Processing technology of natural ochre mineral pigment for ore color painting

A technology of mineral pigments and processing technology, applied in the direction of fibrous fillers, dyeing physical treatment, etc., can solve the problem that the research, development and use of mineral pigments are limited to the mode of master-to-apprentice, so as to avoid tedious and time-consuming and labor-intensive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

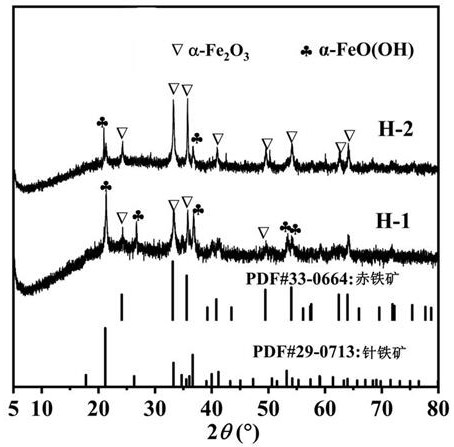

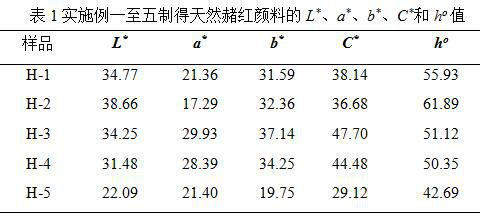

Embodiment 1

[0025] Embodiment 1: The natural ochre red ore is crushed to a particle size of 4 mm by a crusher, and then processed to a particle size of 40 mesh by Raymond mill. Take 180 kg of powder ore sample and add it to 500 L of water, and grind it with a sand mill. The obtained wet-grinding slurry was subjected to solid-liquid separation by a filter press (the water content of the filter cake was 36%), and the obtained filter cake was subjected to mechanical stirring, pulping and washing, and then pressure filtration again, and the solid-liquid mass ratio of the washing was controlled to be 35%. , the moisture content of the final filter cake obtained is 38%. Finally, the obtained filter cake was dried and pulverized to 150 mesh in a powerful dryer, then sent to a rotary kiln, roasted at 300ºC for 60 min, and then bagged. The sample was marked as H-1. L * , a * , b * See Table 1 for color parameters.

Embodiment 2

[0026] Embodiment 2: The natural ochre red ore is crushed to a particle size of 5 mm by a crusher, and then processed to a particle size of 60 mesh by Raymond mill. Take 100 kg of powdered ore sample and add it to 600 L of water, and grind it with a sand mill. The obtained wet grinding slurry was subjected to solid-liquid separation by a filter press (the water content of the filter cake was 38%), and the obtained filter cake was subjected to mechanical stirring, pulping and washing, and then pressure filtration again, and the solid-liquid mass ratio of the washing was controlled to be 37%. , the moisture content of the final filter cake obtained is 40%. Finally, the obtained filter cake is dried and pulverized to 200 mesh in a powerful dryer, and the sample is marked as H-2. L * , a * , b * See Table 1 for color parameters.

Embodiment 3

[0027]Example 3: The natural ochre red ore crusher was crushed to a particle size of 3.5 mm, and then processed by Raymond mill to a particle size of 100 mesh. Take 180 kg of powdered ore sample and add it to 550 L of water, and grind it with a sand mill. The obtained wet grinding slurry is subjected to solid-liquid separation by a filter press (the water content of the filter cake is 40%), and the obtained filter cake is subjected to mechanical stirring, pulping and washing, and then pressure filtration again, and the solid-liquid mass ratio of washing is controlled to be 40%. , the moisture content of the final filter cake obtained is 45%. Finally, the obtained filter cake was dried and pulverized to 160 mesh in a powerful dryer and then directly sent to the rotary kiln, roasted at 700ºC for 60 min and then bagged. L * , a * , b * See Table 1 for color parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com