Wall thickness detection device based on spheroidal graphite cast pipe

A technology for detecting devices and cast pipes, applied in measuring devices, instruments, using ultrasonic/sonic waves/infrasonic waves, etc., can solve the problems of unguaranteed, detection signal interference, measurement signal loss, etc., achieve constant distance, reduce measurement noise, The effect of saving coupling agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further explained below with reference to the accompanying drawings.

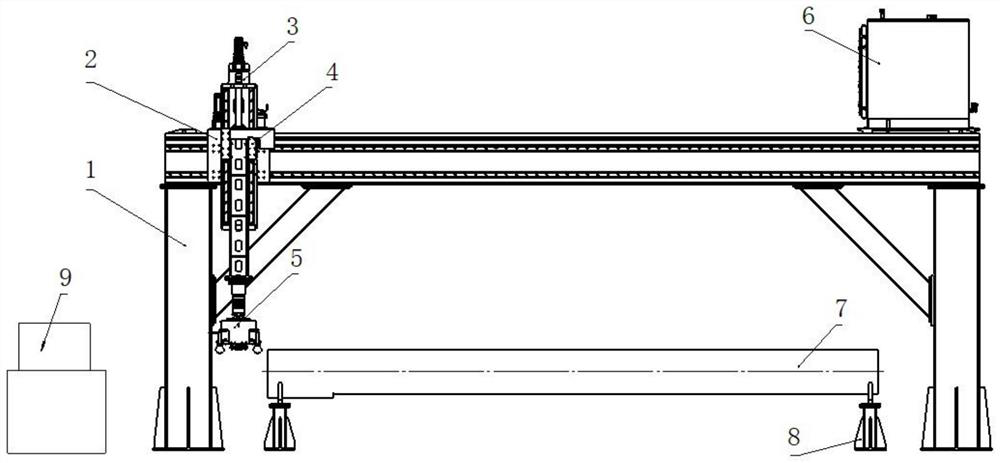

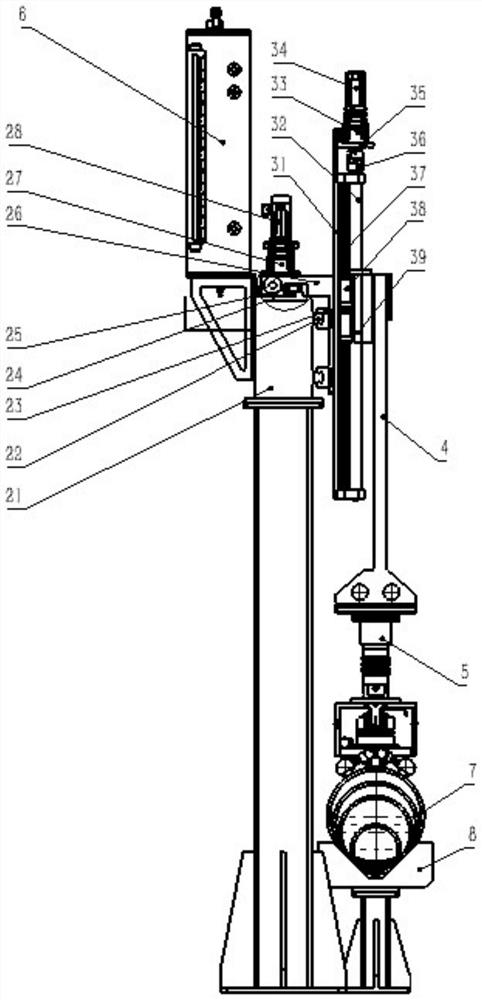

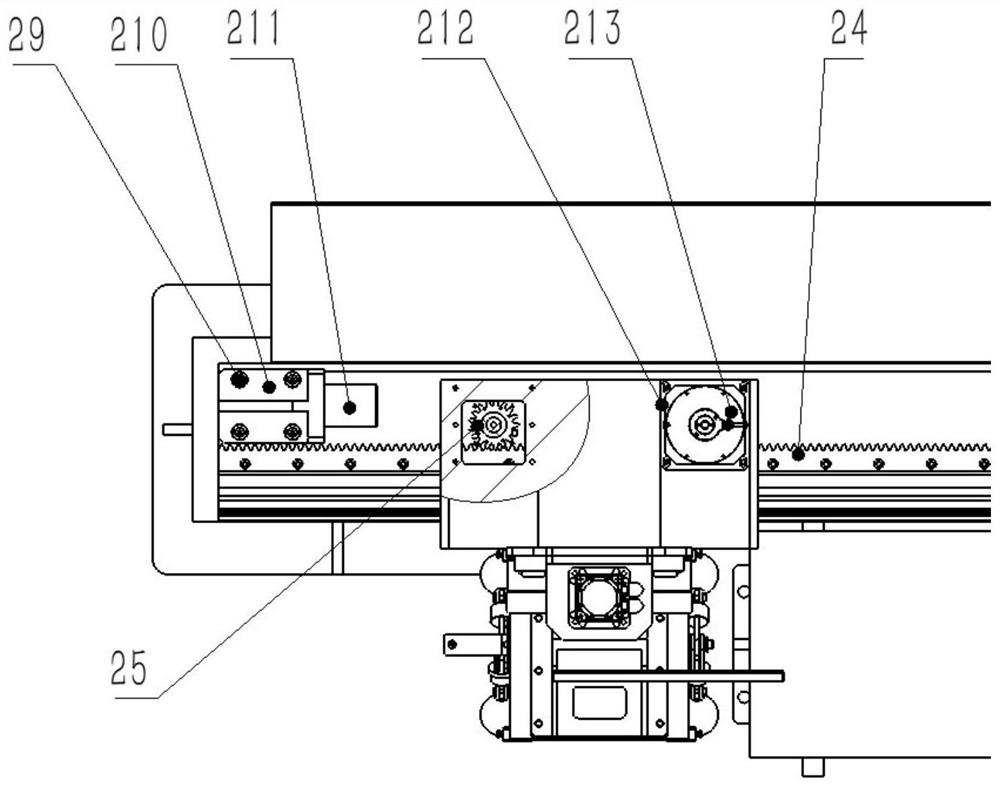

[0026] like Figure 1-2 , The present invention provides a wall thickness detection device based on a ductile cast tube, comprising: a frame 1, an X-axis mechanism 2, a Y-axis mechanism 3, a trolley mounting frame 4, a four-wheel passive trolley 5, a thickness gauge water tank 6, In the control system 9, the four-wheel passive trolley 5 has a long stroke in the X-axis direction, and the positional accuracy requirements are relatively low. Therefore, the X-axis mechanism 2 in the present invention is a rack-and-pinion transmission mechanism, and the X-axis mechanism 2 is horizontally arranged on the frame 1. , In the Y-axis direction, it is necessary to control the distance from the four-wheel passive trolley 5 to the pipe surface of the ductile cast tube 7, which requires high precision and short stroke. Therefore, the Y-axis mechanism 3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com