Nitrogen-oxygen-doped carbon nanohorn and preparation method and application thereof

A carbon nano-horn and nitrogen-oxygen technology, which is applied in the application field of nitrogen-oxygen-doped carbon nano-horn and nitrogen-oxygen-doped carbon nano-horn, can solve the problems of low recycling rate of thermally cracked carbon black, environmental pollution, waste of resources and the like , to achieve the effect of easy operation, reducing environmental pollution and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

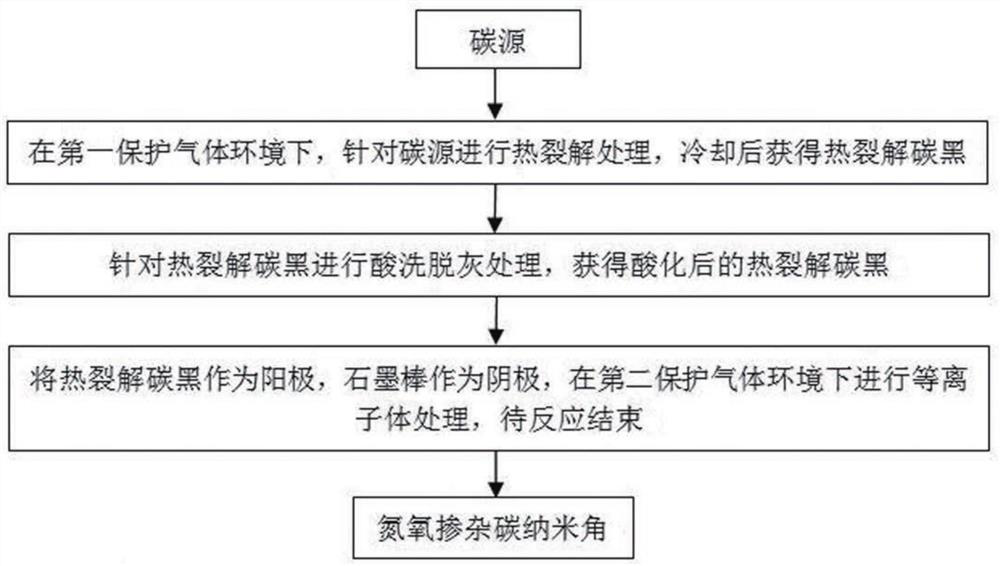

[0039]In an exemplary embodiment of the method for preparing nitroxide-doped carbon nanohorns of the present invention, the method for preparing nitroxide-doped carbon nanohorns may include the following steps:

[0040] (1) In the first protective gas environment, thermal cracking treatment is performed on the carbon source, and thermal cracking carbon black is obtained after cooling. The carbon source is waste tire powder.

[0041] It should be noted that the first protective gas may be at least one of nitrogen gas and argon gas. The purpose of setting the first protective gas is to prevent the sample from being oxidized by air.

[0042] The thermal cracking treatment can be performed by placing the carbon source in a heating device, such as a heating tube, and then heating it to a certain temperature under a protective gas, and keeping it for a period of time. black. Among them, the temperature-raising method can adopt the temperature-programmed method.

[0043] In the t...

