Preparation method of copper-antimony monatomic alloy catalyst and application of copper-antimony monatomic alloy catalyst in reduction of carbon dioxide

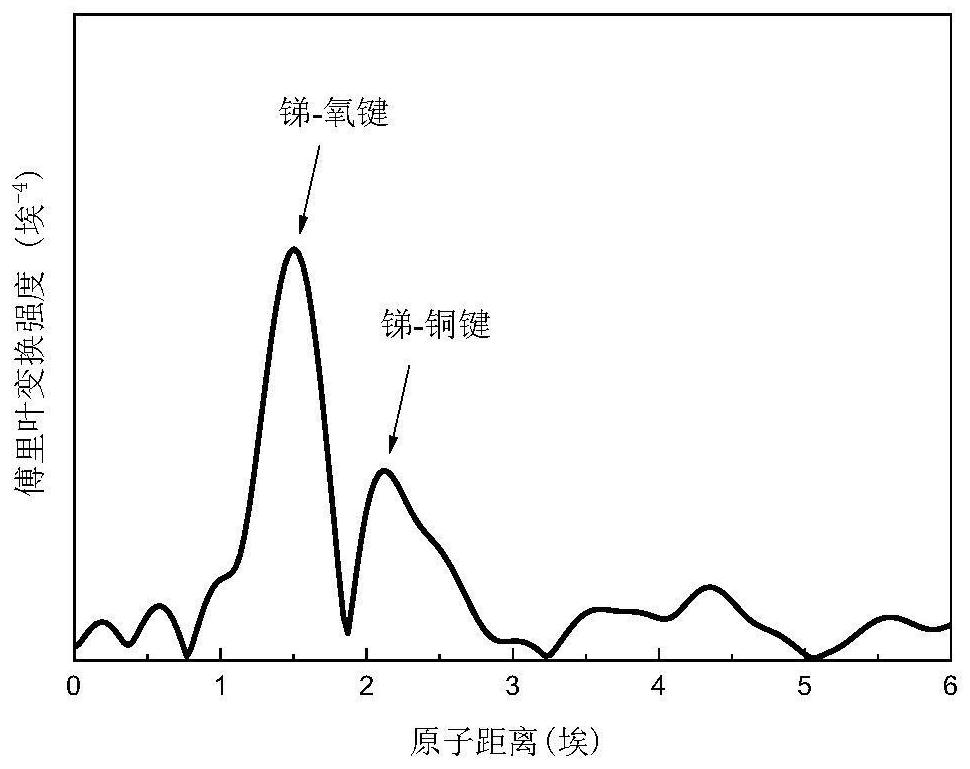

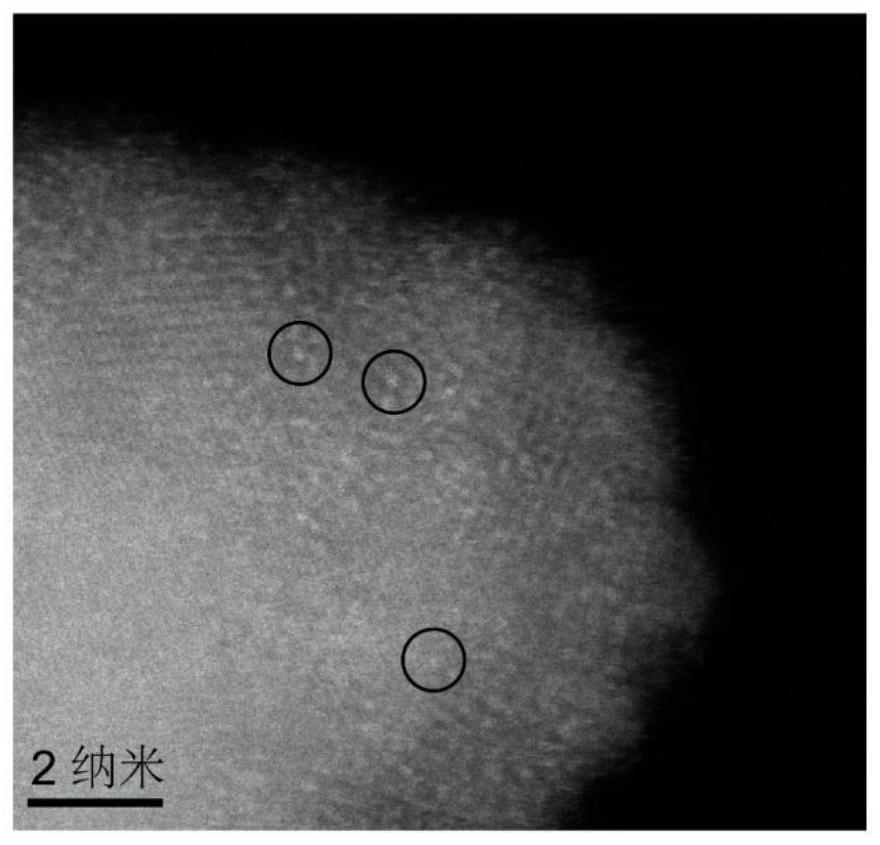

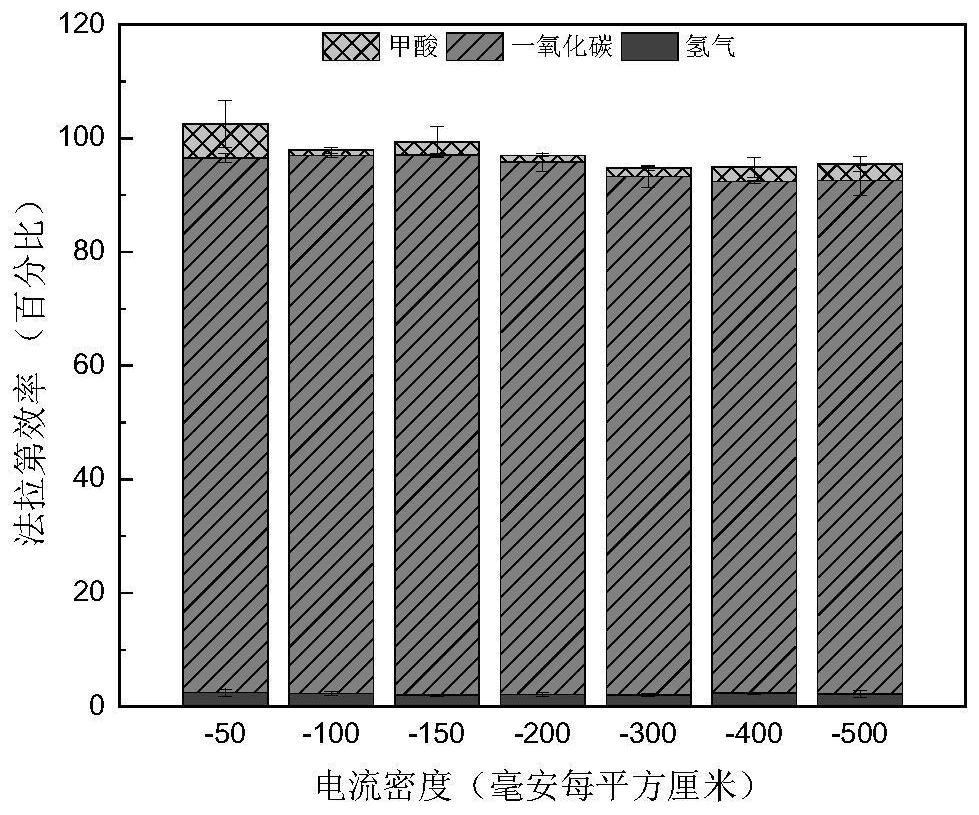

A catalyst, copper-antimony single technology, applied in metal processing equipment, transportation and packaging, nanotechnology for materials and surface science, etc., can solve the problems of low selectivity, easy generation of multi-carbon products, etc., and achieve a simple synthesis method. , the effect of excellent electrochemical carbon dioxide reduction performance, high carbon monoxide selectivity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment prepares a copper-antimony single-atom alloy nano-catalyst, and the specific steps are as follows:

[0038] Disperse 1 mmol of antimony chloride in 20 ml of deionized water and add 3 mmol of citric acid to obtain mixed solution A; disperse 20 mmol of cupric chloride dihydrate in 20 ml of deionized water to obtain solution B; take 3.2 ml of mixed solution A, 2 ml of solution B, 1 ml of hydrochloric acid with a concentration of 3 mol per liter and 13.8 ml of deionized water, mixed to obtain 20 ml of mixed solution C; the mixed solution C was allowed to stand in an ice bath at -5°C for 60 minutes , and then poured into 10 ml of sodium borohydride aqueous solution with a concentration of 1 mol per liter at a rate of 10 ml per second to obtain mixed solution D; after mixed solution D was allowed to stand at room temperature for 2 hours, it was rotated at 10,000 rpm. , centrifugal separation for 10 minutes, the obtained product was ultrasonically washed...

Embodiment 2

[0047] The present embodiment prepares a copper-antimony single-atom alloy nano-catalyst, and the specific steps are as follows:

