Wind turbine generator outer surface detection device and working method thereof

A technology for wind turbines and detection devices, which is applied to wind turbines, monitoring of wind turbines, engines, etc., can solve problems such as inability of flexible movement of detection devices, poor adsorption capacity of detection devices, poor carrying capacity, movement stability, obstacle-crossing ability, etc., to achieve Rapid maintenance detection, strong obstacle-surpassing ability, and improved adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

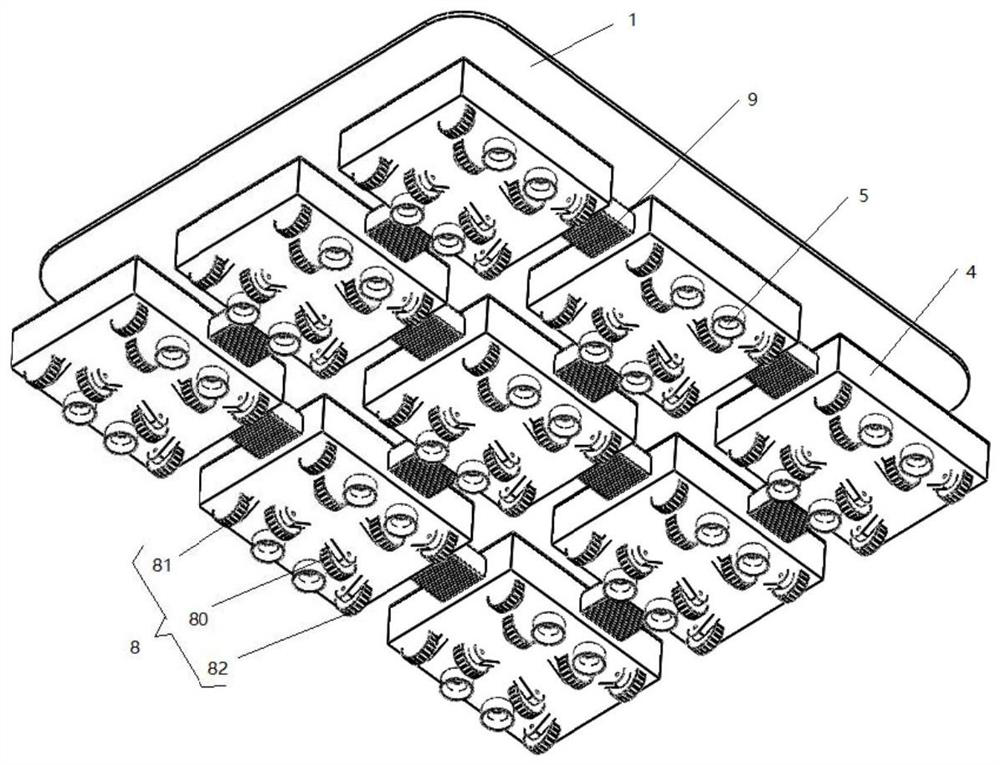

Embodiment 1

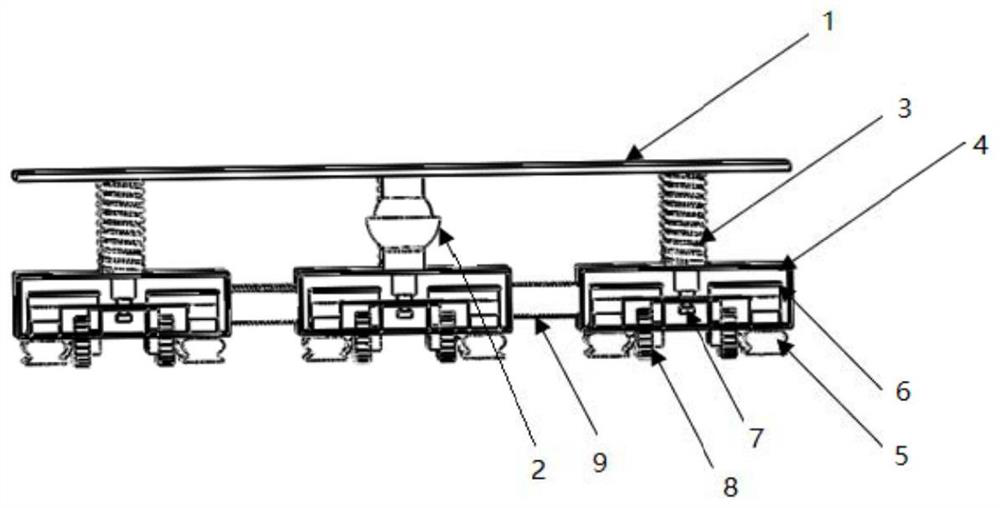

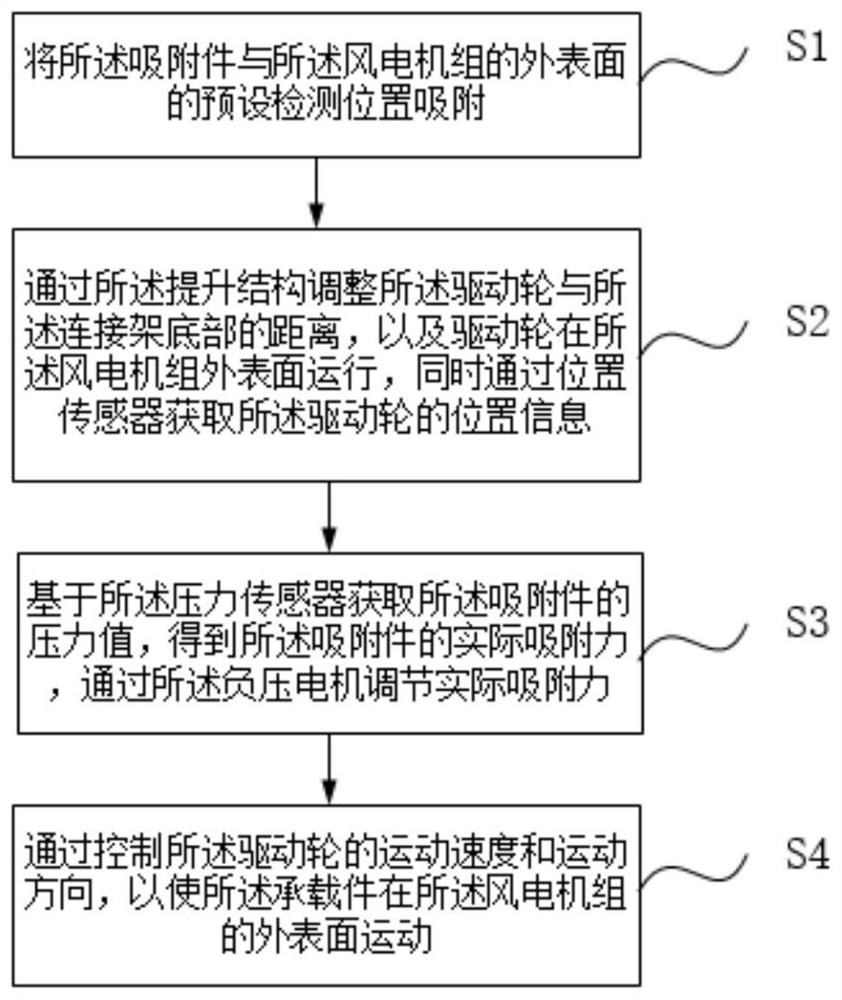

[0103] When the carrier 1 moves along the horizontal circumferential direction of the outer surface of the wind turbine:

[0104] The suction member 5 is adsorbed to the preset detection position of the outer surface of the wind turbine, and the driving wheel 8 is driven to go beyond the bottom of the connecting frame 4 by a certain distance through the lifting structure 7, and the position information is monitored in real time to ensure that the driving wheel is in horizontal circumferential movement. 8 can be in contact with the outer surface of the wind turbine in real time, and the position information of the driving wheel 8 can be detected by the position sensor. At the same time, change the negative pressure of the adsorption part 5, measure the real negative pressure of the adsorption part 5 through the pressure gauge, and then obtain the real-time negative pressure feedback of the negative pressure of the adsorption part 5 through the relationship between the negative p...

Embodiment 2

[0106] When the carrier 1 moves along the vertical and horizontal direction of the outer surface of the wind turbine:

