Boiler fire tube cleaning device

A cleaning device and boiler fire technology, which is applied in boiler cleaning devices, lighting and heating equipment, fluid heaters, etc., can solve the problems of boiler fire tube carbon deposits and scaling affecting heat transfer efficiency, and improve heat transfer efficiency and use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

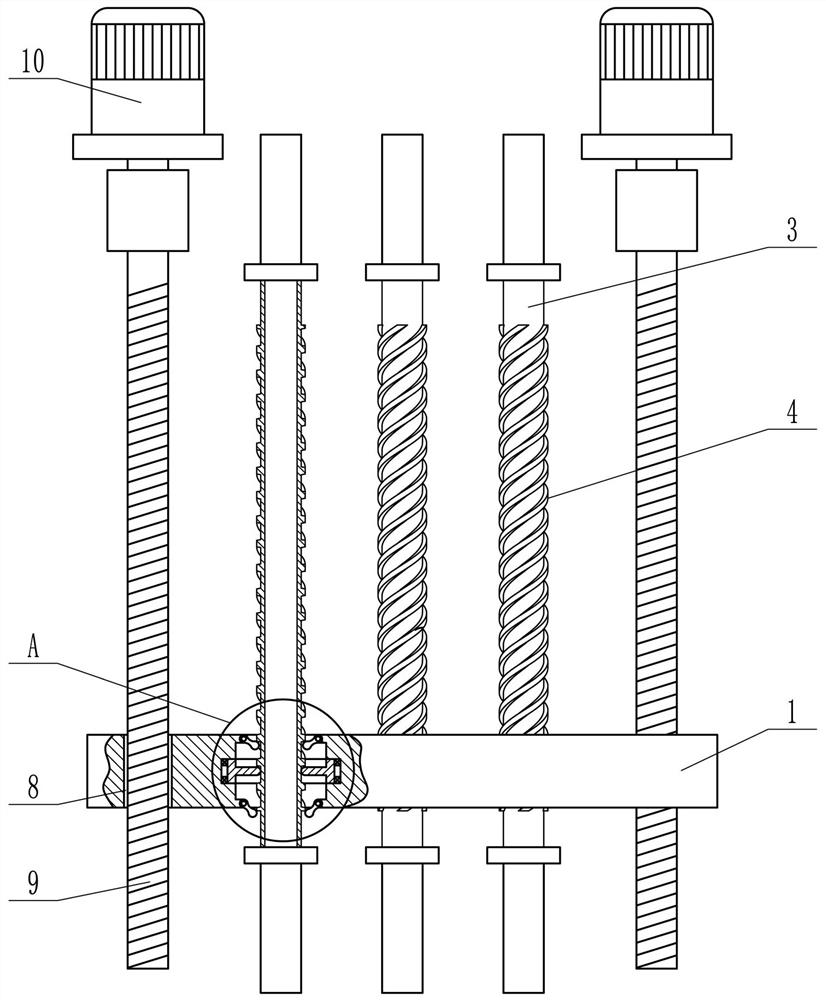

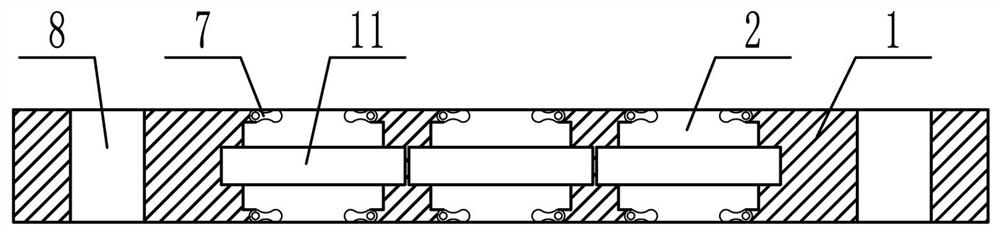

[0022] Depend on Figure 1 to Figure 7 Given, the present invention includes a horizontally placed horizontal plate 1, the middle area of the horizontal plate 1 is provided with a plurality of through holes 2 penetrating the upper and lower end surfaces of the horizontal plate 1, and a vertically placed fire tube is inserted into each through hole 2 3. The horizontal plate 1 can reciprocate up and down along the axis of the fire tube 3;

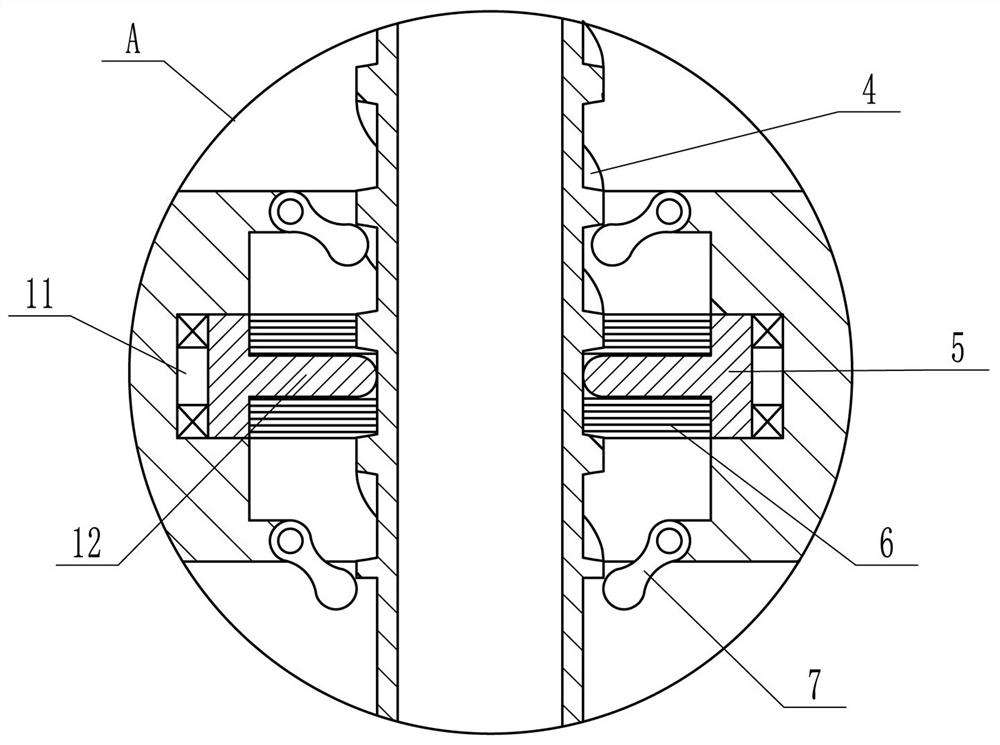

[0023] The outer edge surface of each fire tube 3 is provided with four helical strips 4. The four helical strips 4 on each fire tube 3 have the same rotation direction and helix angle and are evenly distributed around the axis of the fire tube 3. Each through hole 2 is rotatably connected with an annular block 5, the inner diameter of the annular block 5 is larger than the outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com