Hydraulic system, control method and wheel excavator

A hydraulic system and hydraulic technology, applied in the field of wheeled excavators, can solve problems such as incompatibility with large flow control and small flow fine control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

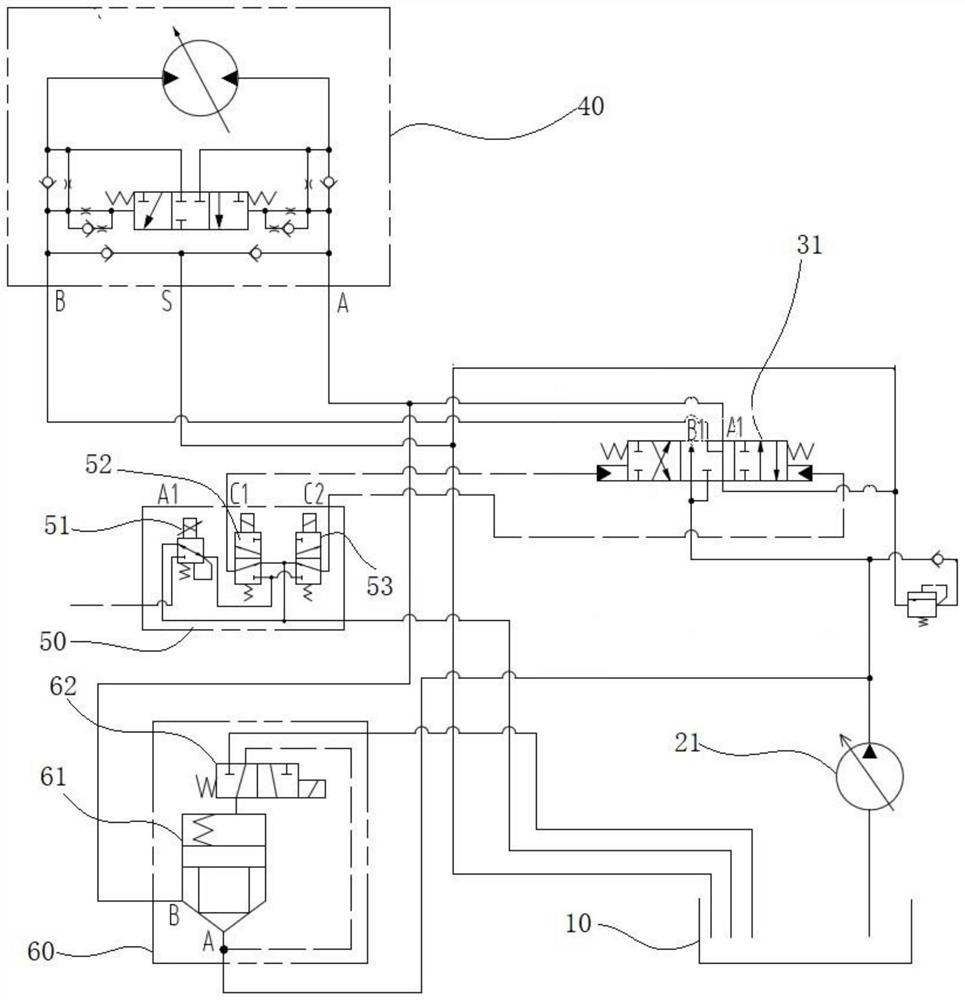

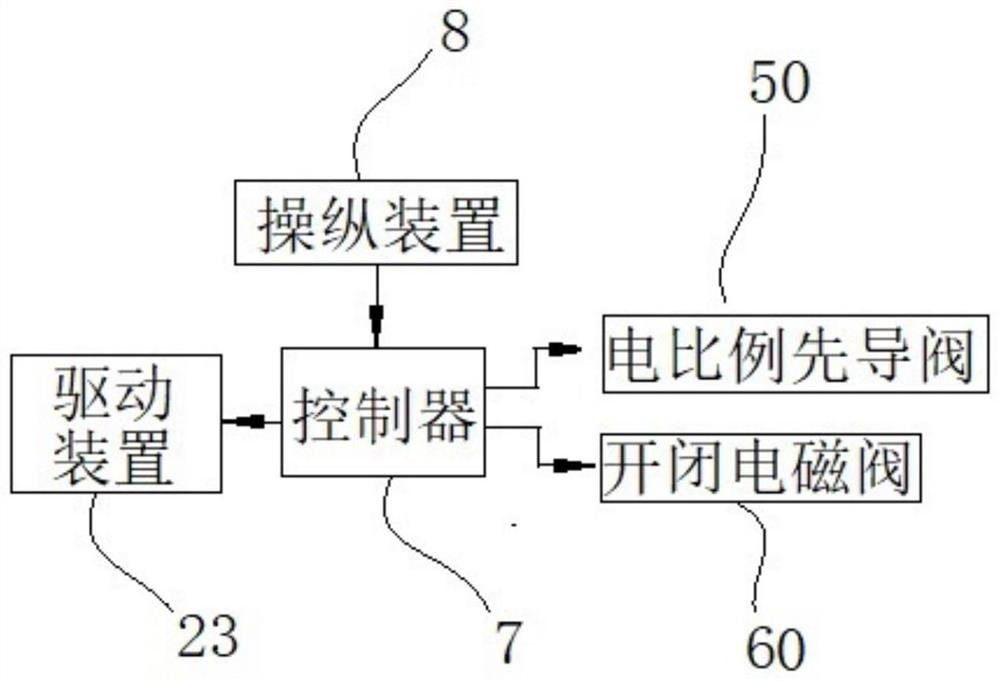

[0029] like figure 1 figure 2 As shown, the hydraulic system in this embodiment includes a hydraulic actuator 40, a pressure oil source, an electric proportional valve, a controller 7 for controlling the electric proportional valve, and a manipulation device 8 connected to the controller 7 for controlling the hydraulic actuator , opening and closing solenoid valve 60 and so on.

[0030] The pressure oil source consists of a hydraulic oil tank 10, a hydraulic pump 21 connected to the oil suction port and the hydraulic oil tank, and a power drive device 23 that drives the hydraulic pump 21 to rotate. The power drive device 23 is an electric motor or a fuel engine, and the speed of the power drive device 23 can be controlled by controlling The rotational speed of the hydraulic pump 21 is controlled to adjust the flow rate of the hydraulic pump 21 within a certain range.