[0107] The adsorption member 5 is adsorbed to the preset detection position on the outer surface of the wind turbine, and the driving wheel 8 is driven to retract a certain distance from the bottom of the connecting frame 4 through the lifting structure 7, and the position information is monitored in real time to ensure that the driving wheel 8 moves in the vertical and horizontal direction. It can contact with the outer surface of the wind turbine in real time, and detect the position information of the driving wheel 8 through the position sensor. At the same time, change the negative pressure of the adsorption part 5, measure the real negative pressure of the adsorption part 5 through the pressure gauge, and then obtain the real-time negative pressure feedback of the negative pressure of the adsorption part 5 through the relationship between the negative pre...

Embodiment 3

[0109] When the carrier 1 rotates along the outer surface of the wind turbine:

[0110] In the state of moving along the vertical and horizontal direction of the outer surface of the wind turbine, when the moving speed of the first driving wheel 80 located in the middle of the connecting frame 4 is kept constant, the second driving wheel 81 located on the left side of the first driving wheel 80 The movement speed of the first driving wheel 80 is greater than the movement speed of the first driving wheel 80 and reaches a reasonable constant value. A reasonable constant value, that is, to realize the speed difference, the carrier 1 rotates clockwise by a certain angle, thereby realizing multi-angle operation. Improve the device's obstacle-surmounting ability and flexible steering ability. At the same time, the negative pressure motor is adjusted so that the device as a whole passes through the adsorption member 5, which can not only adsorb and fit on the curved surface, but als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com