Open type air source heat pump drying unit performance testing device and testing method thereof

An air source heat pump and drying unit technology, which is applied in the direction of measuring devices, testing of machine/structural components, and thermal development of materials, etc., can solve problems such as high return air temperature, fire in inspection and testing equipment, and damage to the health of inspection and testing personnel. The effect of improving experimental efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

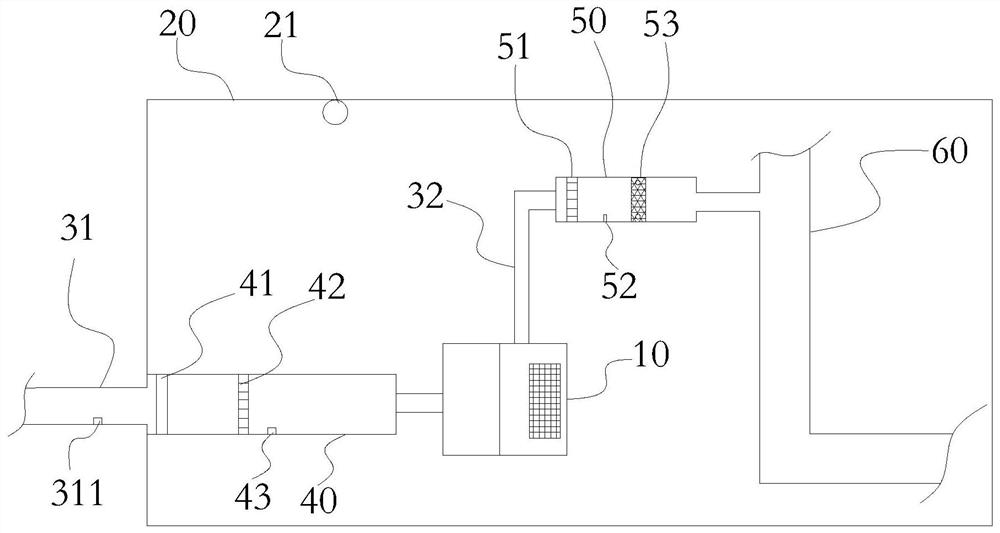

[0045] like figure 1 The shown device for testing the performance of an open air source heat pump drying unit is characterized in that it includes a drying unit 10 to be tested installed in the enthalpy difference laboratory 20 . The air inlet of the drying unit 10 to be tested is communicated with the ventilation pipe 31 outside the enthalpy difference laboratory 20 through the air inlet heating assembly; the air outlet of the drying unit 10 to be tested is connected to the wind tunnel 60 in the enthalpy difference laboratory 20 through the air outlet cooling assembly connected, and an induced draft fan is installed in the wind tunnel 60 . When the induced draft fan installed in the wind tunnel 60 is turned on, the air flow enters the air inlet heating assembly along the ventilation pipe 31, and the air inlet heating assembly heats the temperature of the air flow to the temperature of the experimental temperature field required for the performance test of the drying unit 10 t...

Embodiment 2

[0056] The specific operation steps of a performance testing method for an open air source heat pump drying unit are as follows:

[0057] S1: Install the drying unit 10 to be tested in the enthalpy difference laboratory 20, the air inlet of the drying unit 10 to be tested is connected with the heating equalizing box 40, the air outlet is connected to the heat insulating air duct 32, and the drying unit 10 to be tested is connected electrical connection with a computer;

[0058] S2: Set the standard values of the parameters to be measured for the drying unit 10 to be measured on the computer, and at the same time, the computer activates the induced draft fan in the wind tunnel 60 and the drying unit 10 to be tested;

[0059] The computer compares and analyzes the data tested by the first temperature sensor 311 and the second temperature sensor 43 with the standard value, and then adjusts the electric heating net 41 to heat the air in the heating equalizing box 40, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com