Automatic spraying equipment

A technology of automatic spraying and equipment, which is applied in the direction of spraying booths, spraying devices, and cleaning methods using liquids, etc. It can solve the problems of lower paint rate than others, troublesome equipment cleaning, and waste of paint, so as to achieve uniform paint film thickness and reduce Long spraying time and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

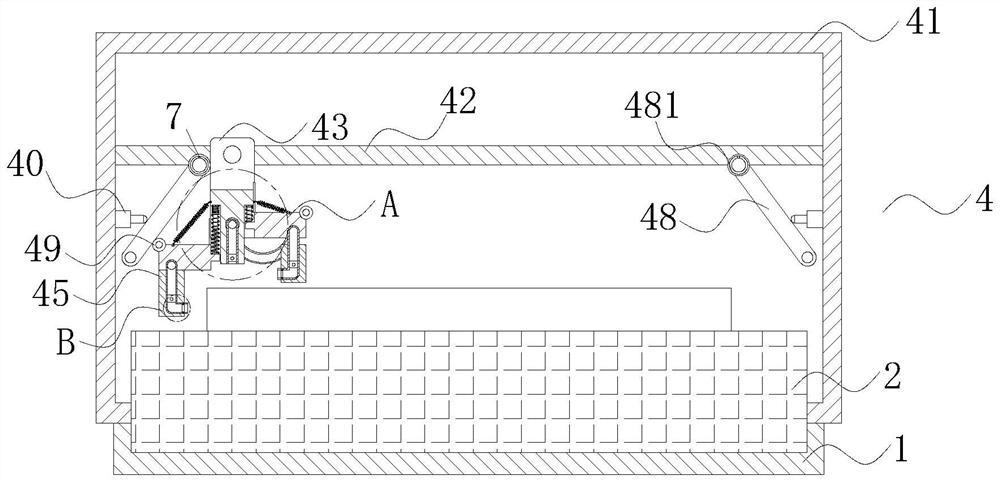

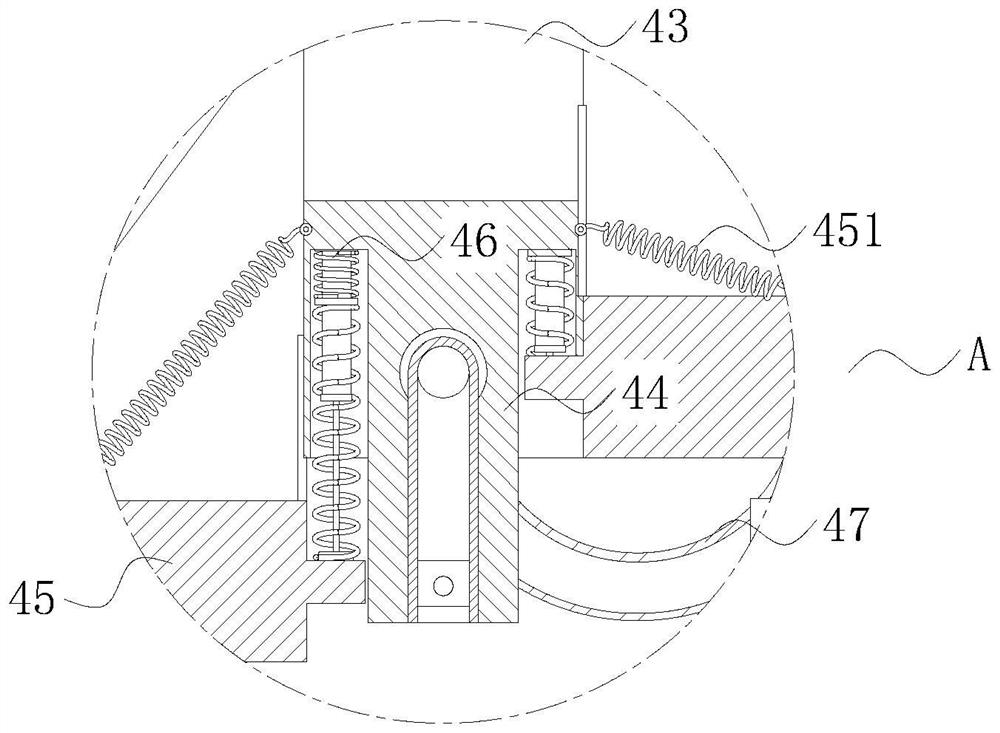

[0038] As an embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the spraying mechanism 4 includes a first housing 41, a rail 42, a moving assembly 43, a first spray gun 44, a second spray gun 45, a second spring 451, a first spring 46, a spray pipe 47, a limit plate 48 and roller 49;

[0039] A first housing 41 is fixedly connected to the upper end of the base 1 near the control assembly 3, a rail 42 is fixedly connected to an inner surface of the first housing 41, and a moving component 43 is slidably connected to the outer surface of the rail 42. A first spray gun 44 is fixedly connected to the lower end of the moving assembly 43 , a second spray gun 45 is symmetrically slidably connected to the outer surface of the lower end of the first spray gun 44 , and a first spring 46 is fixedly connected to one end of the second spray gun 45 . The upper end of 46 is fixedly connected to the first spray gun 44, the outer surface of the second spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com