Automatic cutting process for curtain fabric processing

A curtain cloth and automatic technology, which is applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting the smoothness of the fabric, the injury of the respiratory tract of personnel, and the low degree of intelligence of the automatic curtain cutting equipment, so as to improve the laying efficiency , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

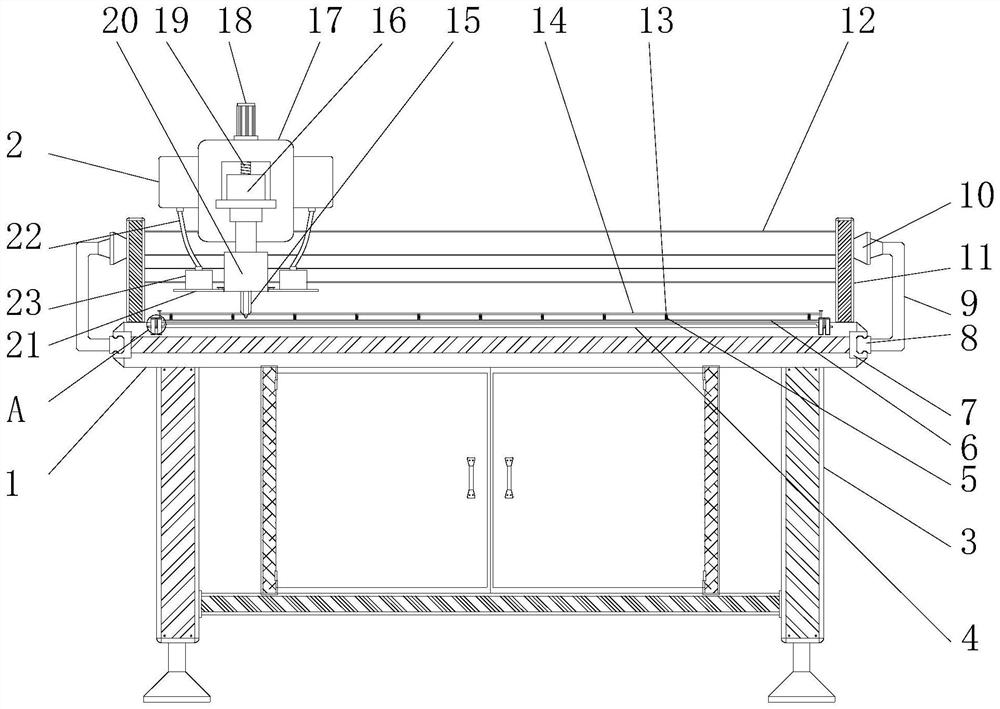

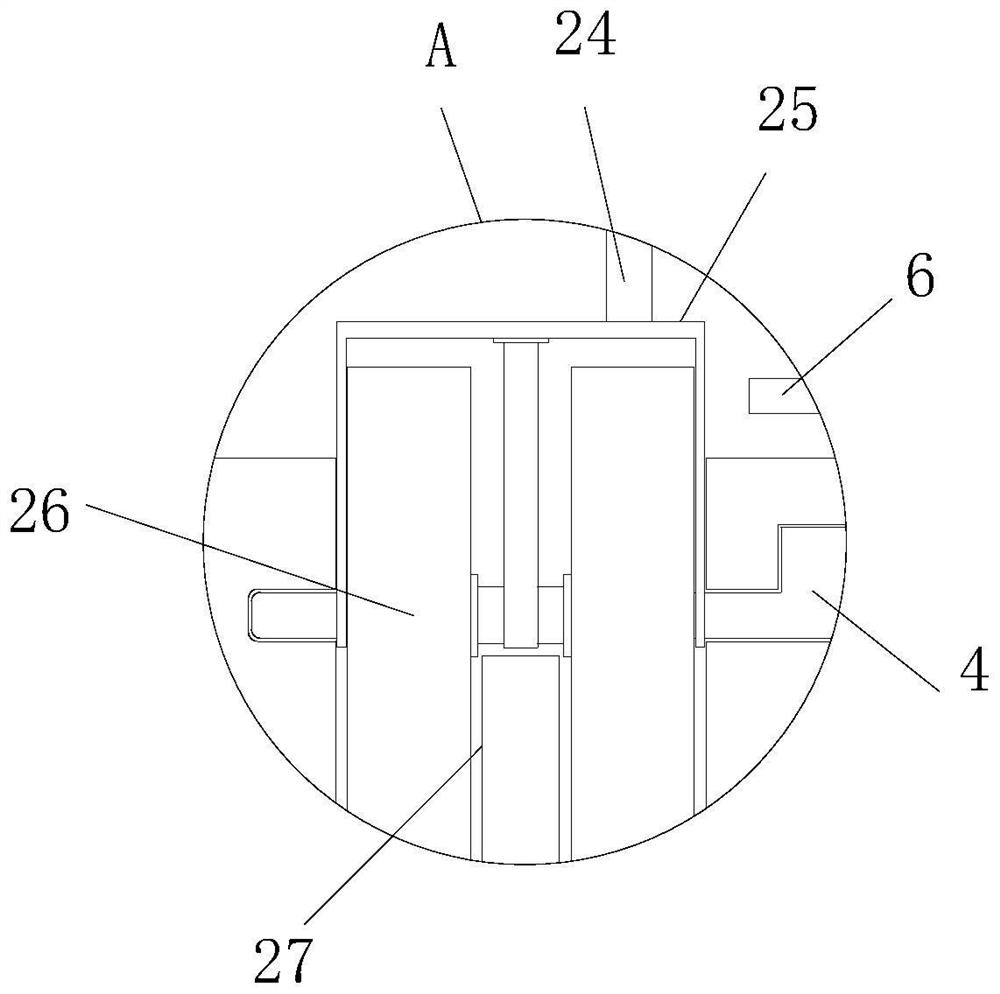

[0045] like figure 1 As shown, an automatic cutting process for curtain fabric processing includes a fixed guide rail 7, which is fixedly arranged on the left and right sides of the processing table 1, and a guide slider 8 is arranged inside the fixed guide rail 7, and one side of the guide slider 8 is provided. A support rod 9 is provided, a fixing member 10 is installed at the end of the supporting rod 9, and a sliding plate 11 is arranged on the inner side of the fixing member 10, and a transverse sliding rail 12 is arranged on the inner side of the sliding plate 11, and a transverse sliding rail 12 is installed above the transverse sliding rail 12. Block 17, the lateral slider 17 realizes sliding movement on the lateral slide rail 12, and the lateral slide rail 12 and the slide