Automatic powder spraying device of glass lining equipment

A glass-lined and powder-spraying technology, which is applied in the field of automatic powder-spraying devices, can solve problems such as inability to spray powder on tanks of different sizes, uneven powder spraying, and increased production costs, and achieve flexible use, good spraying effects, and streamlined production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

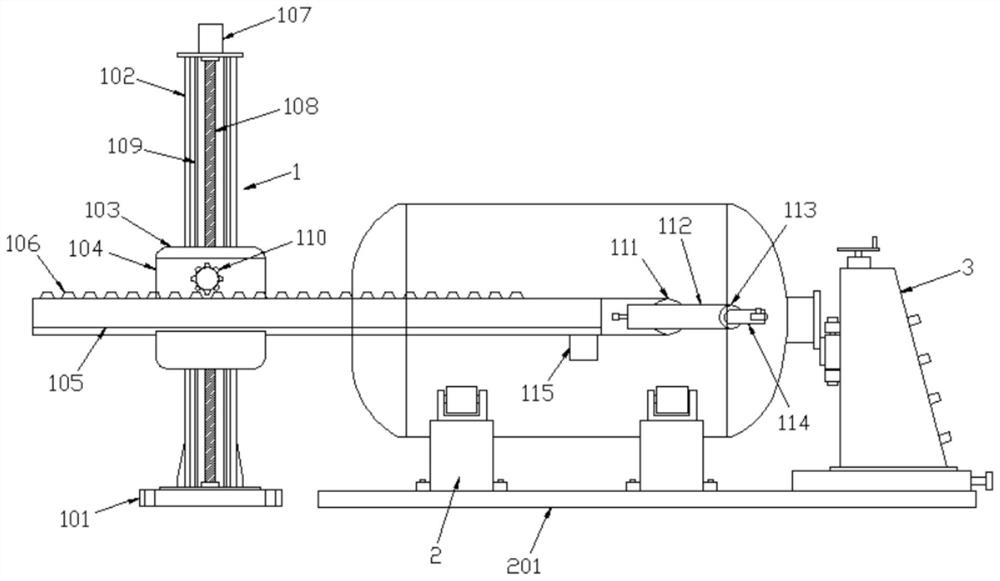

[0023] Example 1: see figure 1 , the present invention provides a technical solution: an automatic powder spraying device for glass-lined equipment, comprising a powder spraying support mechanism 1, a tank body support mechanism 2 and a tank body anti-channeling mechanism 3; the powder spraying support mechanism 1 includes a first The base 101, the top of the first base 101 is fixed with a vertical rod 102, the external sliding sleeve of the vertical rod 102 is provided with a lifting block 103, and the lifting block 103 is driven by a lifting mechanism; The front side is provided with a first chute 104, the first chute 104 is provided with a boom telescopic shaft 105, and the bottom end of the boom telescopic shaft 105 is slidably connected to the inner bottom wall of the first chute 104. A rack 106 is provided on the top of the boom telescopic shaft 105, and the rack 106 is driven by a gear mechanism.

[0024] In this embodiment, the lifting mechanism includes a lifting mot...

