Composite piezoelectric film for inducing bone regeneration as well as preparation method and application of composite piezoelectric film

A piezoelectric film and bone regeneration technology, applied in the field of medical materials, can solve problems such as changes in bone repair materials, achieve the effects of accelerating bone regeneration, improving anti-inflammatory effects, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a simple, efficient and stable preparation method of a composite piezoelectric film for inducing bone regeneration, which overcomes the problems of poor biocompatibility of other bone repair materials and the inability to biomimulate the electrochemical microenvironment around natural bone tissue.

[0029] The preparation method of the present invention comprises the following steps:

[0030] 1. Prepare 100 mL of 10 mM tris solution, add an appropriate amount of dilute hydrochloric acid, and adjust the pH to 8-9;

[0031] 2. Weigh a certain amount of graphene oxide and dopamine hydrochloride, and add them to the tris solution prepared above, and ultrasonically disperse them uniformly. The ultrasonically dispersed solution was uniformly stirred at a constant temperature for a period of time, and then vacuum-dried overnight to obtain the prepared GO-PDA particles;

[0032] 3. Weigh a certain mass of the prepared GO-PDA particles, add them into an o...

Embodiment 1

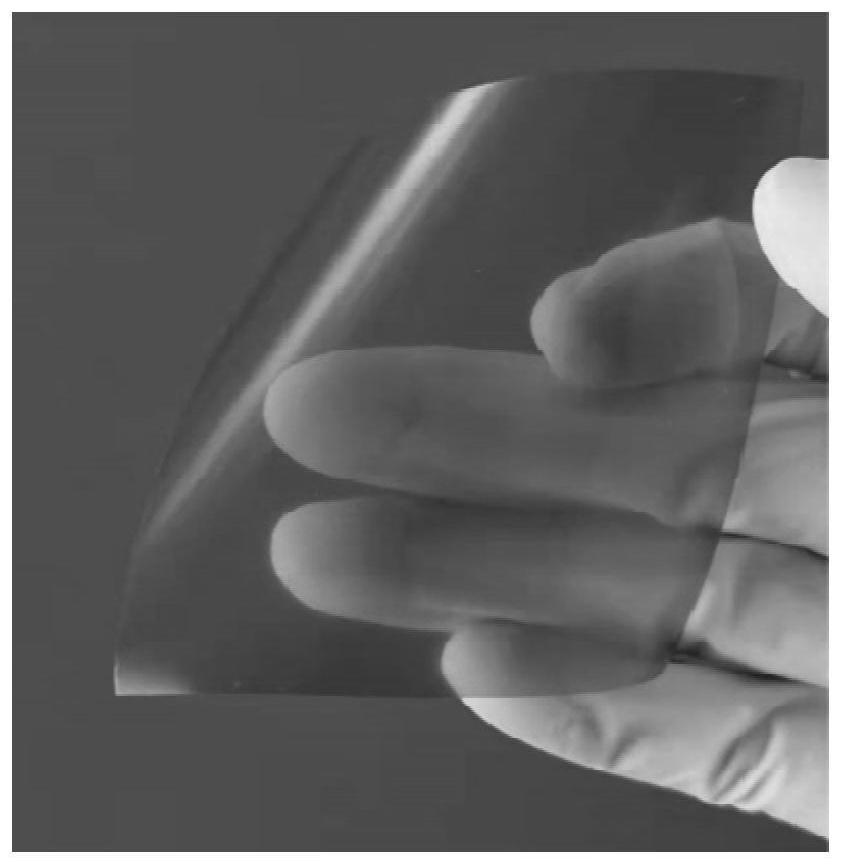

[0048] Prepare 100 mL of 10 mM tris solution, adjust the pH to 8.5 with dilute hydrochloric acid, add 10 mg of GO and 20 mg of dopamine hydrochloride, ultrasonically disperse for 1 h, then uniformly stir at 60 °C for 48 h, and finally put the mixed solution into a vacuum of 80 °C Dry oven overnight. The prepared GO-PDA powder was dispersed in dichloromethane to prepare a 2 mg / mL GO-PDA dispersion. 1 g of PVDF was weighed and dissolved in 10 mL of dichloromethane, and then 1.5 mL of GO-PDA dispersion was added to the PVDF solution and stirred for 5 hours. After the stirring was complete, the solution was transparent, and the solution was spread on a glass plate and dried in a vacuum drying oven at 70° C. overnight. The next day, the dried films were annealed at 90 °C for 2 h. After the annealing is complete, the film is peeled off to a thickness of 60 μm. Finally, corona polarization was carried out at 10kv for 30min. After waiting for polarization, the composite piezoelect...

Embodiment 2

[0050] Prepare 100 mL of 10 mM tris solution, adjust the pH to 8.5 with dilute hydrochloric acid, add 10 mg of GO and 50 mg of dopamine hydrochloride, ultrasonically disperse for 1 h, then uniformly stir at 60 °C for 48 h, and finally put the mixed solution into a vacuum of 80 °C Dry oven overnight. The prepared GO-PDA powder was dispersed in dimethyl sulfoxide to prepare a 3 mg / mL GO-PDA dispersion. 1 g of P(VDF-TrFE) was weighed and dissolved in 15 mL of dimethyl sulfoxide, and 2.5 mL of GO-PDA dispersion was added to the P(VDF-TrFE) solution and stirred for 6 hours. After the stirring was completed, the solution was spread on a glass plate and dried in a vacuum drying oven at 60°C overnight. The next day, the dried films were annealed at 100 °C for 2 h. After the annealing is complete, the film is peeled off to a thickness of 60 μm. Finally, corona polarization was carried out at 15kv for 60min. After waiting for polarization, the composite piezoelectric film can be pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