plate 11 are perpendicular to each other, and the slide plate 11 is realized in the fixed guide rail 7 through the support rod 9, the fixed part 10, and the guide slide block 8 Sliding movement; the...

Embodiment 2

[0049] The scheme in the first embodiment will be further introduced below in conjunction with the specific working mode, see the following description for details:

[0050] A process for automatic cutting equipment for curtain fabric processing, comprising the following steps:

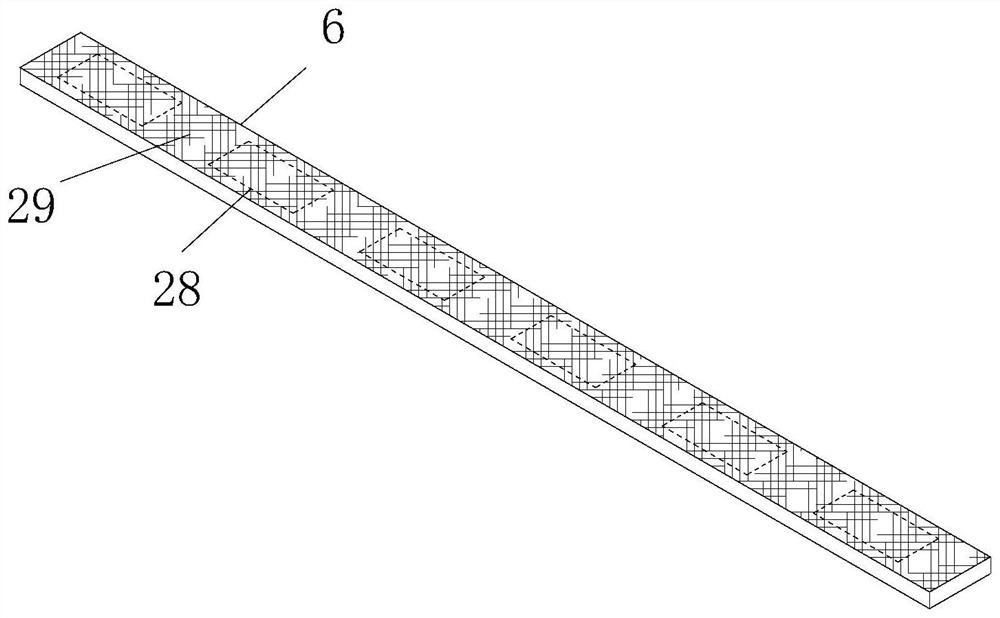

[0051] S1. Unfold the cloth and place it under the clamping plate 6, and connect the electromagnet adsorption plate 4 to electricity, so that the electromagnet adsorption plate 4 and the adsorption magnet 28 in the clamping plate 6 are attracted to each other. The cloth is clamped;

[0052] S2. The sliding roller 26 slides on the limit chute 27, and drives the electromagnet adsorption plate 4 to move backward, and under the attraction of the magnet, pulls the clamping plate 6 to move synchronously backward, and the sliding roller 26 is moving At the same time, the synchronous moving member 25 will drive the lifting rod 14 to move backward through the connecting plate 24, so that the clamping plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com