Method and system for evaluating vibration of main shaft

An evaluation method and spindle technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of inconsistency in judgment errors, selection of spindles, and cumbersome detection process, etc., to improve consistency and stability Sexuality, avoiding waste of resources, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

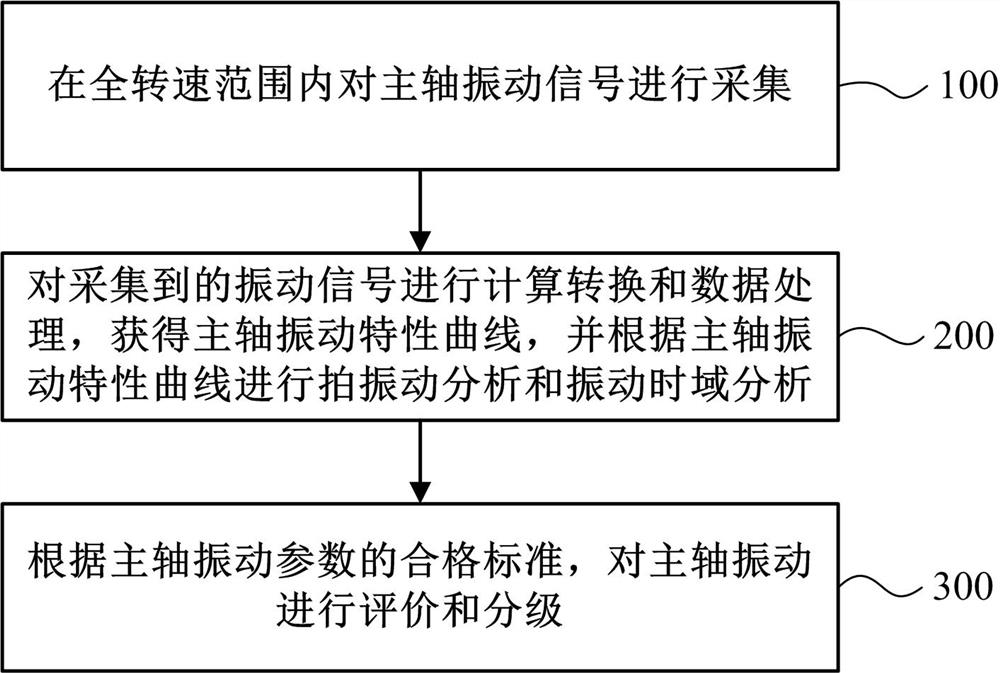

[0044] like figure 1 As shown, a method for evaluating the vibration of a main shaft of the present invention includes:

[0045] Step 100, collecting the vibration signal of the main shaft within the full rotational speed range;

