Self-temperature-limiting electric tracing band with positive temperature coefficient and preparation method of self-temperature-limiting electric tracing band

A positive temperature coefficient, electric heating cable technology, applied in the direction of heating element shape, heating element material, etc., can solve the problems of inability to produce self-limiting electric heating cable, low conductive filler content, etc., to achieve excellent heating performance and high PTC strength. , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]At present, in the field of electric blankets that require extremely high flexibility and bending performance, it is still impossible to produce qualified self-limiting temperature electric heating cables. Therefore, how to effectively build a conductive network and form macroscopically uniform but localized electric heating cables during the processing of electric heating cables. The concentrated distribution of fillers has important practical application value for improving the processing fluidity, PTC strength and mechanical properties of the self-limiting temperature electric heating cable.

[0045] In view of the above problems, this embodiment provides a self-limiting temperature electric heating cable with a positive temperature coefficient, which adopts a single polymer material as the matrix and has a low content of conductive fillers, and has excellent processing fluidity, heat generation performance and mechanical performance. , can be widely used in tanks, pip...

Embodiment 2

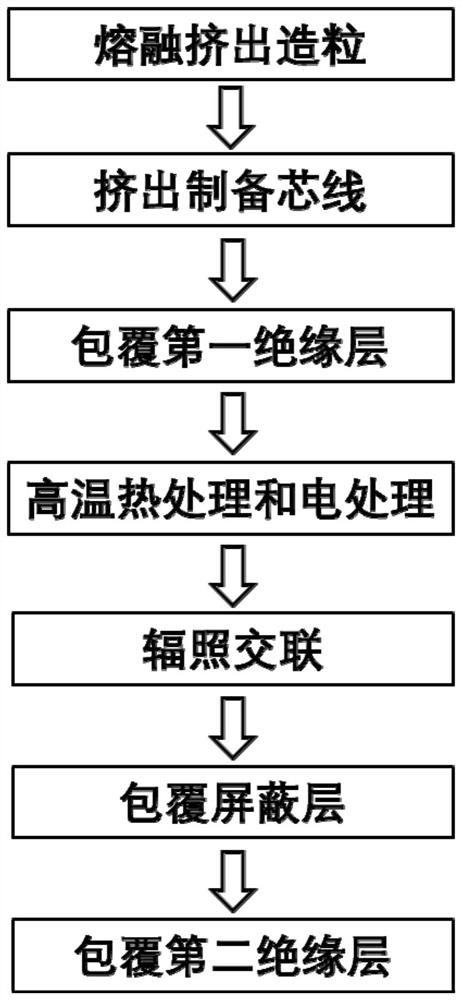

[0053] Embodiment 2 For the self-limiting temperature electric heating cable with a positive temperature coefficient in the first embodiment, a preparation method for a self-limiting temperature electric heating cable with a positive temperature coefficient is proposed, please refer to Figure 1-3 , including the following steps:

[0054] Step S1: The conductive filler, the radiation cross-linking sensitizer and the heating tape base material are mixed uniformly to form PTC conductive composite material particles; specifically, the detailed steps of the step S1 are: After mixing the sensitizer and the heating tape base material evenly, the twin-screw extruder is melted, extruded and granulated to obtain PTC conductive composite material particles; preferably, the extrusion temperature of the twin-screw extruder is 160°C- 230℃;

[0055] In this embodiment, specifically, the mass percentage content of the conductive filler in the step S1 is 5-15%, the mass percentage content of...

