Ultrasonic guided wave frequency dispersion curve calculation method

An ultrasonic guided wave and dispersion curve technology, applied in the field of ultrasonic guided wave dispersion curve calculation, can solve the problems of low calculation efficiency of solving dispersion curve and increased plate thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0058] Method example:

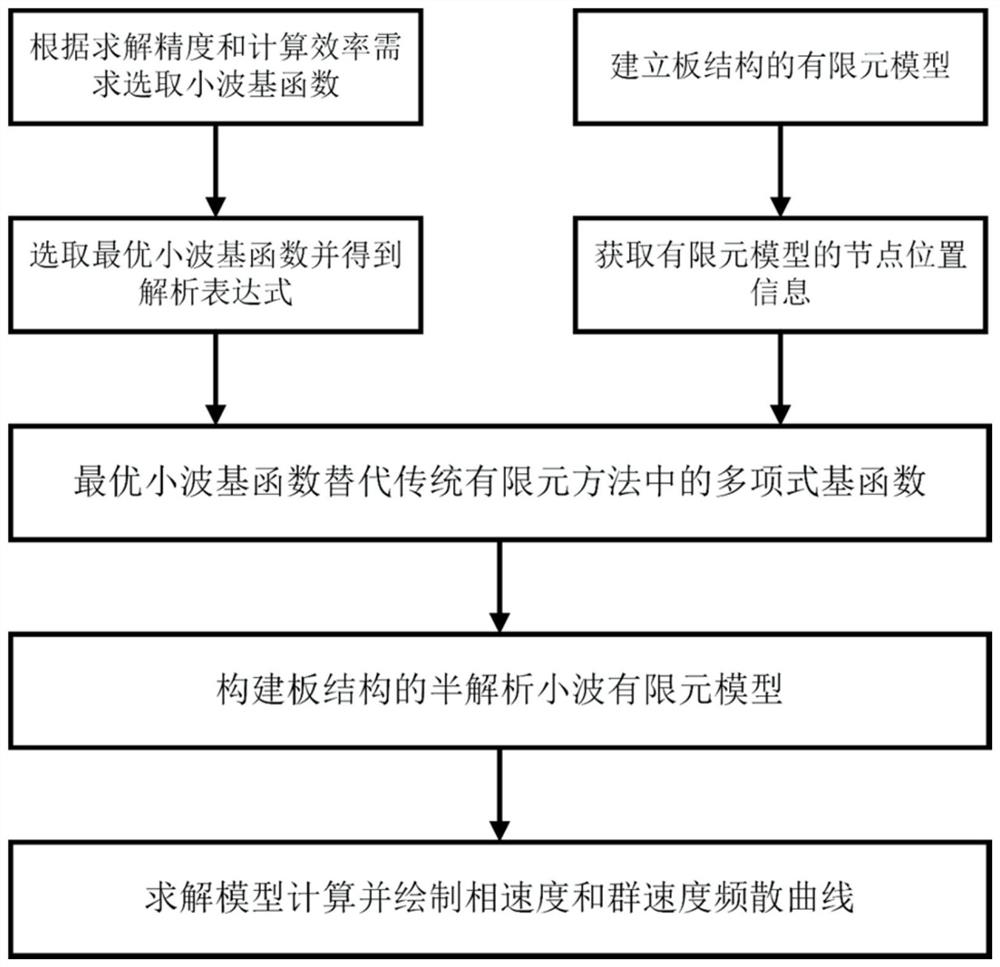

[0059] like figure 1 As shown, the ultrasonic guided wave dispersion curve calculation method of the present invention includes the following steps:

