Volume Bragg grating wavelength beam combiner based on photo-thermal refractive glass and preparation method thereof

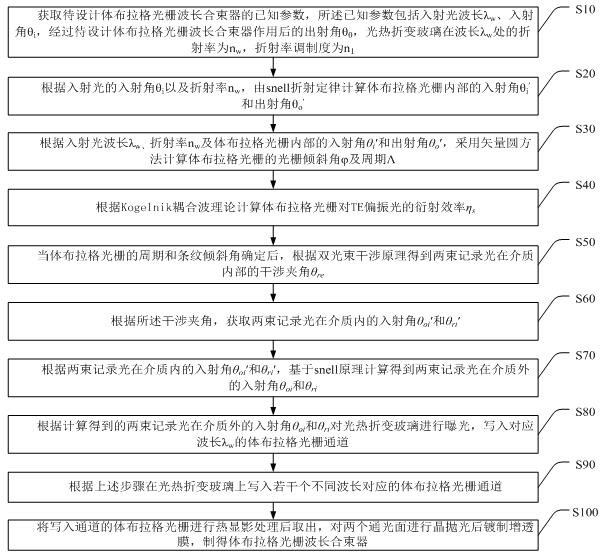

A volume Bragg grating and beam combiner technology, applied in diffraction grating and other directions, can solve the problems of poor environmental adaptability of wavelength beam combiner, poor anti-laser damage ability, complex preparation process, etc. , the effect of simple process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

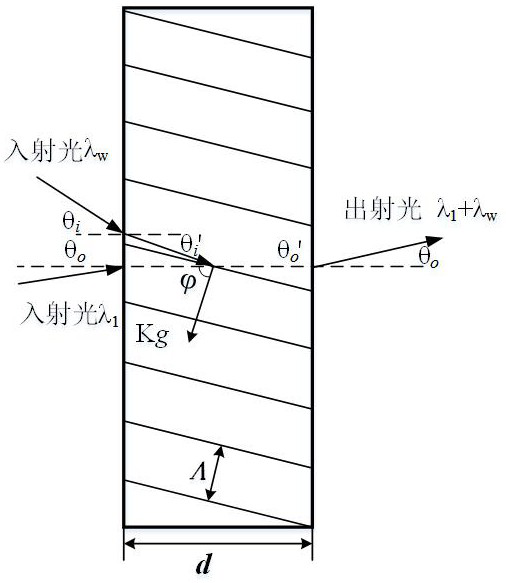

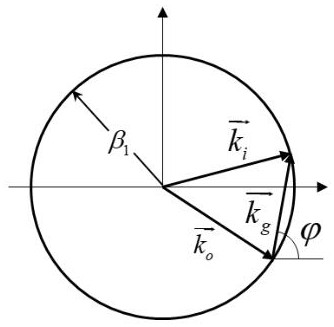

[0066] Provided is a preparation method of a volume Bragg grating beam combiner based on photothermal refractive glass, which realizes beam grouping of three wavelengths of 450 nm, 532 nm and 640 nm, and the polarization state of the three-wavelength light is TE polarization. Figure 5 It is a schematic diagram of the structure and use optical path of the three-wavelength beam combiner. Considering the compactness of the system (the incident angle should not be too large), the light with a wavelength of 450nm is incident into the beam combiner at 0° and exits at 0° without occupying the grating channel. The light with wavelengths of 532nm and 640nm is incident into the beam combiner at 10° and exits at 0°. By definition, the angle of incidence for 532nm light is 10°, and the angle of incidence for 640nm light is -10°. Take the grating thickness d as 1mm and the diffraction efficiency as 100%.

[0067] 1. According to the description of the above application indicators, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com