Embodiment 2

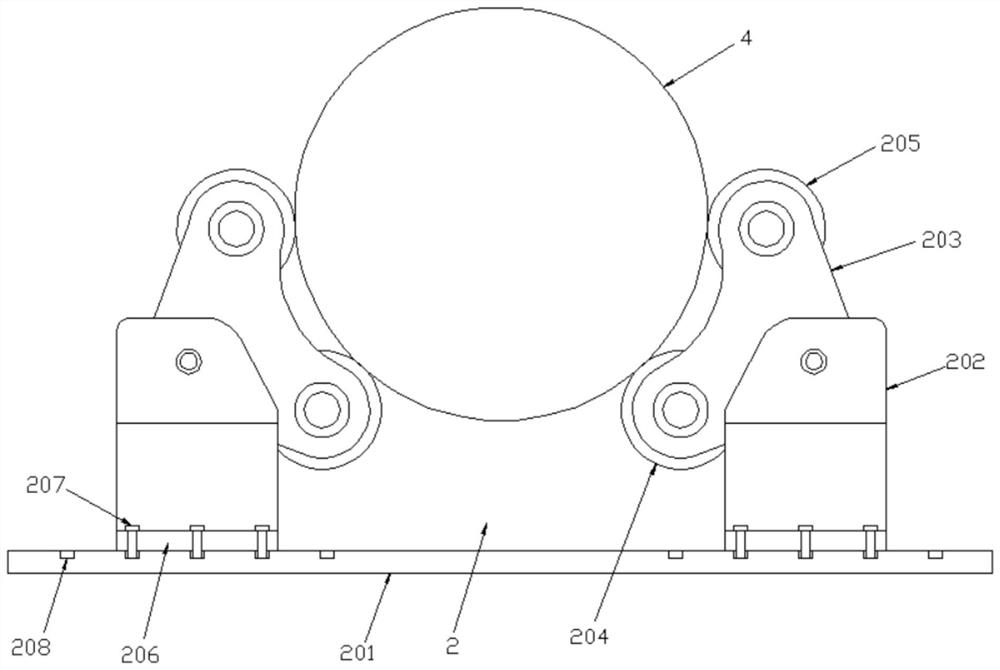

[0029] Example 2: see figure 2 , the tank body support mechanism 2 is used to support the tank body 4, the tank body support mechanism 2 includes a second base 201, and the top of the second base 201 is provided with four moving seats 202 in a rectangular array, so An enclosing frame 203 is installed on the movable seat 202 , a numerical control driving wheel 204 is installed at the bottom of the surrounding frame 203 , and a guide wheel 205 is installed at the top of the surrounding frame 203 ; the bottoms of both sides of the movable seat 202 are fixedly connected There is a fixing plate 206 on which a tightening bolt 207 is movably arranged, and the head end of the tightening bolt 207 is threadedly connected with a reserved hole 208 opened on the upper surface of the second base 201, and the reserved hole 208 is provided There are several, several reserved holes 208 are divided into 8 groups, and each group is arranged in a linear array.

[0030]The movable seat 202 is fi...

Embodiment 3

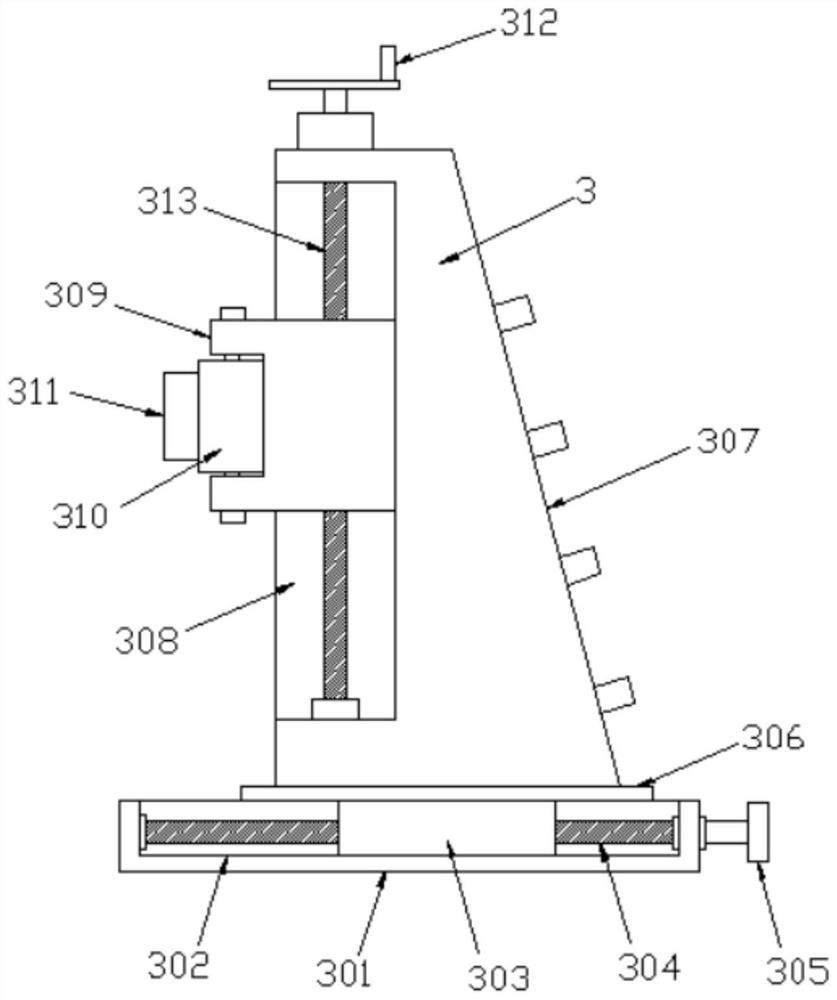

[0031] Example 3: see image 3 , the tank anti-channeling mechanism 3 includes a third base 301, the third base 301 is fixed on the top of the second base 201, the top of the third base 301 is provided with a moving groove 302, and the moving groove 302 A moving block 303 is slidably connected inside, and a second screw rod 304 is screwed through the moving block 303. One end of the second screw rod 304 is rotatably connected with the inner wall of the moving groove 302, and the other end is movable through the moving groove 302 and fixed. The first hand wheel 305 is connected; the top of the moving block 303 is fixed with a moving plate 306, the bottom of the moving plate 306 is slidably connected with the top of the third base 301, and the top of the moving plate 306 is fixed with a base 307, The side of the base 307 facing the tank body support mechanism 2 is provided with a second chute 308 , and a mounting block 309 is slidably connected in the second chute 308 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com