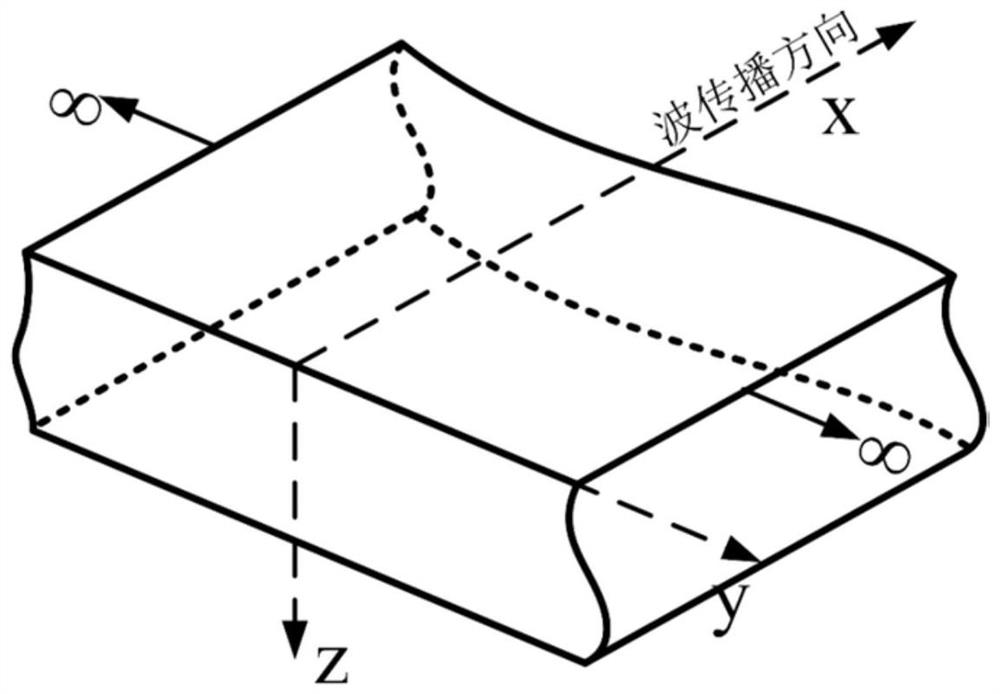

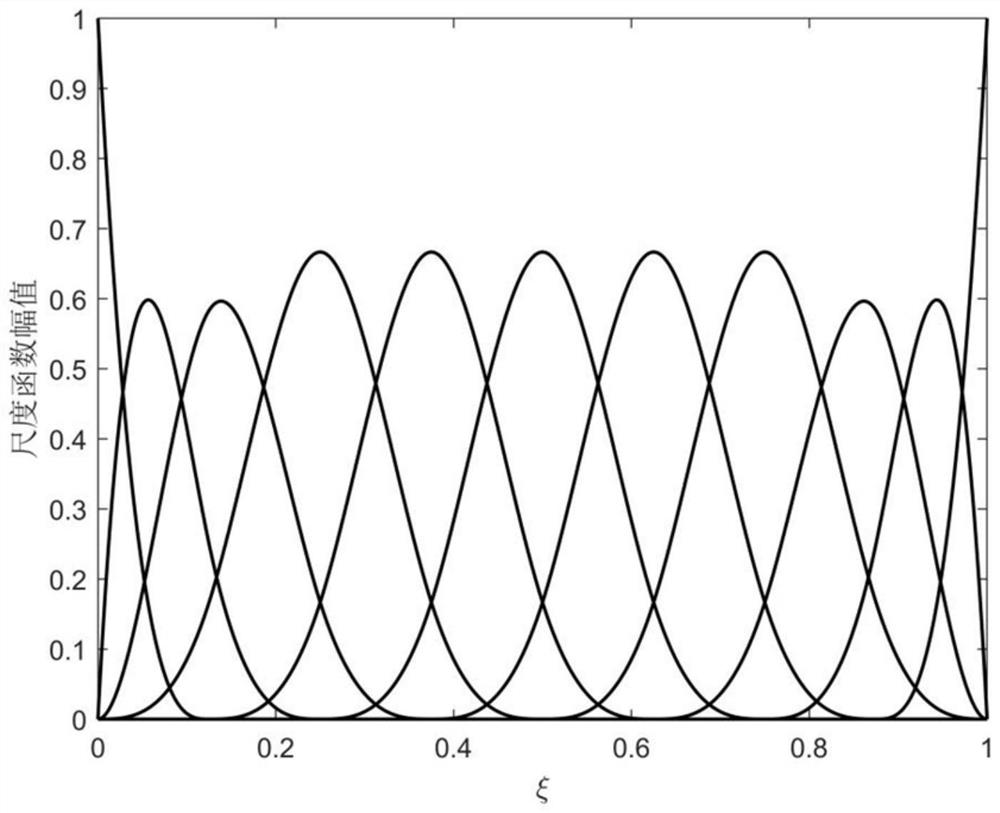

[0060] 1. Use the semi-analytical method to establish a finite element model of the plate structure to be tested. The size of the finite element model and the plate structure to be measured in the thickness direction is the same. At the same time, according to the requirement of solution accuracy, interval B-spline wavelet functions of different scales are selected, and the scale function of the interval B-spline wavelet unit and the unit transformation matrix of the one-dimensional interval B-spline wavelet unit are obtained. Using the scale function of the interval B-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com