Quick-positioning low-shrinkage UV moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and dual-cure technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor wettability of substrates and poor flexibility of products, and achieve good flexibility , Improving impact resistance, high degree of molecular adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

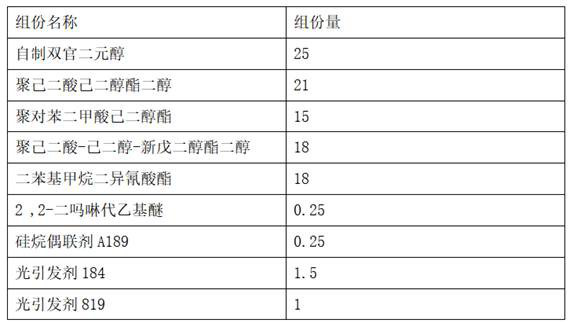

[0047] A fast-positioning low-shrinkage UV moisture dual-curing polyurethane hot-melt adhesive, comprising the following raw materials:

[0048]

[0049] In the present embodiment, the described preparation method is as follows:

[0050](1) 25 parts of self-made difunctional diols, 21 parts of polyethylene adipate, 15 parts of polyethylene terephthalate, and two parts of polyadipate-hexanediol-neopentyl glycol 18 parts of alcohol, mixed evenly, vacuumed and dehydrated at 120-125 ℃ for 2 hours, the vacuum degree is guaranteed to be ≤-0.098MPa, and the measured water content is ≤100ppm, and the next step is carried out.

[0051] (2) The mixed polyol was cooled to 80-85°C, 18 parts of diphenylmethane diisocyanate were added, the temperature was naturally raised for 15min, the temperature was maintained at 110-115°C, and the reaction was carried out under nitrogen protection for 60min.

[0052] (3) Keep at 110-115 ℃, add 0.25 parts of 2,2-dimorpholinoethyl ether, 0.25 parts of...

Embodiment 2

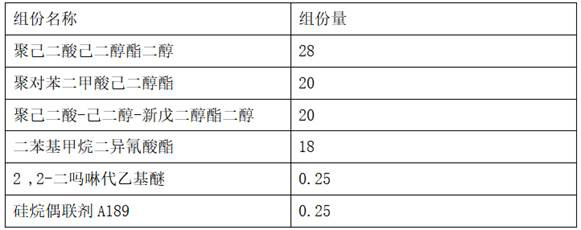

[0055] A fast-positioning low-shrinkage UV moisture dual-curing polyurethane hot-melt adhesive, comprising the following raw materials:

[0056]

[0057] In the present embodiment, the described preparation method is as follows:

[0058] (1) 35 parts of self-made difunctional diols, 21 parts of polyethylene adipate, 10 parts of polyethylene terephthalate, and two parts of polyadipate-hexanediol-neopentyl glycol 13 parts of alcohol, mixed evenly, vacuumed and dehydrated at 120-125°C for 2 hours, the vacuum degree was guaranteed to be ≤-0.098MPa, and the measured water content was ≤100ppm for the next step.

[0059] (2) The mixed polyol was cooled to 80-85°C, 18 parts of diphenylmethane diisocyanate were added, the temperature was naturally raised for 15min, the temperature was maintained at 110-115°C, and the reaction was carried out under nitrogen protection for 60min.

[0060] (3) Keep at 110-115 ℃, add 0.25 parts of 2,2-dimorpholinoethyl ether, 0.25 parts of silane coupl...

Embodiment 3

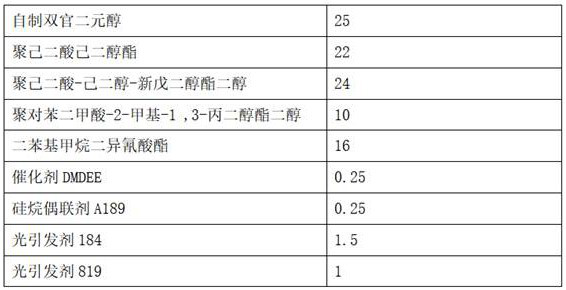

[0063] A fast-positioning low-shrinkage UV moisture dual-curing polyurethane hot-melt adhesive, comprising the following raw materials:

[0064]

[0065] In the present embodiment, the described preparation method is as follows:

[0066] (1) 25 parts of self-made difunctional diols, 22 parts of polyhexanediol adipate, 24 parts of polyadipate-hexanediol-neopentyl glycol ester diol, poly-2-terephthalate 10 parts of methyl-1,3-propanediol ester glycol, mixed evenly, vacuum dehydration at 120-125 ℃ for 2 hours, the vacuum degree is guaranteed to be ≤-0.098MPa, and the measured water content is ≤100ppm, and the next step is performed.

[0067] (2) Cool the mixed polyol to 80-85°C, add 16 parts of diphenylmethane diisocyanate, naturally heat up for 15min, keep at 110-115°C, and react under nitrogen protection for 60min.

[0068] (3) Keep at 110-115 ℃, add 0.25 parts of 2,2-dimorpholinoethyl ether, 0.25 parts of silane coupling agent A189, 1.5 parts of photoinitiator 184, 1 part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com