Method for manufacturing epitaxial silicon wafer

A manufacturing method, a technology of epitaxial silicon, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve the problem of quality degradation of epitaxial silicon wafers, and achieve the effect of reducing quality degradation

Pending Publication Date: 2022-07-22

SUMCO CORP

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The components from which the by-products are removed can be used for epitaxial growth again, but if the cleaning process and etching are repeated many times, the quality of the epitaxial silicon wafer will deteriorate, so the components need to be replaced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

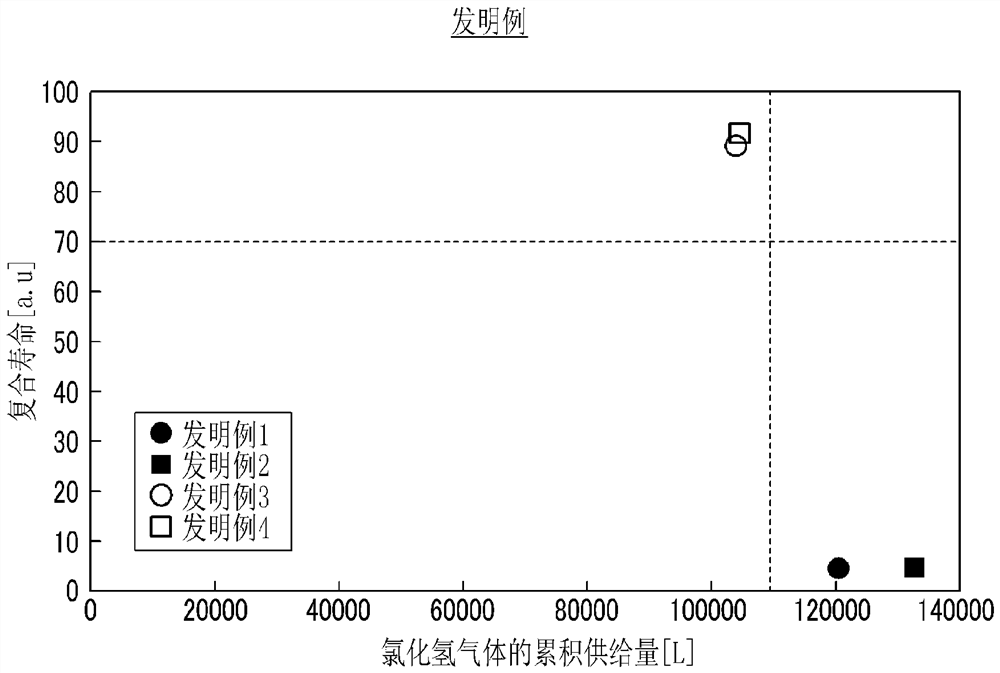

[0087] In order to confirm the effect of the present invention, use figure 1 , 2 In the epitaxial growth apparatus shown, Experiments 1 to 4 for sequentially producing silicon epitaxial wafers were performed. In addition, as a susceptor, a silicon carbide film (SiC: Vickers hardness of 2,346 kgf / mm) was used using graphite as a base material. 2 ) covering the surface of the base metal.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

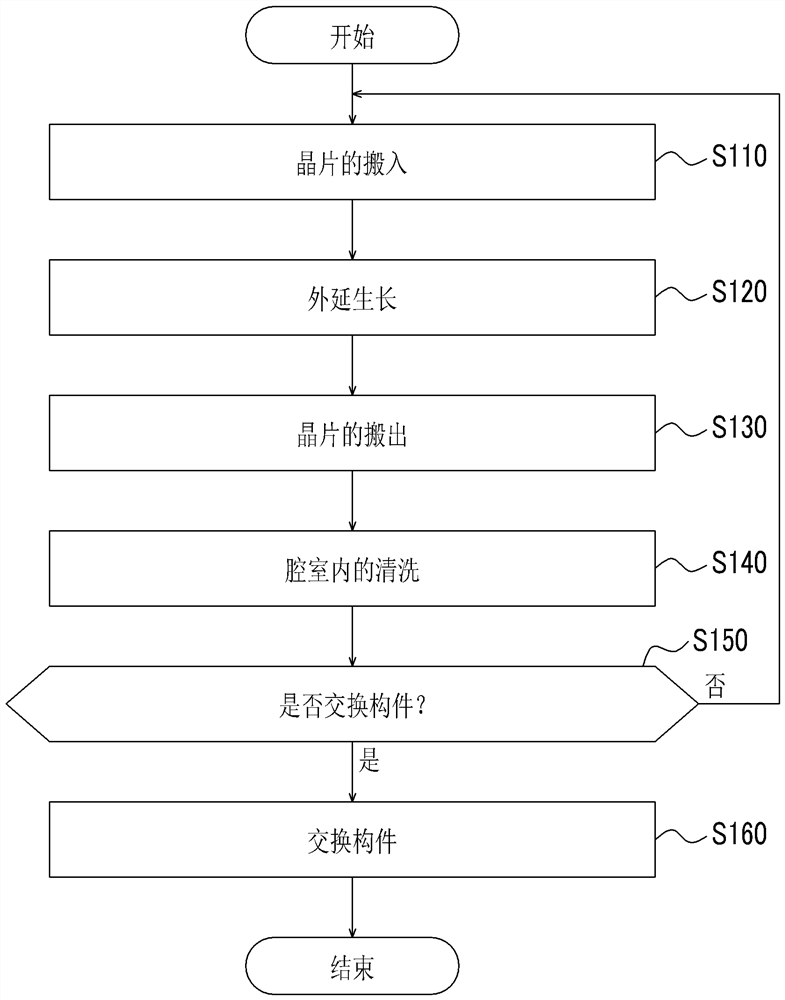

The method for manufacturing an epitaxial silicon wafer according to the present invention is a method for manufacturing an epitaxial silicon wafer by transferring a wafer into a chamber, epitaxially growing the wafer, transferring the wafer out of the chamber, and then cleaning the chamber with a hydrogen chloride gas, the method being characterized in that, after the cleaning, the hydrogen chloride gas is supplied in accordance with the cumulative supply amount of the hydrogen chloride gas, and the hydrogen chloride gas is supplied in accordance with the cumulative supply amount of the hydrogen chloride gas. It is determined whether or not to replace a member which is provided in a chamber and in which a graphite-containing base material is covered with a silicon carbide film.

Description

technical field [0001] The invention relates to a manufacturing method of an epitaxial silicon wafer. Background technique [0002] The epitaxial silicon wafers were sequentially produced by repeating the cycle by taking the wafer into the chamber of the epitaxial growth apparatus, the epitaxial growth, and the wafer unloading out of the chamber as one cycle. [0003] In the epitaxial growth, by-products generated from the source gas are deposited on the inner wall of the chamber and members provided in the chamber. If the above cycle is repeated in a state where the by-product is left, particles are generated from the by-product, and the quality of the epitaxial silicon wafer is adversely affected. Therefore, it is necessary to remove the by-products accumulated in the components in the chamber after repeating the above cycle a certain number of times. In order to remove the by-products, there is a method of heating the components in the chamber, and then performing a cle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/205C23C16/24C23C16/44

CPCC23C16/24H01L21/02381H01L21/0262H01L21/02532C23C16/0236C23C16/0218C23C16/4405C23C16/4404C23C16/4581C23C16/4585C23C16/46C30B29/06C30B25/02C30B25/14C30B25/12C30B25/10

Inventor 后藤志贵

Owner SUMCO CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com