Heterogeneous metal energy-absorbing and shock-absorbing high-damping component and additive manufacturing method thereof

A heterogeneous metal, high damping technology, applied in shock absorbers, additive manufacturing, additive processing, etc., can solve problems such as space extrusion, achieve shock absorption protection, and realize the effect of reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

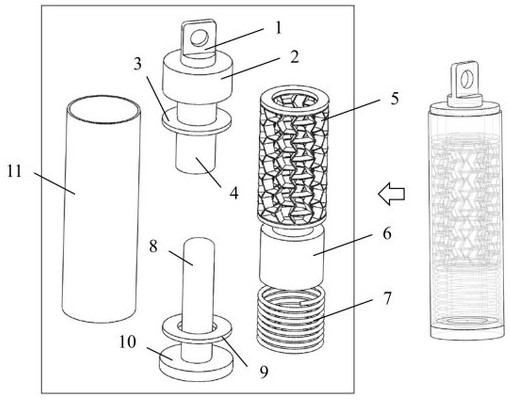

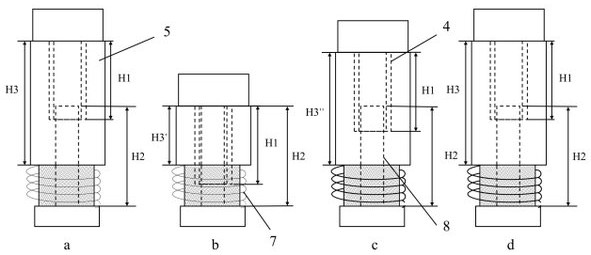

[0067] An additive manufacturing method for a heterogeneous metal energy-absorbing, shock-absorbing and high-damping component, comprising the following steps:

[0068] S1. Model processing: Use Solidworks to build the shape memory alloy shock absorber core 5 and the stabilizer 6 model, and import the built model into Magics for processing;

[0069] ①Build block support for the suspended surface in the model along the slope closest to the suspended surface;

[0070] ②Set the shape memory alloy shock absorbing core 5 as the processing material of NiTi alloy, and the processing parameters are: laser power (P) 105w, scanning speed (v) 600mm / s, scanning distance (h) 80μm, layer thickness 30μm;

[0071] ③Set the processing material of the stabilization table 6 to be Mn-Cu alloy, the processing parameters are: laser power 200w, scanning speed 400mm / s, laser scanning spacing 80μm, layer thickness 30μm;

[0072] ④ Set the intermediate layer to be Cu metal with a thickness of 0.8mm; ...

Embodiment 2

[0087] Embodiment 2: A method for additive manufacturing of heterogeneous metal energy-absorbing, shock-absorbing and high-damping components, comprising the following steps:

[0088] S1. Use Solidworks to build the shape memory alloy shock absorbing core 5 and the stabilizer 6 model, and import the built model into Magics for processing;

[0089] ①Build block support for the suspended surface in the model along the slope closest to the suspended surface;

[0090] ②Assign the processing parameters of the shape memory alloy shock absorption core 5 model: the laser power is 105w, the scanning speed is 600mm / s, the laser scanning distance is 80μm, and the layer thickness is 30μm;

[0091] ③Select the rotary scanning strategy, the rotation angle is 67°, and the strip width is 5mm;

[0092] S2. Select NiTi powder with a particle size of 15-53μm and a Ni composition of 50.8%at for processing preparation. The oxygen content in the forming chamber is controlled below 50ppm, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com