New energy automobile battery pack mounting bracket

A technology for installing brackets for new energy vehicles, which is applied to battery pack components, secondary batteries, circuits, etc., and can solve problems such as inability to protect the battery pack from vibration isolation, poor shock absorption protection performance, and poor heat dissipation performance of the bracket. Achieve the effects of improving work stability and work safety, improving use safety, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

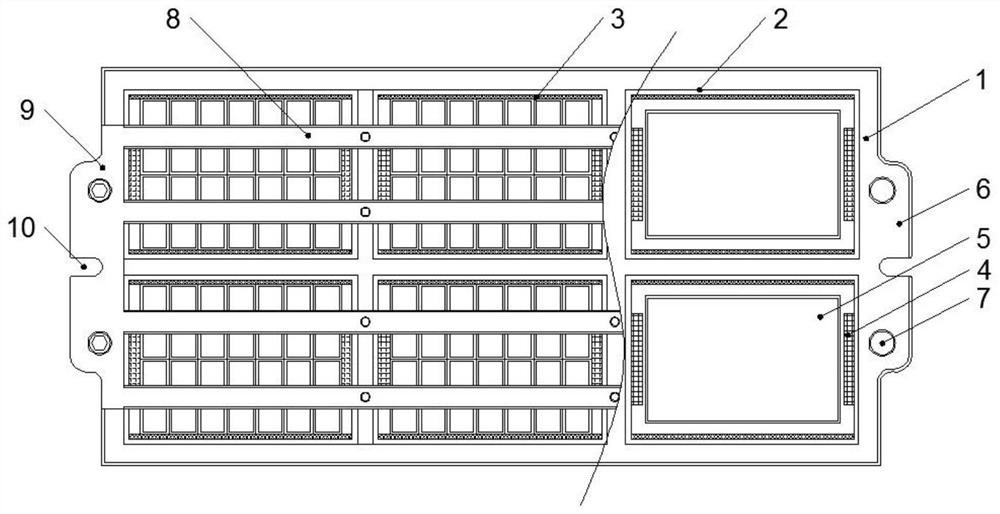

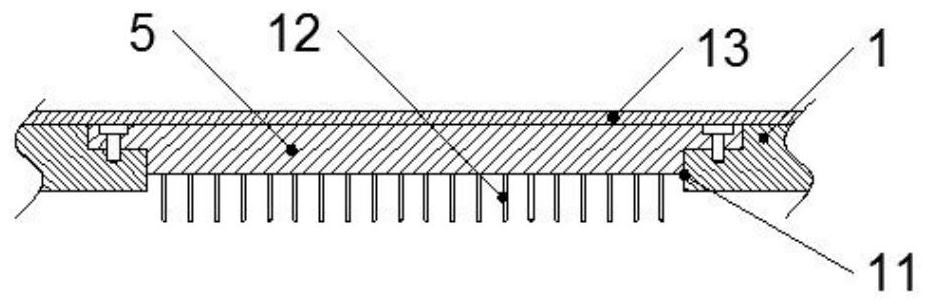

[0018] Example: such as Figure 1-2 As shown, a new energy vehicle battery pack installation bracket of the present invention includes a bracket body 1, a plurality of battery placement slots 2 are arranged on the top of the bracket body 1, and the front and rear sides of the battery placement slots 2 are fixed and glued. Connected with a rubber pad 3, the left and right sides of the battery storage tank 2 are fixedly equipped with power sockets 4, and the power sockets 4 are connected in series, and the bottom of the battery storage tank 2 is equipped with a groove 11, and the installation groove 11 runs through the bracket body 1, the heat absorption plate 5 is fixedly installed inside the installation groove 11, and a number of heat dissipation fins 12 are fixedly connected to the bottom side of the heat absorption plate 5, the The bracket body 1 is fixedly installed with a fixed gusset 8 near the top opening of the battery placement groove 2, and the fixed gusset 8 is fixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com