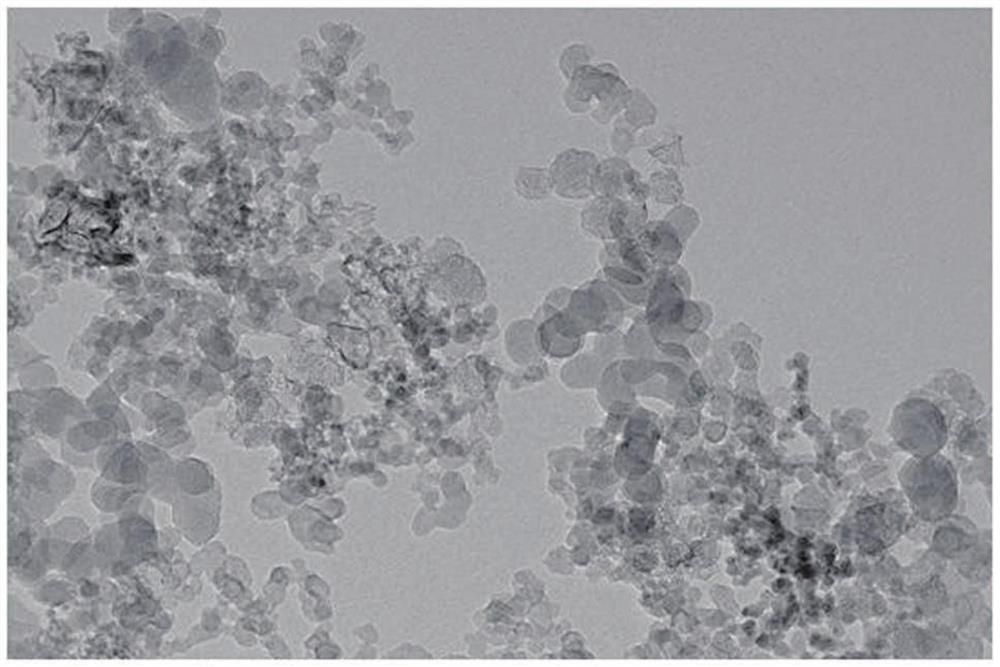

example 1

[0072] This example provides a method for preparing nitrogen-oxygen-doped carbon nanohorns by using waste tire powder, which is achieved through the following steps.

[0073] Step 1), put the waste tire powder in a quartz boat, spread it evenly, and transfer it to the heating tube of the device. Under nitrogen protection, the temperature was raised to 200°C at a heating rate of 2°C / min, and kept for 1 h, and then heated to 400°C at the same heating rate and kept for 1 h. After the reaction was completed, it was cooled to room temperature under a nitrogen atmosphere, and the sample was taken out to obtain thermal cracked carbon black. Nitrogen is the reactive gas required for the preparation of carbon nanohorns by the DC arc method.

[0074] Step 2), weigh 10 g of the thermally cracked carbon black obtained in step 1) and place it in a beaker, add 20 mL of nitric acid, acidify it in an oil bath at 60°C for 2 hours, and then wait for the sample to cool to room temperature and t...

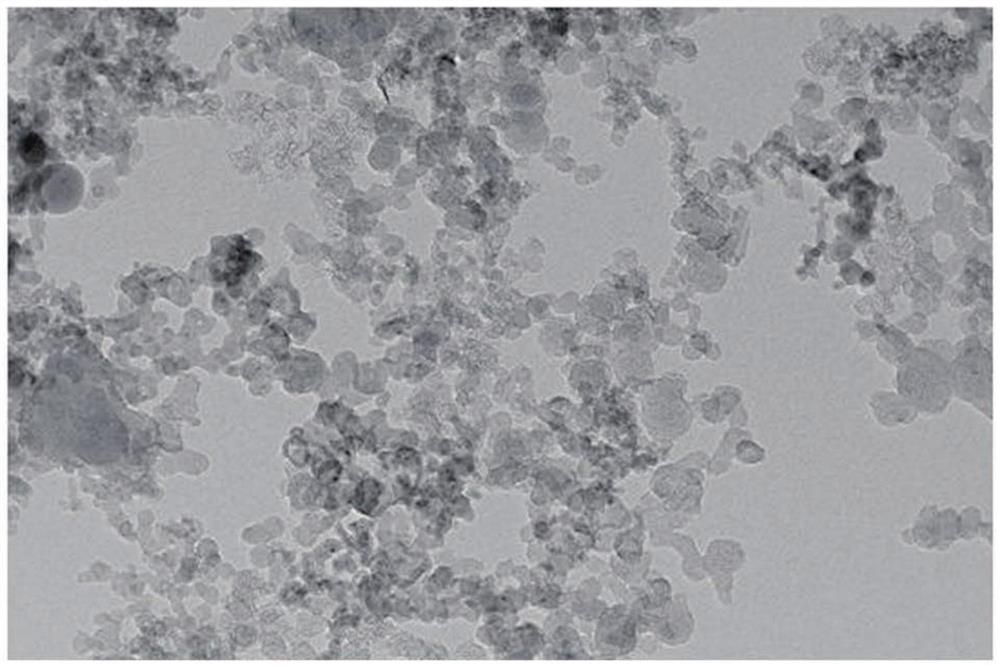

example 2

[0079] This example provides a method for preparing nitrogen-oxygen-doped carbon nanohorns by using waste tire powder, which is achieved through the following steps.

[0080] Step 1), put the waste tire powder in a quartz boat, spread it evenly, and transfer it to the heating tube of the device. Under nitrogen protection, the temperature was raised to 200°C at a heating rate of 2°C / min, and kept for 1 h, and then heated to 400°C at the same heating rate and kept for 2 h. After the reaction was completed, it was cooled to room temperature under a nitrogen atmosphere, and the sample was taken out to obtain thermal cracked carbon black.

[0081] In step 2), weigh 10 g of the thermally cracked carbon black obtained in step 1) and place it in a beaker, add 20 mL of nitric acid, acidify it in an oil bath at 80°C for 2 hours, then take out the sample after cooling to room temperature, add a large amount of nitric acid Soak in ionized water and wash with deionized water until the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com