Method and device for evaluating reliability of industrial robot control system

A technology of industrial robots and control systems, which is applied in the field of robots and can solve problems such as poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

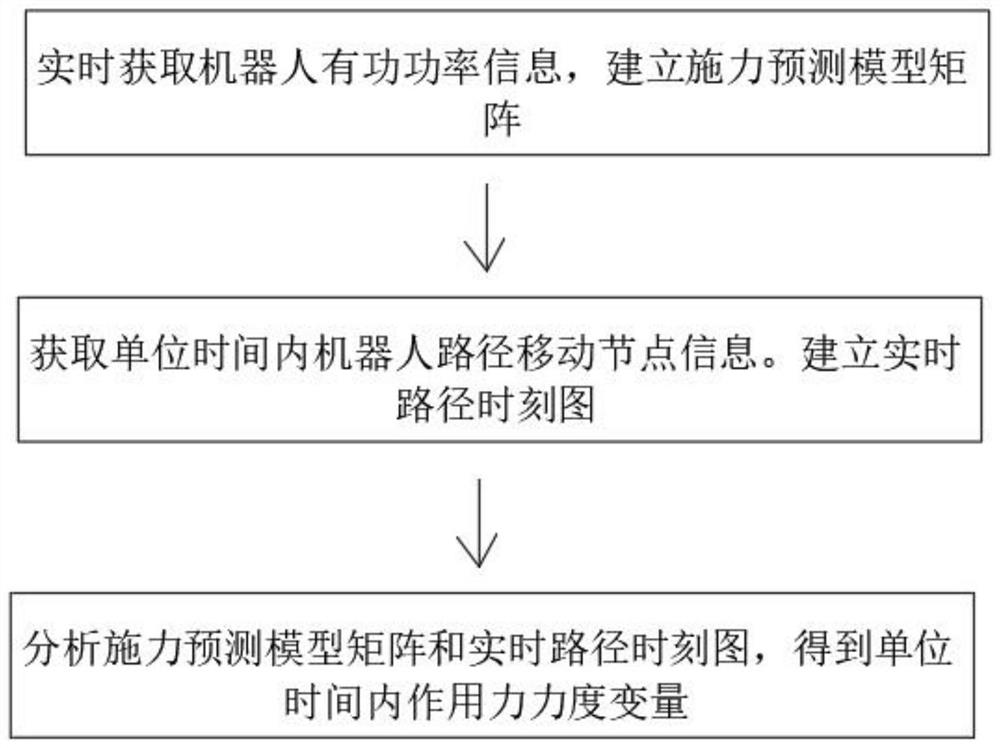

[0047] Example: A method for evaluating the reliability of an industrial robot control system. First, it is necessary to obtain the real-time active power information of the robot in a moving state per unit time, obtain the information on the force change of the robot during the movement of the robot per unit time through the power information, and establish a robot force prediction model matrix. , taking the common manipulator operation in industrial robots as an example of the evaluation object of this method:

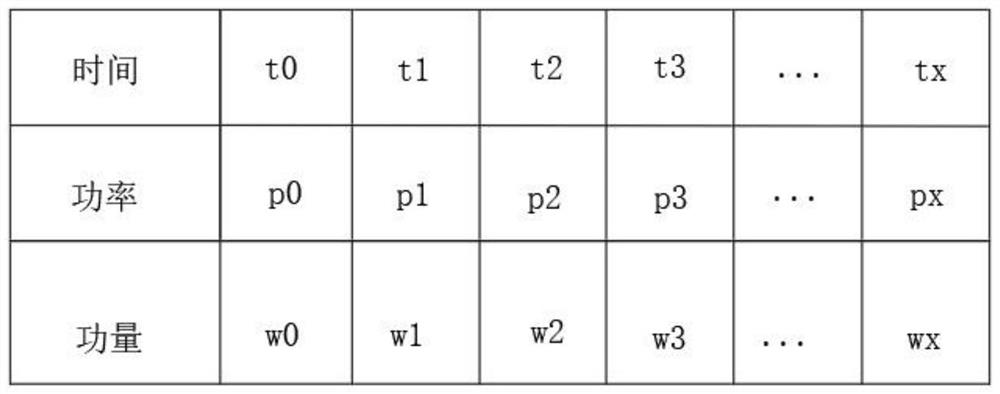

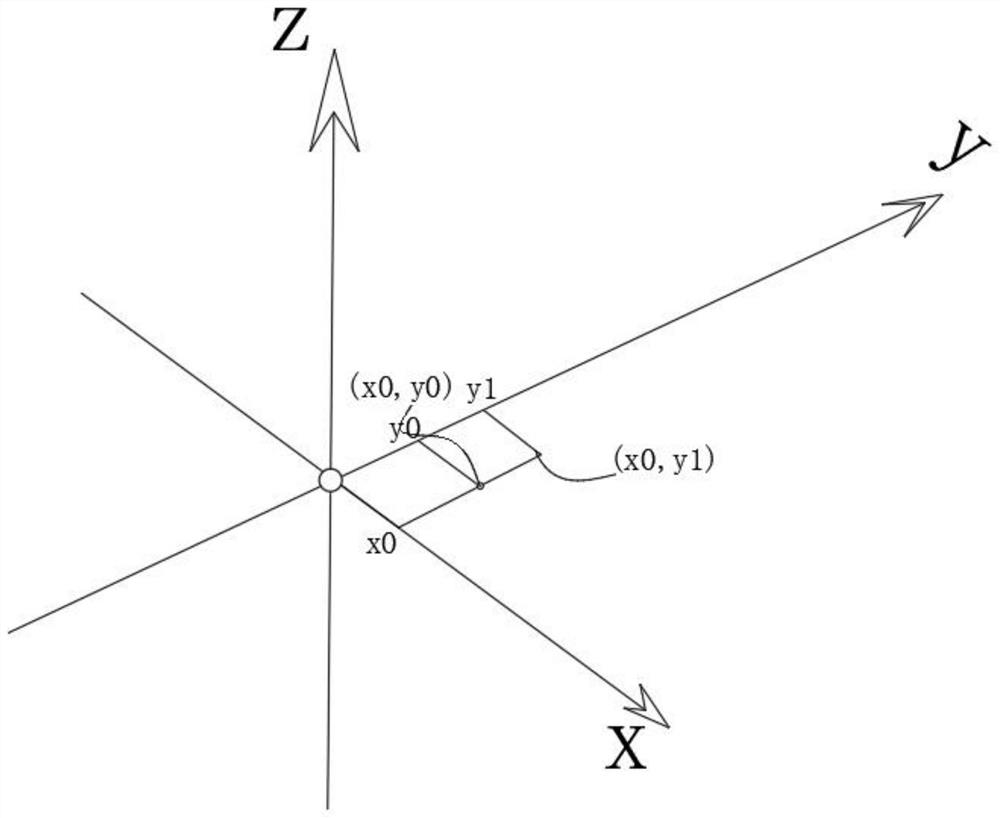

[0048] In the detection process, a three-dimensional coordinate system is first established in the detection environment of the robot, in which a distance sensor or a position sensor is used to determine whether the robot arm has reached the detection point, and the working time between the arriving nodes is divided into several times. point, record the time it takes for the manipulator to actually reach the time point, and record it as t 0 , t 1 , t 2 ...t x (t>0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com