Ammonia absorption type refrigeration device for treating emptying tail gas of chemical device and recycling waste heat and recycling method

A technology for exhaust gas treatment and waste heat recovery, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of insufficient utilization of heat and low-temperature ammonia cooling capacity, bulky heat exchange equipment, and high investment costs. Suitable for popularization, wide applicability, and the effect of improving the cooling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

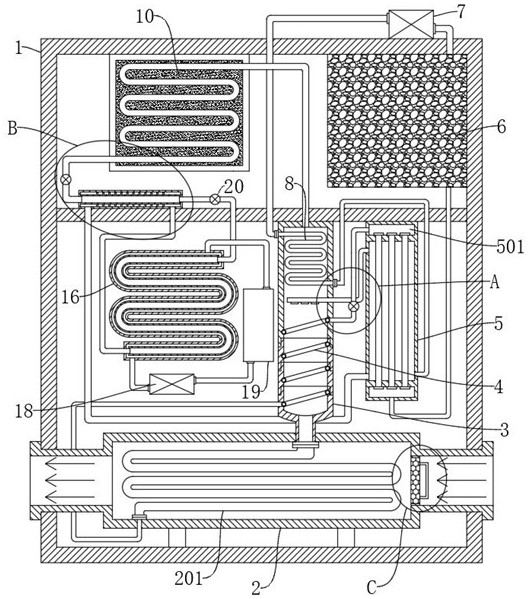

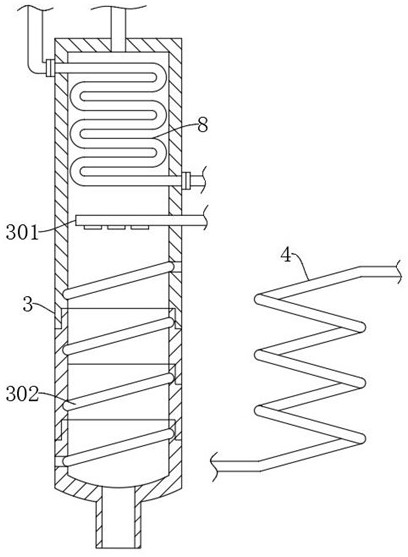

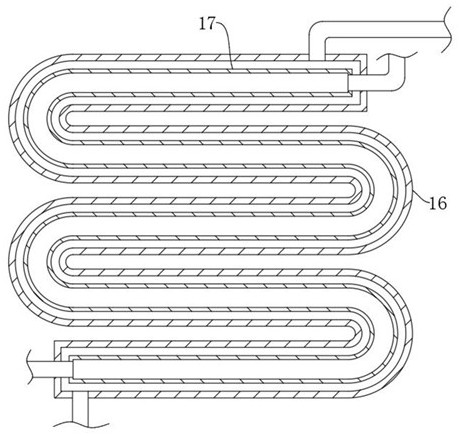

[0033] refer to Figure 1-Figure 6, a chemical plant venting tail gas treatment waste heat recovery ammonia absorption refrigeration device, including a chassis 1, also includes: a waste heat generator 2 with a solution pipe 201 inside, installed in the chassis 1; a stripper 3, installed in the waste heat generator 2 The regenerator 4 is arranged in the stripper 3, and the input end is connected to the liquid outlet of the solution pipe 201 in the waste heat generator 2; the solution throttle valve 11, the input end is connected to the output of the regenerator 4 end connection; heat exchanger 5, the input end of the internal pipeline is connected to the output end of the solution throttle valve 11; absorber 6, the input end is connected to the output end of the internal pipeline of the heat exchanger 5; solution pump 7, the input end is connected to the absorption The output end of the rectifier 6 is connected; the input end of the rectifier 8 is connected to the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com