Busbar glue winding device integrating glue feeding and glue winding and working method of busbar glue winding device

A technology of wrapping glue and busbars, which is applied in the directions of sending objects, transportation and packaging, thin material processing, etc., can solve the problems of sealing parts that affect the tightness of the connection, easy to produce wrinkles, easy to stick to the tape, etc., to improve the flatness. and tightness, reducing workload, maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

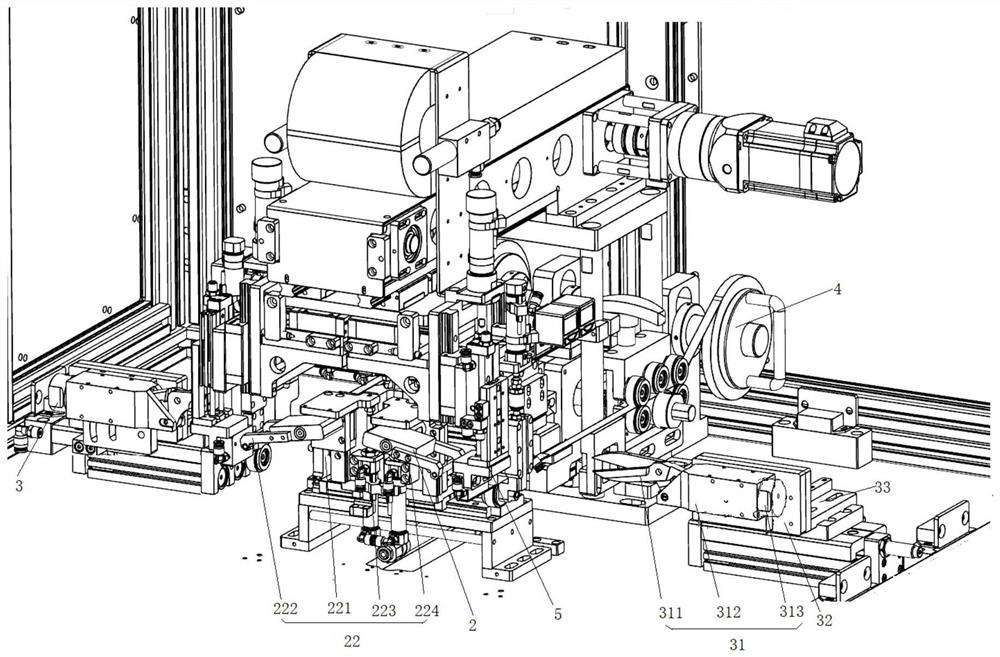

[0061] As shown in the figure, a busbar glue wrapping device integrating glue feeding and wrapping includes: a tape conveying device 4 and an automatic glue wrapping device 5. The tape conveying device 4 and the automatic glue wrapping device 5 are both located in On the workbench, the lower part of one end of the automatic glue wrapping device 5 is connected to the workbench through a group of uprights 402, and the automatic glue wrapping device 5 is arranged above the tape conveying device 4;

[0062] The adhesive tape conveying device 4 includes an adhesive tape placing rack 41, an adhesive tape conveying mechanism 42 and a conveying auxiliary mechanism 43. The adhesive tape placing rack 41 is arranged on a workbench, and a side of the adhesive tape placing rack 41 is installed on the workbench. Bottom plate 401, the tape conveying mechanism 42 is arranged on the mounting bottom plate 401, and a group of uprights 402 is arranged on the side of the mounting bottom plate 401 w...

Embodiment 2

[0076] The structure of the tape conveying device 4 and the automatic gluing device 5 described in this embodiment is the same as that in the first embodiment.

[0077] like figure 1 , 2 Shown is a busbar glue wrapping device integrating glue feeding and wrapping, further comprising: a tape smoothing device 2 and a tape cutting device 3, the tape smoothing device 2 is arranged in front of the tape conveying device 4 , and is located below the automatic glue wrapping device 5 , and the tape cutting device 3 is arranged on both sides of the tape smoothing device 2 .

[0078] like Figure 13-15 The tape smoothing device 2 shown includes a mounting seat 21, a set of smoothing devices 22 and a smoothing drive mechanism 23, wherein the smoothing device 22 includes a smoothing mounting seat 221, a smoothing mechanism 222 and a smoothing pressing mechanism 223, a set of guide rails 24 are arranged on the mounting seat 21, the smoothing mounting seat 221 is connected to the guide ra...

Embodiment 3

[0083] The tape leveling device 2, tape cutting device 3, tape conveying device 4 and automatic glue wrapping device 5 described in this embodiment are the same as the tape leveling device 2 and tape cutting device 3 in Embodiments 1 and 2. , The tape conveying device 4 and the automatic gluing device 5 have the same structure.

[0084] like Figures 19 to 23 Also shown is a busbar feeding and clamping device 1, the busbar feeding and clamping device 1 includes a product placement rack 12, a lift drive mechanism 13, a rotary clamping device 14 and an adsorption mechanism 15, the workbench 11 is provided with a set of guide rails 111, and a moving mechanism 16 is arranged below the product placement rack 12, the moving mechanism 16 is movably connected with the guide rails 111, and the elevating driving mechanism 13 is installed on the moving mechanism 16, and its output The end is connected with the product placing rack 12 , the rotating clamping device 14 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com