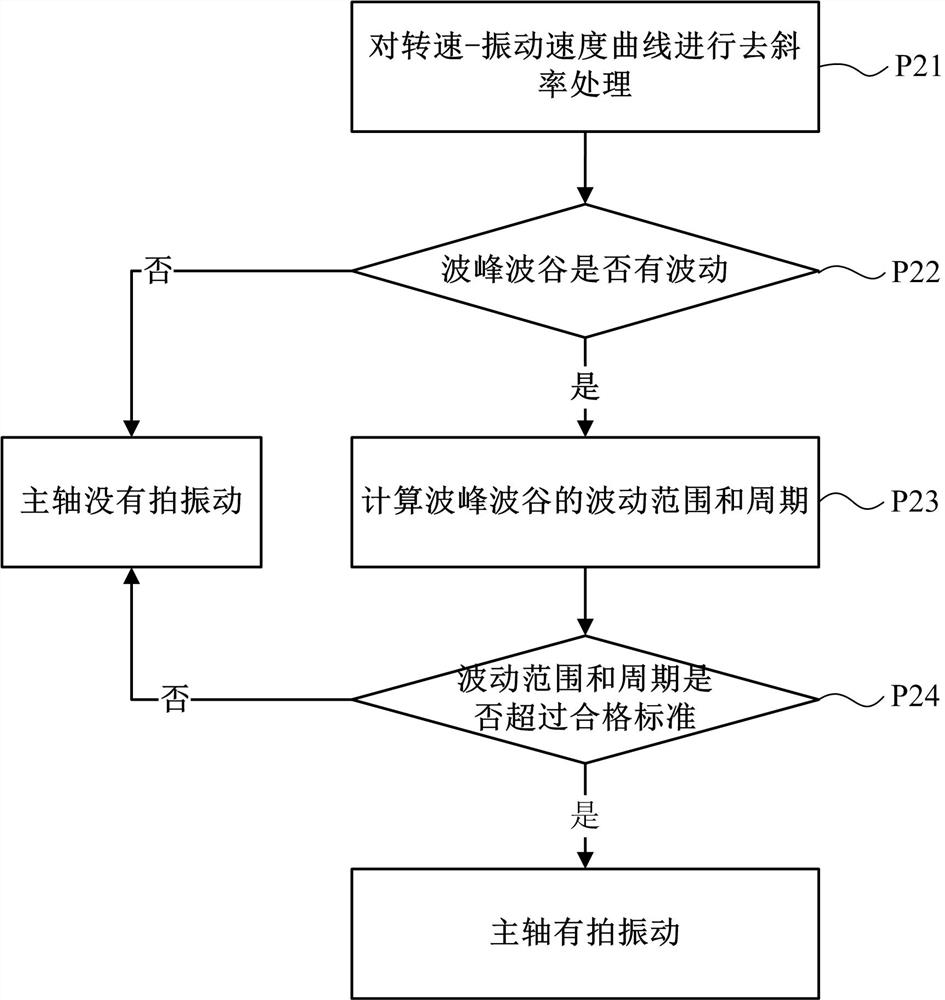

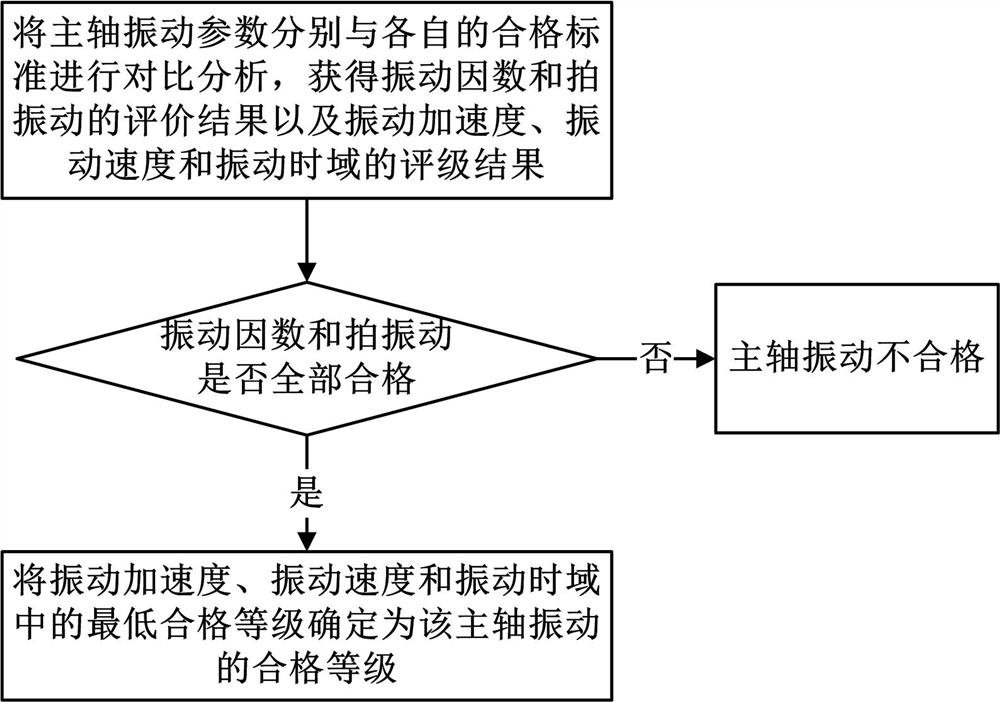

[0046] Step 200, performing calculation conversion and data processing on the collected vibration signal, obtaining a main shaft vibration characteristic curve, and performing beat vibration analysis and vibration time domain analysis according to the main shaft vibration characteristic curve;

[0047] Wherein, the main shaft vibration characteristic curve includes a rotation speed-vibration acceleration curve, a rotation speed-vibration speed curve, a rotation speed-vibration factor curve, a time-vibration acceleration curve, and a time-vibration speed curve;

[0048] The data processing of vibration signals ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com