exhaust return valve

An exhaust gas recirculation valve and exhaust gas recirculation technology, which are applied in the direction of exhaust gas recirculation, charging system, combustion engine, etc., can solve the problem that the EGR gas flow cannot be precisely controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

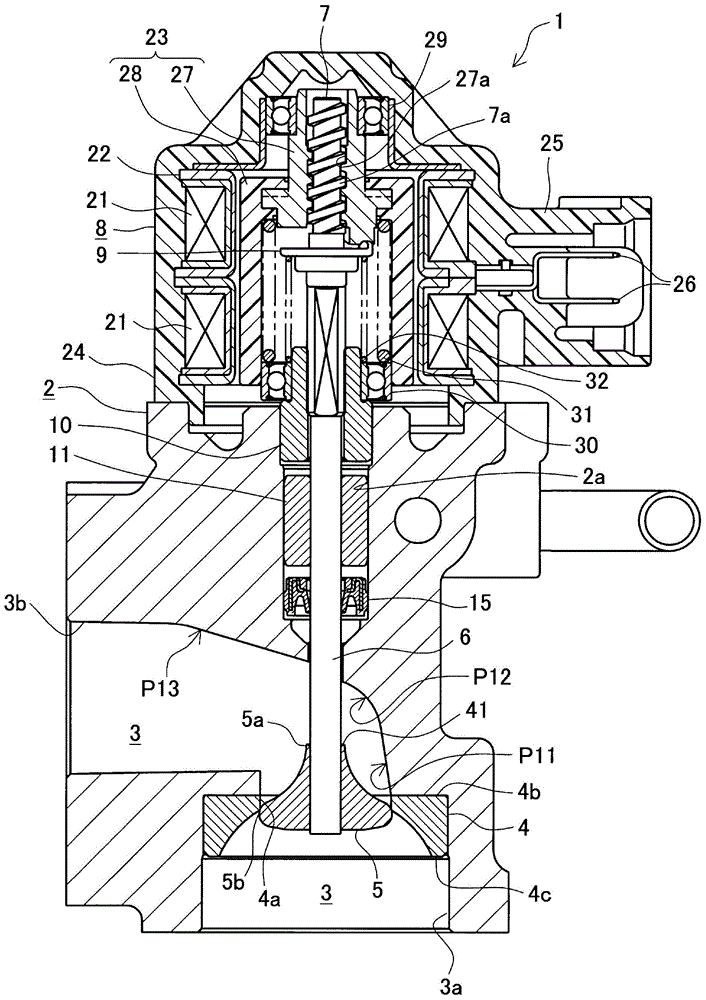

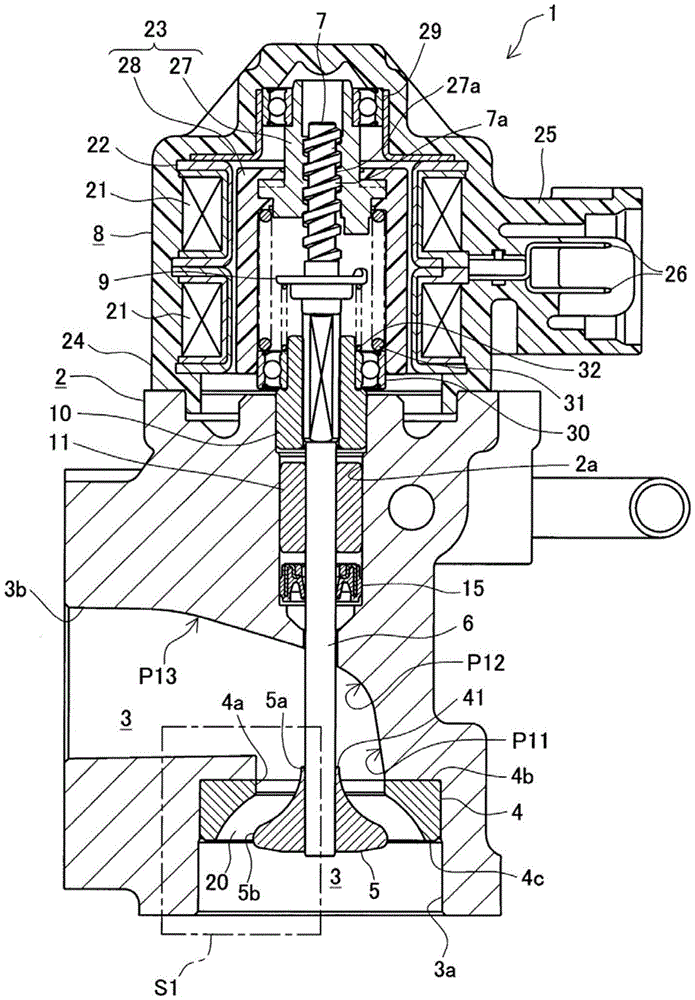

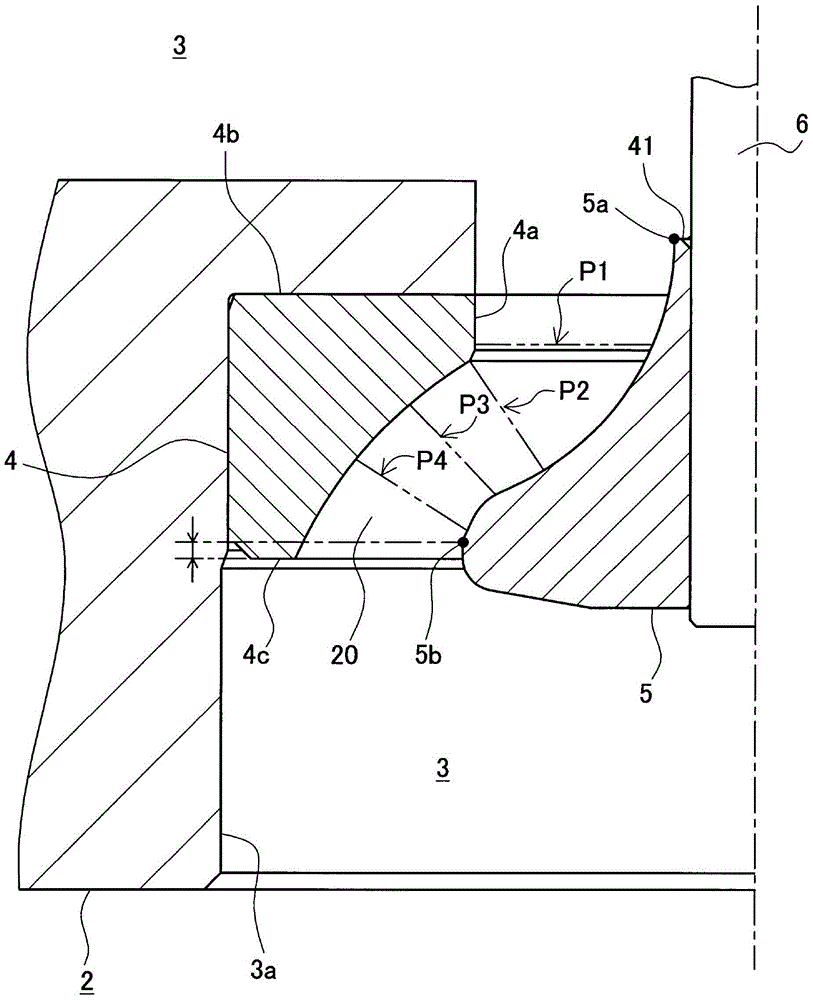

[0035] Hereinafter, an embodiment of an exhaust gas recirculation valve (EGR valve) according to the present invention will be described in detail with reference to the drawings.

[0036] figure 1 The EGR valve 1 in a fully closed state is shown by a front sectional view. figure 2 The EGR valve 1 in a fully open state is shown by a front sectional view. image 3 Represented by enlarged cross-sectional view figure 2 The part surrounded by the dotted four-frame S1. The EGR valve 1 is provided in an EGR passage for returning a part of the exhaust gas discharged from the engine to the intake passage as EGR gas, and is used for adjusting the flow rate of the EGR gas.

[0037] Such as figure 1 , figure 2 As shown, the EGR valve 1 includes a casing 2; a flow path 3 of EGR gas, which is formed in the casing 2; a valve seat 4, which is arranged in the middle of the flow path 3; a valve core 5, which can be placed on the valve seat 4 The metering part 20 of EGR gas is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com