Partition wallboard base

A technology of wall panels and side panels, applied in the field of partition wall panel bases, can solve the problems of reduced support and fixing effect of partition wall panels, complex base structure, reduced tank stability, etc. Integrity and use stability assurance, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

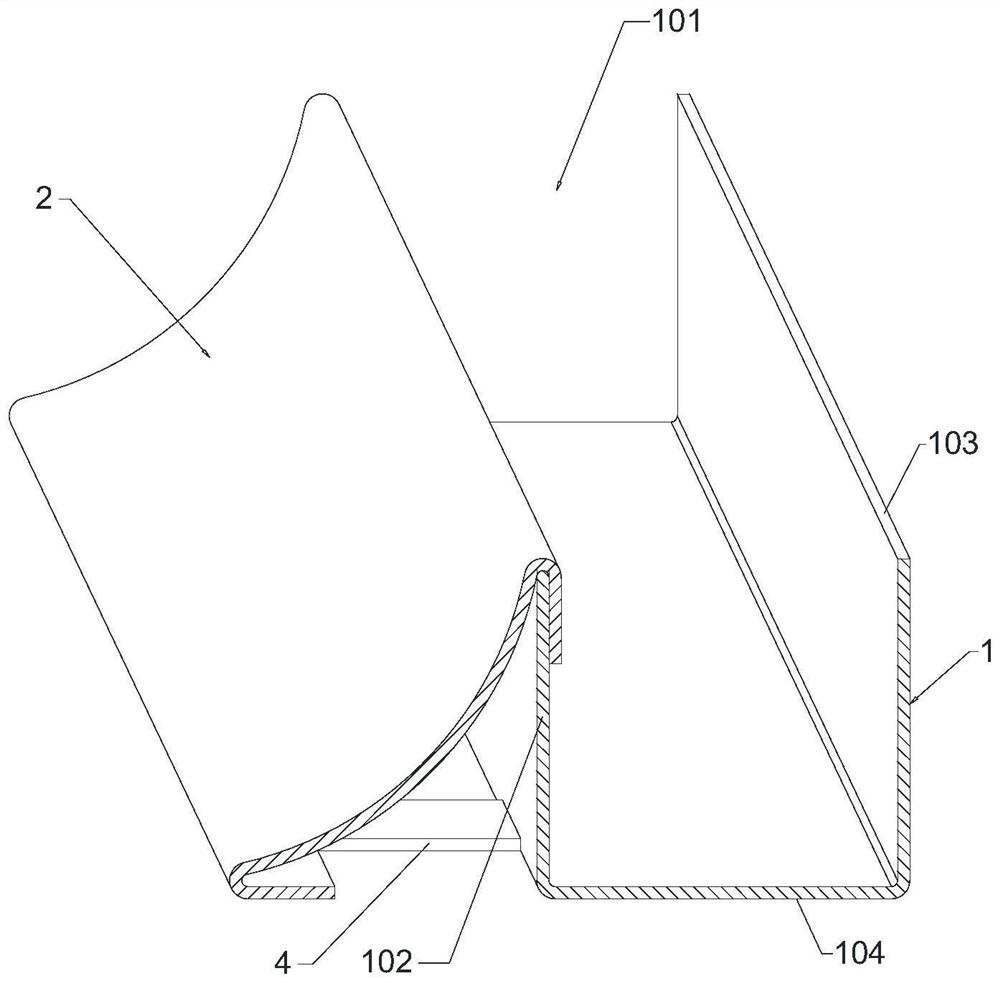

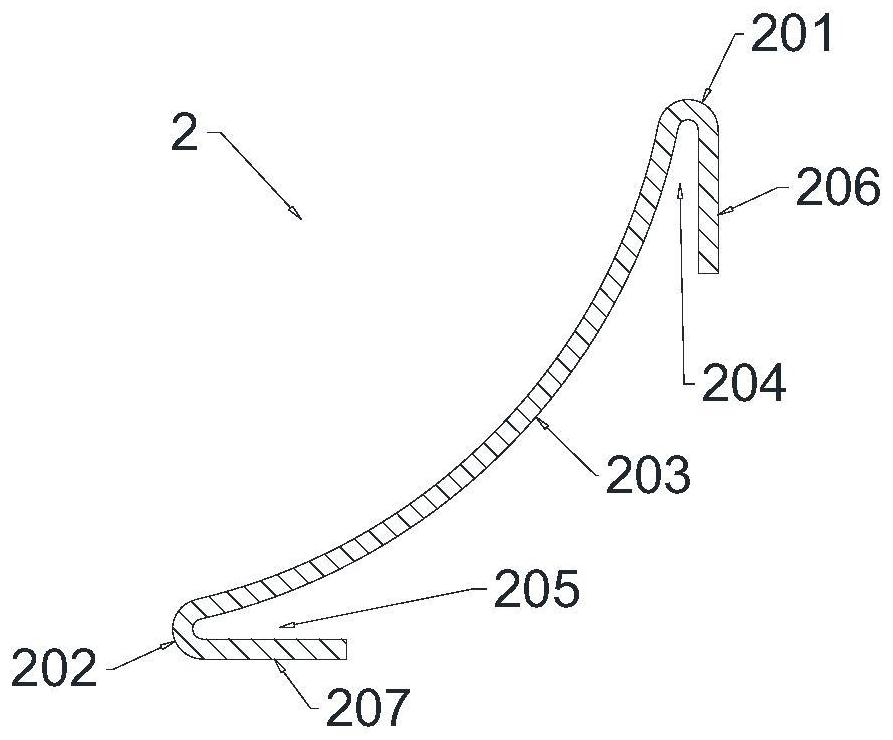

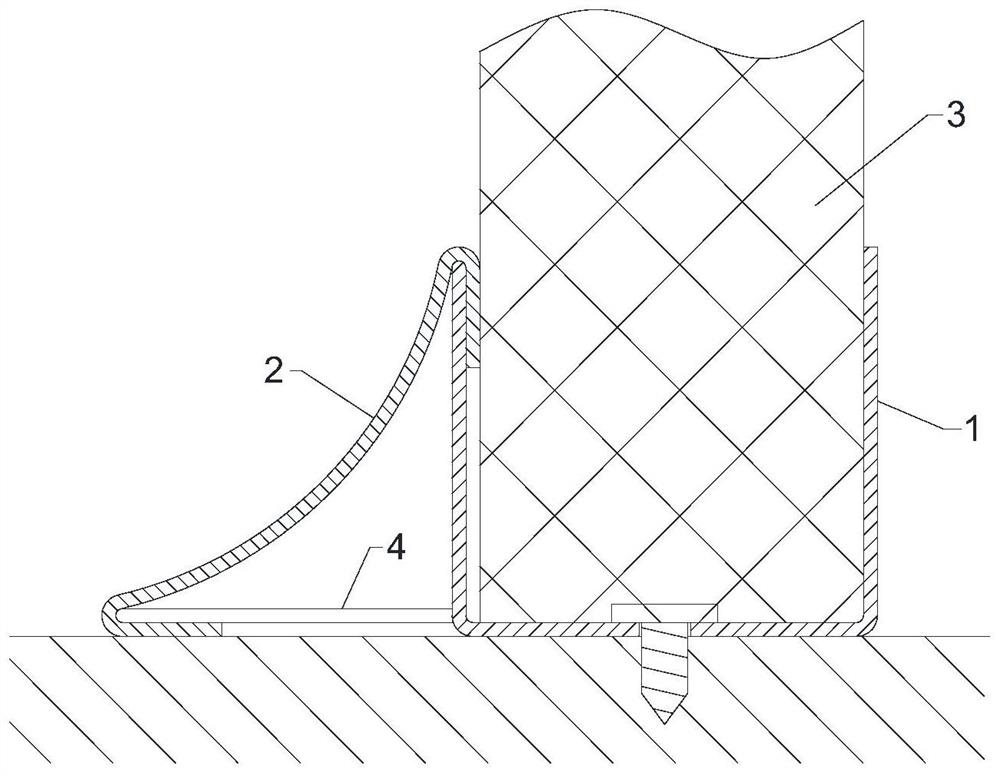

[0032] like Figures 1~6 The base of the partition wall panel shown is preferably made of corrosion-resistant, high-strength metal materials such as stainless steel. It includes a U-shaped groove body 1 that opens upward and a first transition plate 2 connected to one side of the groove body 1. The U-shaped groove 101 at the upper end of the groove body 1 is used for inserting the wall plate 3, and both sides of the U-shaped groove 101 are used. They are the first side plate 102 and the second side plate 103 of the tank body 1 respectively. The bottom of the U-shaped groove 101 is the bottom plate 104 connecting the first side plate 102 and the second side plate 103. The first transition plate 2 is obliquely arranged in the groove. The outer side of the body 1 is used to connect the first side plate 102 of the tank body 1 and the ground. like figure 2 As shown, the upper part of the first transition plate 2 is bent toward its back along a bending line parallel to the axial ...

Embodiment 2

[0046] like Figure 7 and Figure 8 As shown, the partition wall panel base shown in this embodiment includes a U-shaped groove body 1 opening upward and a first transition plate 2 connected to one side of the groove body 1. The U-shaped groove 101 at the upper end of the groove body 1 is used for In the plug-in wall panel 3, the two sides of the U-shaped groove 101 are the first side plate 102 and the second side plate 103 of the tank body 1 respectively, and the bottom of the U-shaped groove 101 is the connection between the first side plate 102 and the second side plate 103. The bottom plate 104, the first transition plate 2 is obliquely arranged on the outside of the tank body 1, and is used to connect the first side plate 102 of the tank body 1 and the ground. The upper part of the first transition plate 2 is bent toward its back along a bending line parallel to the axial direction of the groove body to form an arc-shaped first upper bending part 201 and a straight first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com