Embodiment 3

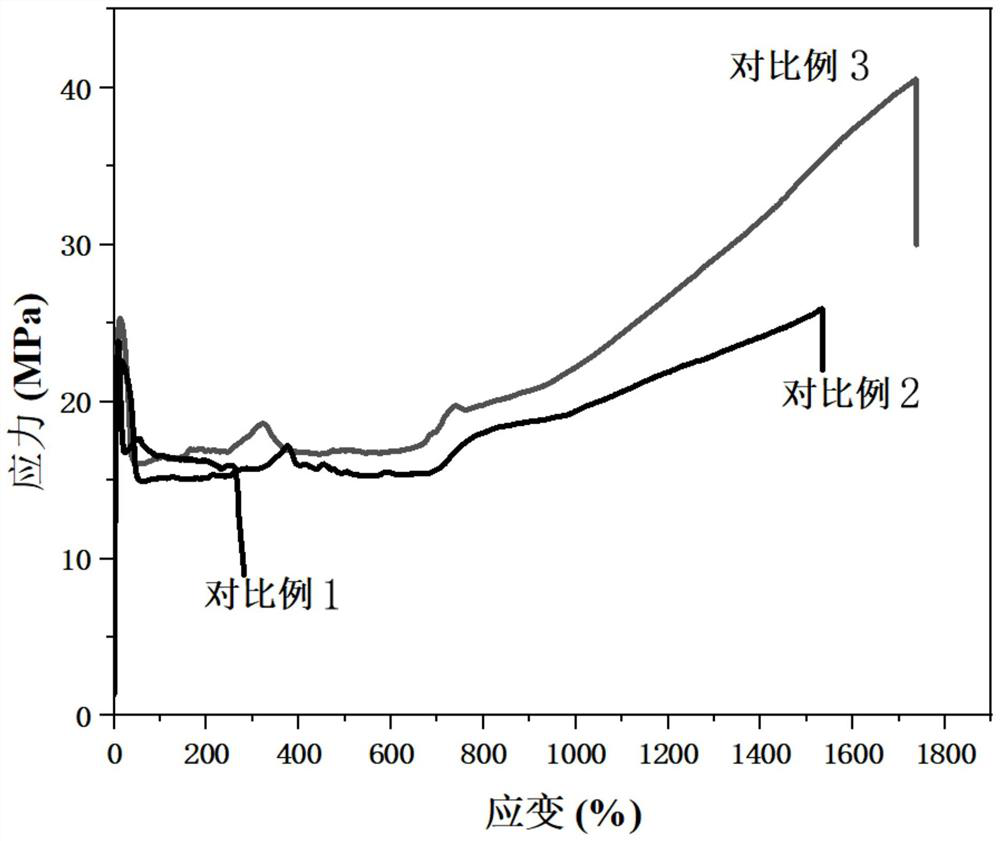

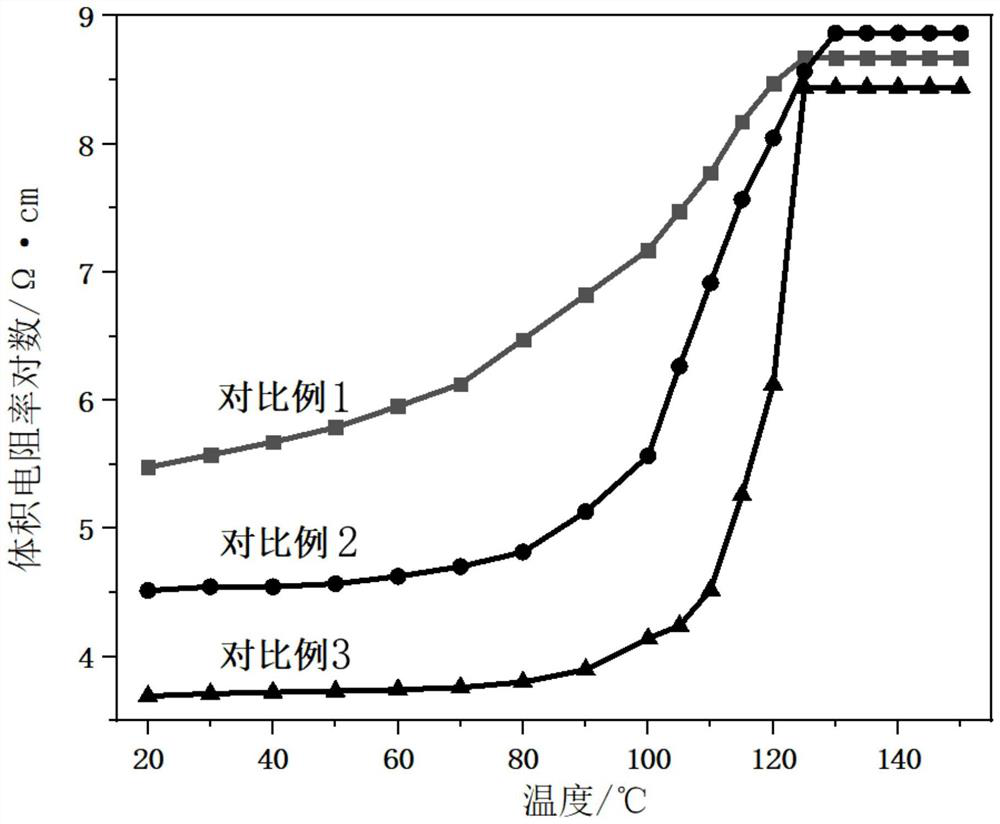

[0068] In the third embodiment, three groups of experimental parameters and realization data are given to further illustrate the advantages of the electric heating cable in the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com