[0031]The electro-proportional valve 3 consists of a hydraulically controlled main valve 31 and an electro...

Embodiment 2

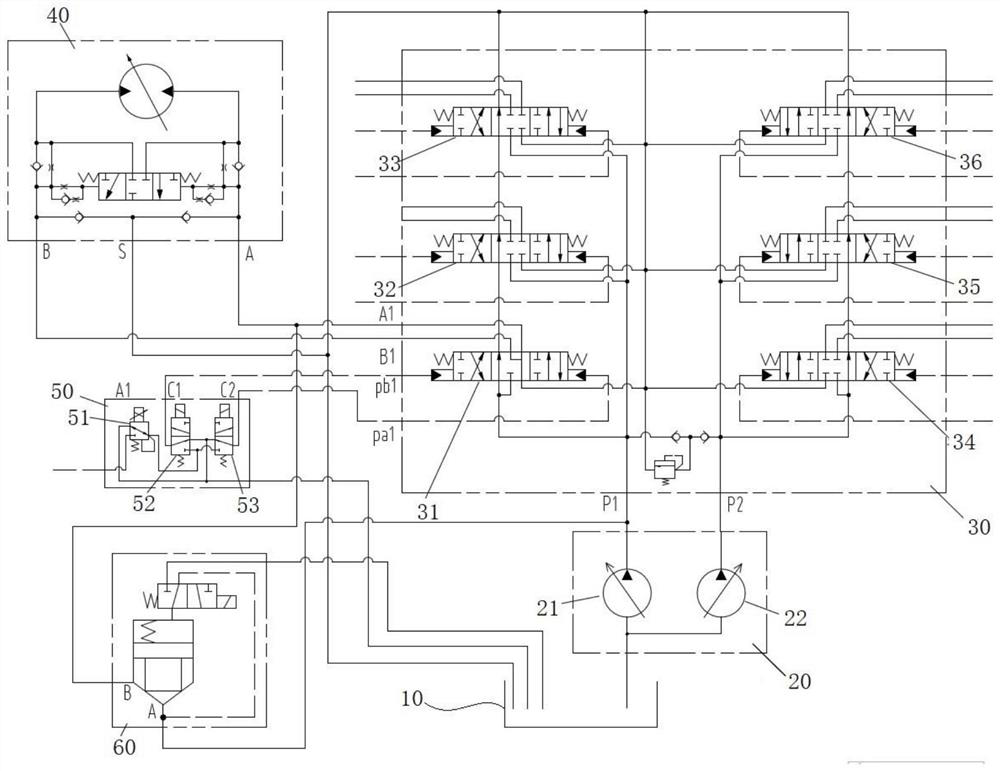

[0049] image 3 A part of the oil circuit in the hydraulic system of a wheeled excavator is shown. The hydraulic system in the traveling part of the wheeled excavator is the hydraulic system in the first embodiment, that is, the hydraulic actuator 40 in the first embodiment is the traveling motor of the excavator, and the hydraulic pump 21 and the second hydraulic pump 22 constitute a double pump The oil supply assembly 20, the main hydraulic control valve 31 is the main valve of the traveling wheel, and it is connected with the main valve of the rotary joint 32, the main valve of the arm joint 33, the main valve of the boom joint 36, the main valve of the bucket joint 35, the main valve of the bulldozer joint The main valve 34 constitutes the main control valve assembly 30 , wherein the hydraulic control main valve 31 and the main valve 32 of the rotary joint and the main valve of the stick joint 33 are supplied with oil by the hydraulic pump 21 ; the main valve of the boom j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com