Straightness and roll angle error simultaneous measurement system

A straightness error, measurement system technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of measurement accuracy, small sensitive area, low sensing accuracy and resolution, and improve measurement sensitivity and linearity. High accuracy of range, straightness and roll angle errors, the effect of avoiding dead space gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

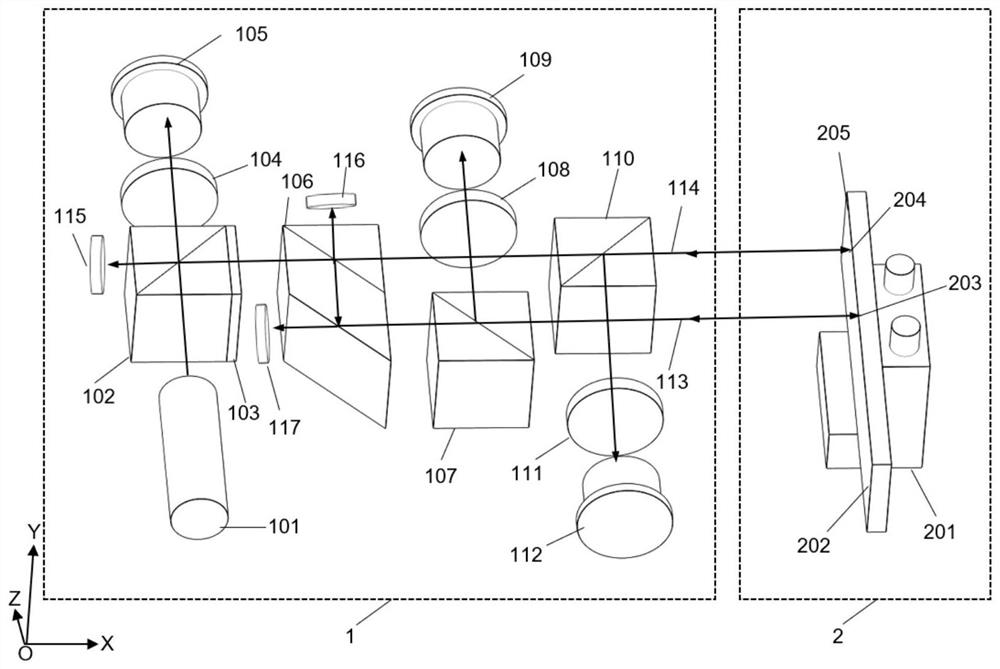

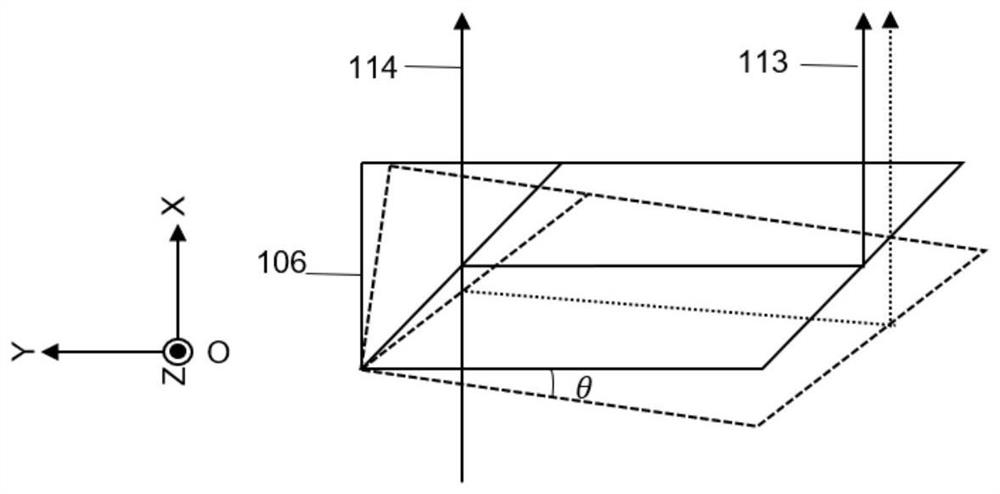

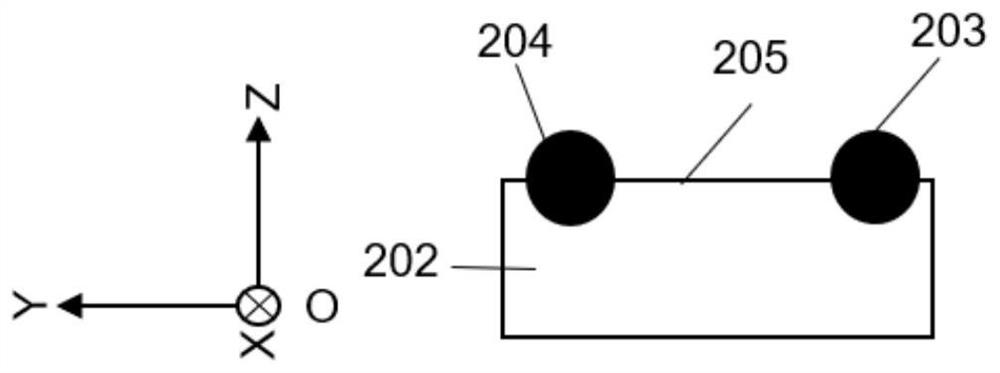

[0054] see figure 1 , the measurement system for simultaneously obtaining straightness and roll angle error in this embodiment is composed of a fixed unit 1 and a mobile measurement unit 2 to form a transceiver-integrated structure; the fixed unit 1 is installed on a fixed plane, and the mobile measurement unit 2 is installed on the mobile worktable. In the fixed unit 1, the parallel double beam method is adopted, and the combined prism formed by gluing a prism and a right-angle prism on the inclined plane is used to maintain the parallelism of the parallel beam, and the blade edge mirror 202 is adopted in the mobile measuring unit 2; When there is a vertical straightness error and a roll angle error on the moving table, the reflected edge of the blade edge mirror 202 cuts the measuring beam, changes the light intensity of the reflected beam, and detects the light intensity change information by the photodetector, thereby realizing a vertical straight line High precision measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com