[0048] Disperse 1 mmol of antimony chloride in 20 ml of deionized water and add 3 mmol of citric acid to obtain mixed solution A; disperse 20 mmol of cupric chloride dihydrate in 20 ml of deionized water to obtain solution B; take 1.2 ml of mixed solution A, 2 ml of solution B, 1 ml of hydrochloric acid with a concentration of 3 mol per liter and 15.8 ml of deionized water, mixed to obtain 20 ml of mixed solution C; the mixed solution C was allowed to stand in an ice bath at -5°C for 60 minutes , and then poured into 10 ml of sodium borohydride aqueous solution with a concentration of 1 mol per liter at a rate of 10 ml per second to obtain mixed solution D; after mixed solution D was allowed to stand at room temperature for 2 hours, it was rotated at 10,000 rpm. , centrifugal separation for 10 minutes, the obtained product was ultrasonically washed...

Embodiment 3

[0056] The present embodiment prepares a copper-antimony single-atom alloy nano-catalyst, and the specific steps are as follows:

[0057] Disperse 1 mmol of antimony chloride in 20 ml of deionized water and add 3 mmol of citric acid to obtain mixed solution A; disperse 20 mmol of cupric chloride dihydrate in 20 ml of deionized water to obtain solution B; take 8 Milliliter of mixed solution A, 2 milliliters of solution B, 1 milliliter of hydrochloric acid with a concentration of 3 mol per liter, and 9 milliliters of deionized water were mixed to obtain 20 milliliters of mixed solution C; mixed solution C was allowed to stand in an ice bath at -5°C for 60 minutes , and then poured into 10 ml of sodium borohydride aqueous solution with a concentration of 1 mol per liter at a rate of 10 ml per second to obtain mixed solution D; after mixed solution D was allowed to stand at room temperature for 2 hours, it was rotated at 10,000 rpm. , centrifugal separation for 10 minutes, the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com