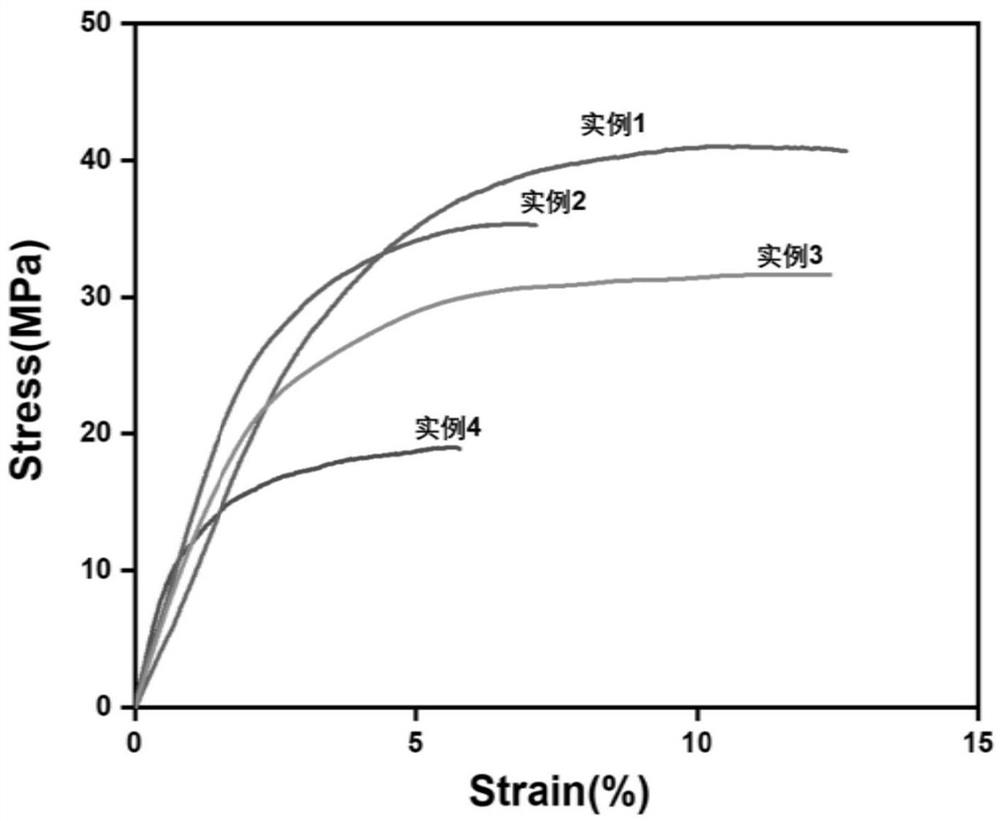

| tensile strength | aaaaa | aaaaa |

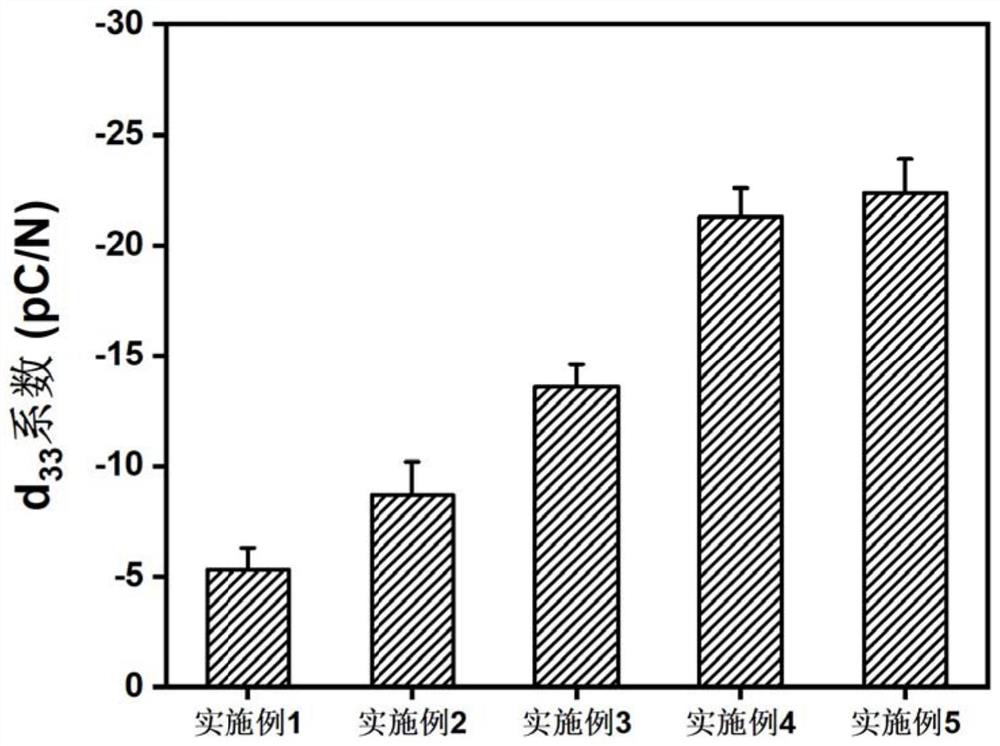

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com