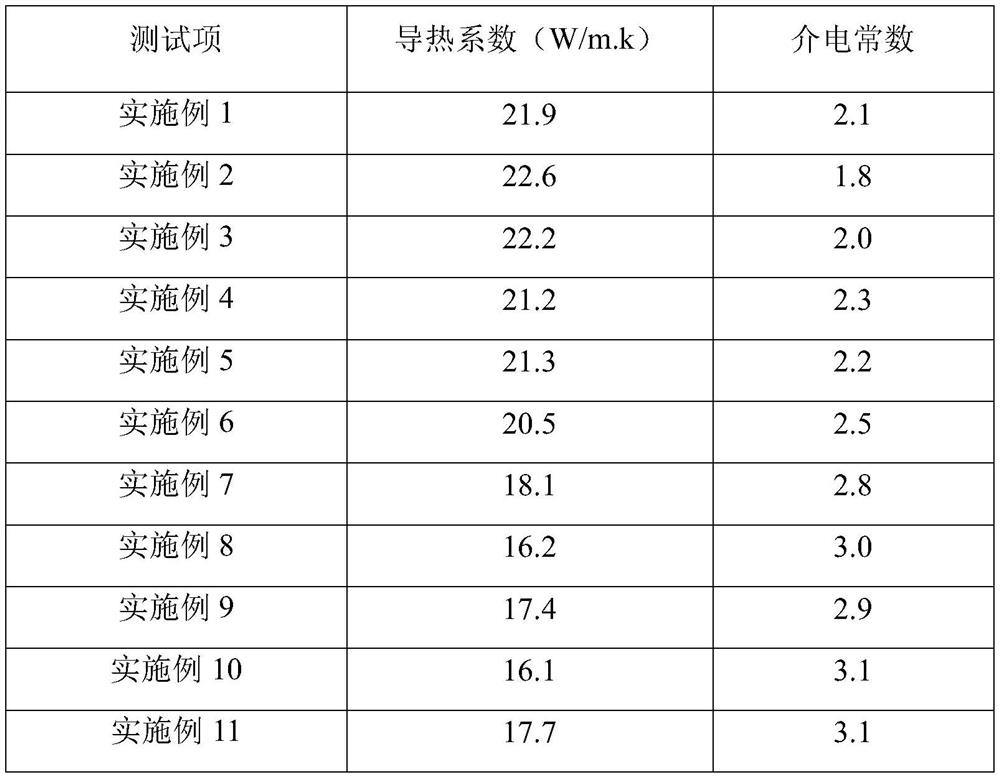

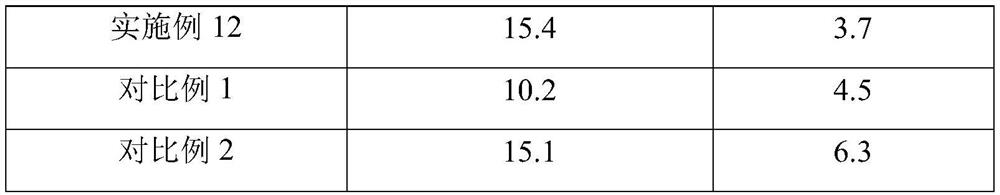

Examples

preparation example 1

[0049] A modified boron nitride, comprising the following preparation steps:

[0050] Step 1: Weigh 0.2Kg of sodium pyrophosphate, 5Kg of sodium hydroxide and 1Kg of potassium hydroxide, dissolve them in 100Kg of water, heat to 55°C, add 20Kg of boron nitride while stirring, stir for 3 hours, filter with a suction filter pump, and The filter residue is placed in an oven for drying for 8 hours to obtain pretreated boron nitride;

[0051] Step 2: Weigh 0.3Kg of fatty alcohol polyoxyethylene ether, 30Kg of alcohol solution with a mass fraction of 55% and 5Kg of 4-methyl-2-pentanol, add all the pretreated boron nitride obtained in step 1, and put into ultrasonic Vibrate for 2Kgh, the frequency of ultrasonic waves is 40KHZ, filter with a suction filter pump, put the filter residue in an oven for drying for 6h, and obtain modified boron nitride.

preparation example 2

[0053] A modified boron nitride, comprising the following preparation steps:

[0054] Step 1: Weigh 0.3Kg of sodium pyrophosphate, 6Kg of sodium hydroxide and 2Kg of potassium hydroxide, dissolve them in 100Kg of water, heat to 65°C, add 25Kg of boron nitride while stirring, stir for 4h, filter with a suction filter pump, The filter residue is placed in an oven for drying for 8 hours to obtain pretreated boron nitride;

[0055] Step 2: Weigh 0.5Kg of fatty alcohol polyoxyethylene ether, 40Kg of alcohol solution with a mass fraction of 65% and 7Kg of 4-methyl-2-pentanol, add all the pretreated boron nitride obtained in step 1, and put it into ultrasonic Vibrate for 2.5h, the frequency of ultrasonic waves is 40KHZ, filter with suction filter pump, put the filter residue in an oven for drying for 6h, and obtain modified boron nitride.

preparation example 3

[0057] A modified boron nitride, comprising the following preparation steps:

[0058] Step 1: Weigh 0.3Kg of sodium pyrophosphate, 8Kg of sodium hydroxide and 3Kg of potassium hydroxide and dissolve them in 100Kg of water, heat to 75°C, add 30Kg of boron nitride while stirring, stir for 5h, filter with a suction filter pump, The filter residue is placed in an oven for drying for 6 hours to obtain pretreated boron nitride;

[0059] Step 2: Weigh 0.8Kg of fatty alcohol polyoxyethylene ether, 50Kg of alcohol solution with a mass fraction of 75% and 10Kg of 4-methyl-2-pentanol, add all the pretreated boron nitride obtained in step 1, and put it into ultrasonic Vibrate for 3 hours, the frequency of the ultrasonic wave is 40KHZ, filter with a suction filter pump, put the filter residue in an oven for drying for 6 hours, and obtain modified boron nitride.

[0060] Comparative Example of Preparation of Modified Boron Nitride

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com