Activated carbon-removed low-color diisobutyl phthalate production device and production method thereof

A technology for producing diisobutyl phthalate and a production device is applied in the field of deactivated carbon and low color diisobutyl phthalate production devices, and can solve the problems of reducing production cost, increasing the amount of solid waste, and high production cost , to achieve the effect of reducing side reactions, reducing color, and reducing the production of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

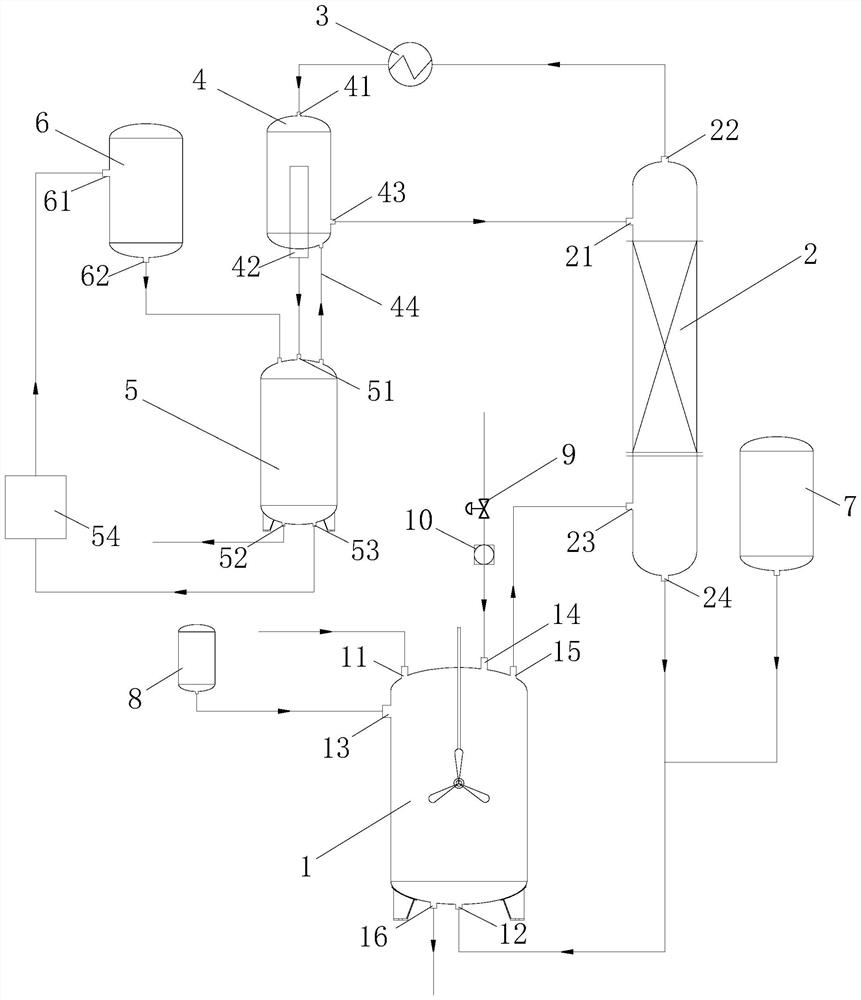

[0027] like figure 1 As shown, the present embodiment provides a deactivated carbon low-color diisobutyl phthalate production device, comprising an esterification kettle 1 with a temperature control device, an esterification tower 2, a separation Phase device 4, alcohol-water separator 5 and recovery alcohol tank 6;

[0028] The esterification kettle is provided with a first inlet 11, a second inlet 12, a catalyst inlet 13, a nitrogen inlet 14, a first outlet 15 and a second outlet 16;

[0029] The esterification tower is provided with a third feed port 21, a third discharge port 22, a fourth feed port 23 and a fourth discharge port 24, and the fourth feed port of the esterification tower and the esterification kettle No. A discharge port is connected with a pipeline, and the fourth discharge port of the esterification tower is connected with a pipeline of the second feed port of the esterification kettle;

[0030] The phase separator is provided with a fifth feed port 41, a...

Embodiment 2

[0040] like figure 1 As shown, the present embodiment provides a deactivated carbon low-color diisobutyl phthalate production device, including an esterification kettle 1 with a temperature control device, an esterification tower 2, a condensation 3, phase separator 4, alcohol-water separator 5, recovery alcohol tank 6, raw material alcohol tank 7 and catalyst tank 8;

[0041] The esterification kettle is provided with a first feeding port 11, a second feeding port 12, a catalyst inlet 13, a nitrogen inlet 14, a first discharging port 15 and a second discharging port 16; the nitrogen inlet of the esterification kettle The front is also provided with a pressure regulating valve 9 and a gas flow meter 10; the raw material alcohol tank is connected with the second feed port of the esterification kettle, and the catalyst tank is connected with the catalyst inlet pipeline of the esterification kettle;

[0042] The esterification tower is provided with a third feed port 21, a third...

Embodiment 3

[0052] like figure 1 As shown, the present embodiment provides a deactivated carbon low-color diisobutyl phthalate production device, including an esterification kettle 1 with a temperature control device, an esterification tower 2, a condensation 3, phase separator 4, alcohol-water separator 5, recovery alcohol tank 6, raw material alcohol tank 7 and catalyst tank 8;

[0053] The esterification kettle is provided with a first feeding port 11, a second feeding port 12, a catalyst inlet 13, a nitrogen inlet 14, a first discharging port 15 and a second discharging port 16; the nitrogen inlet of the esterification kettle The front is also provided with a pressure regulating valve 9 and a gas flow meter 10; the raw material alcohol tank is connected with the second feed port of the esterification kettle, and the catalyst tank is connected with the catalyst inlet pipeline of the esterification kettle;

[0054] The esterification tower is provided with a third feed port 21, a third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com