Cooling device for lean absorption liquid in ethylene oxide production system

A production system, ethylene oxide technology, applied in lighting and heating equipment, indirect heat exchangers, fixed tubular conduit assemblies, etc., can solve problems such as low temperature, and achieve the effect of good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The embodiment of the present application discloses a cooling device for lean absorbing liquid in an ethylene oxide production system. Since the structure of the cooling device in the following embodiments is exactly the same, the difference lies in whether sufficient coating is applied and the composition of the anti-scaling coating , the ratio. Therefore, taking Example 1 as an example, the structure of the cooling device for the lean absorbing liquid in the ethylene oxide production system will be described.

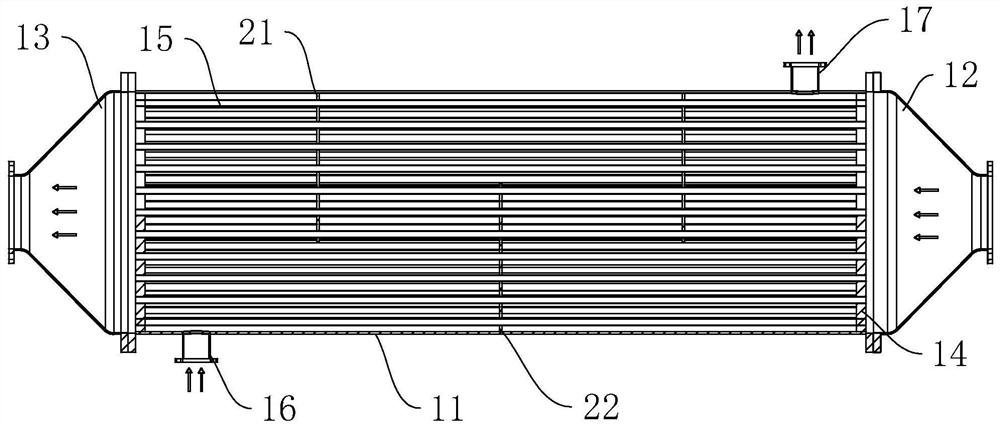

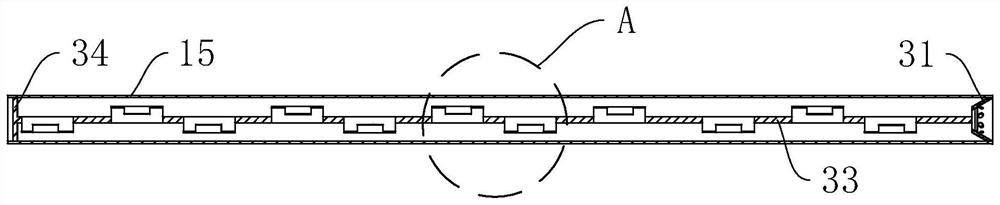

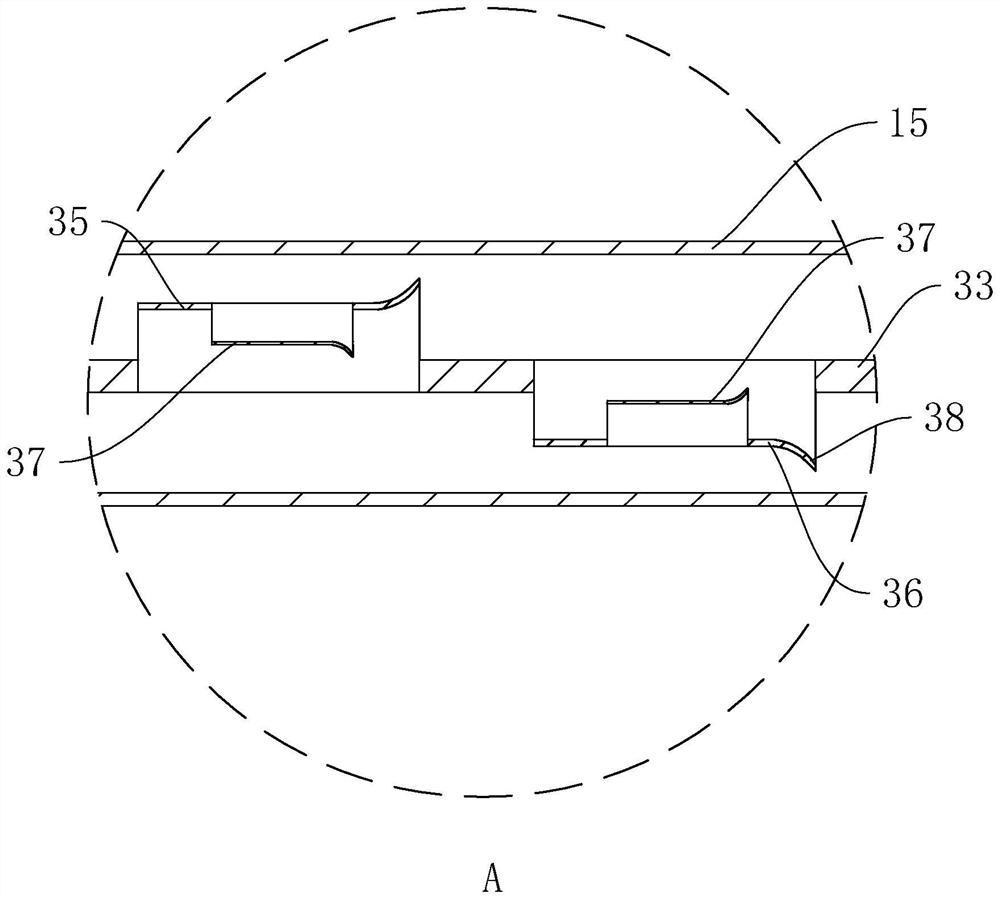

[0058] refer to figure 1 , a cooling device for lean absorbing liquid in an ethylene oxide production system, comprising a shell 11, a liquid inlet tank 12, a liquid outlet tank 13, a tube sheet 14, a heat exchange tube 15, a refrigerant inlet pipe 16 and a refrigerant outlet pipe 17 . The shell 11 is hollow cylindrical, and the liquid inlet tank 12 and the liquid outlet tank 13 are fixedly connected to two ends of the shell 11 respectively.

[0059] refer t...

Embodiment 2

[0068] The difference between Example 2 and Example 1 is that the turbulent flow structure and the inner wall of the heat exchange tube 15 are all coated with scale-inhibiting paint, and each compounded scale-inhibiting paint includes the following raw materials by mass:

[0069]

[0070]

[0071] The above scale-inhibiting paint is compounded and blended, and then sprayed, and the thickness of the scale-inhibiting paint is controlled at 100 μm.

[0072] Among them, the epoxy resin is Phoenix brand water-based epoxy emulsion, the brand is 0947A-53W; the supporting curing agent is Phoenix brand water-based epoxy curing agent, the brand is 0947B-100W.

[0073] Among them, zinc phosphate, tannic acid, and p-cresol are all commercially available.

[0074] Wherein, the graphene loaded with polyaniline is prepared by the following process:

[0075] A1. Disperse graphene oxide. Disperse 0.5 g of commercially available graphene oxide in 1 L of water, and ultrasonicate for 1 h a...

Embodiment 3-6

[0085] The difference between Examples 3-6 and Example 2 is that the raw materials required for each compounded scale inhibitor coating are different, which are recorded as the following table:

[0086]

[0087]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com