Plug nozzle engine with secondary flow injection structure

A plug-type nozzle and secondary flow technology, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problem of not being suitable for using plug-type nozzles, etc. The effect of the amount of medicine and the increase of the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

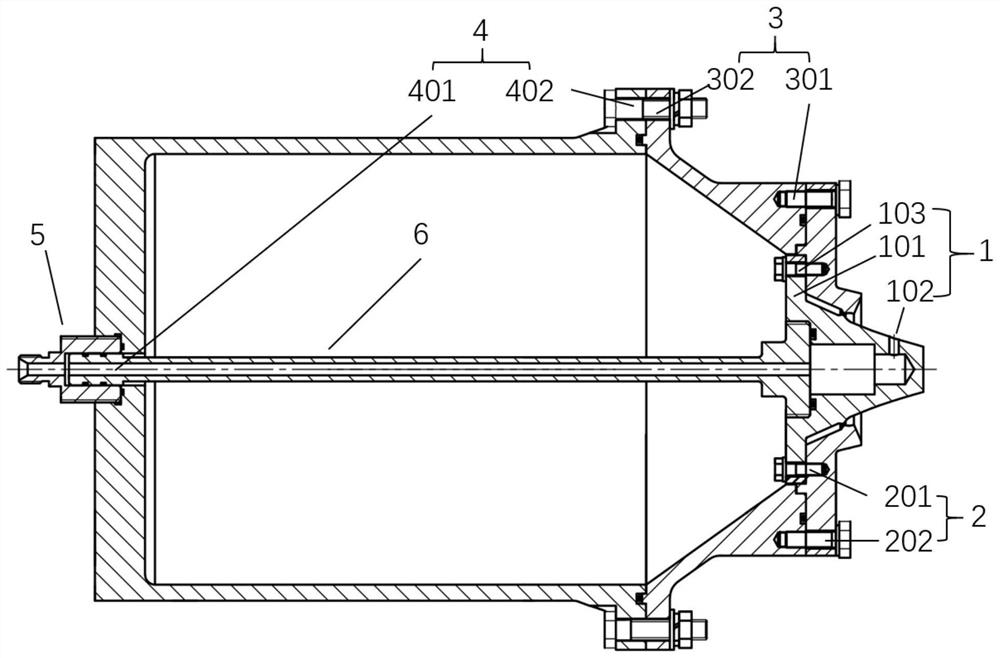

[0038] like figure 1 As shown, a plug nozzle engine with a secondary flow injection structure disclosed in this embodiment consists of a plug cone 1, an annular cover 2, a front end 3 of the combustion chamber, a rear end 4 of the combustion chamber, a connector 5 and two The secondary flow guide rod 6 is formed.

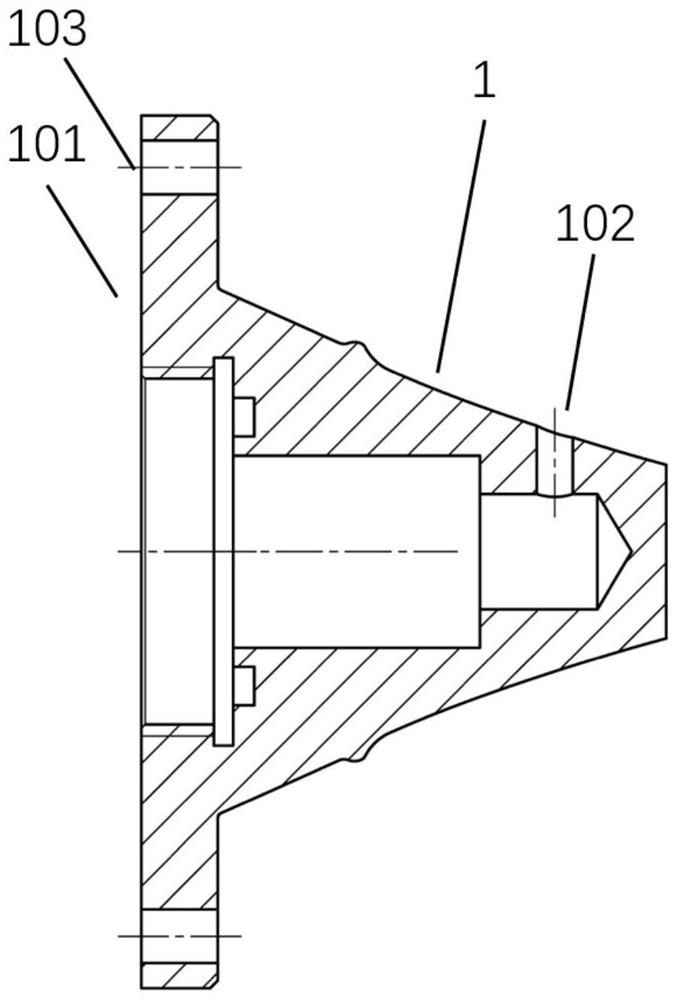

[0039] like figure 2As shown, the plug cone 1 includes a rib column 101 , a plug cone hole 102 and a rib column opening 103 .

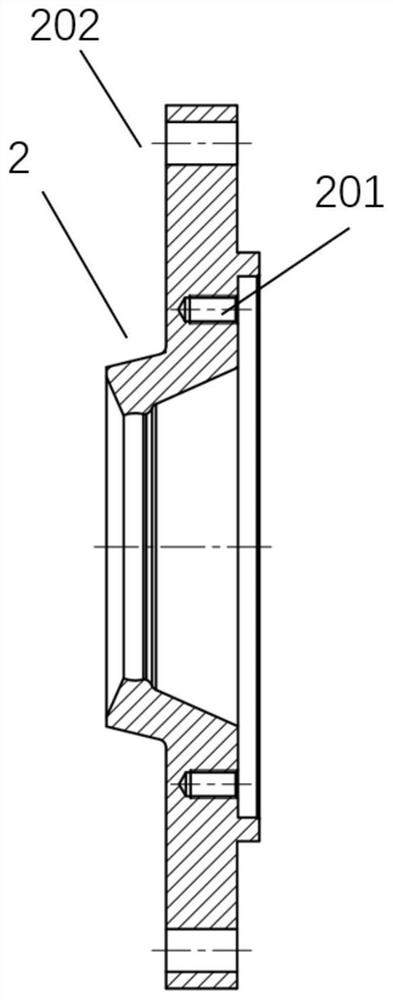

[0040] like image 3 As shown, the annular cover 2 includes a threaded hole 201 and a through hole 202 .

[0041] like Figure 4 As shown, the front end 3 of the combustion chamber includes a threaded opening 301 and a through hole 302 .

[0042] like Figure 5 As shown, the rear end 4 of the combustion chamber includes a bottom opening 401 and a through hole 402 .

[0043] Use 4 studs to pass through the openings 103 of the 4 rib columns 101 of the plug cone respectively, and fix them on the annular cover 2 through the threaded hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com