Antibacterial environment-friendly food packaging box and preparation process thereof

A food packaging box and preparation process technology, applied in the field of food packaging production, can solve problems such as affecting the quality of packaging boxes, affecting food safety, accumulating dust, etc., and achieving the effects of extending effective storage time, efficient antibacterial performance, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

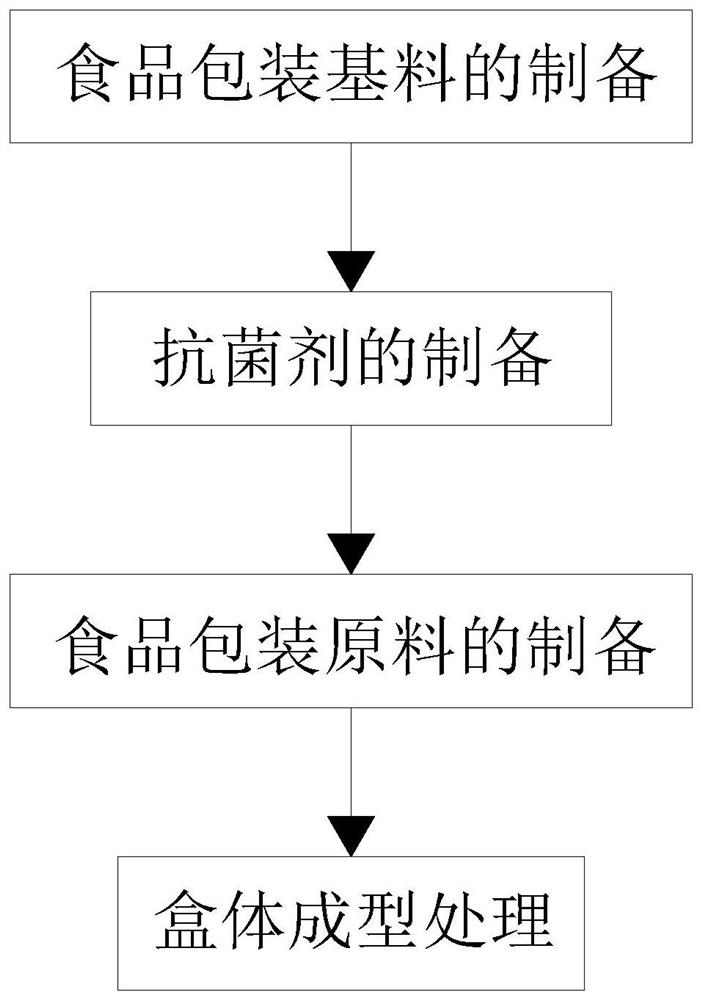

[0043] First, as Figure 1-12 As shown, the present invention provides a preparation process of an antibacterial and environmentally friendly food packaging box, and the preparation process of the antibacterial and environmentally friendly food packaging box comprises the following steps:

[0044] S1. Preparation of food packaging base material: first add polypropylene particles into the cleaning device for cleaning treatment, after cleaning, 46w% of polypropylene particles, 22w% of natural resin glue, 10w% of straw powder, and 7w of light calcium carbonate powder %, glycerol 4w%, anhydrous ethanol 8w% and pentaerythritol stearate 3w% were sequentially added to the high-temperature mixing furnace, then the heating rate of the high-temperature mixing furnace was controlled to be 5°C per minute, and it was stopped after heating to 95°C, And keep it for 2h, after it is cooled to room temperature, the food packaging base material is obtained;

[0045] S2, the preparation of antib...

Embodiment 2

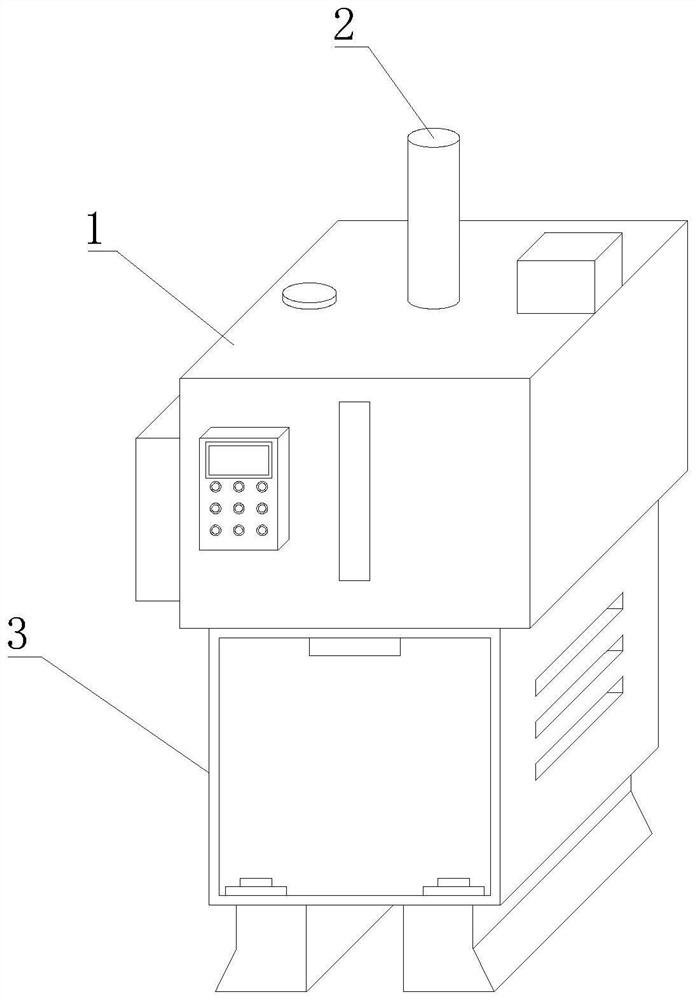

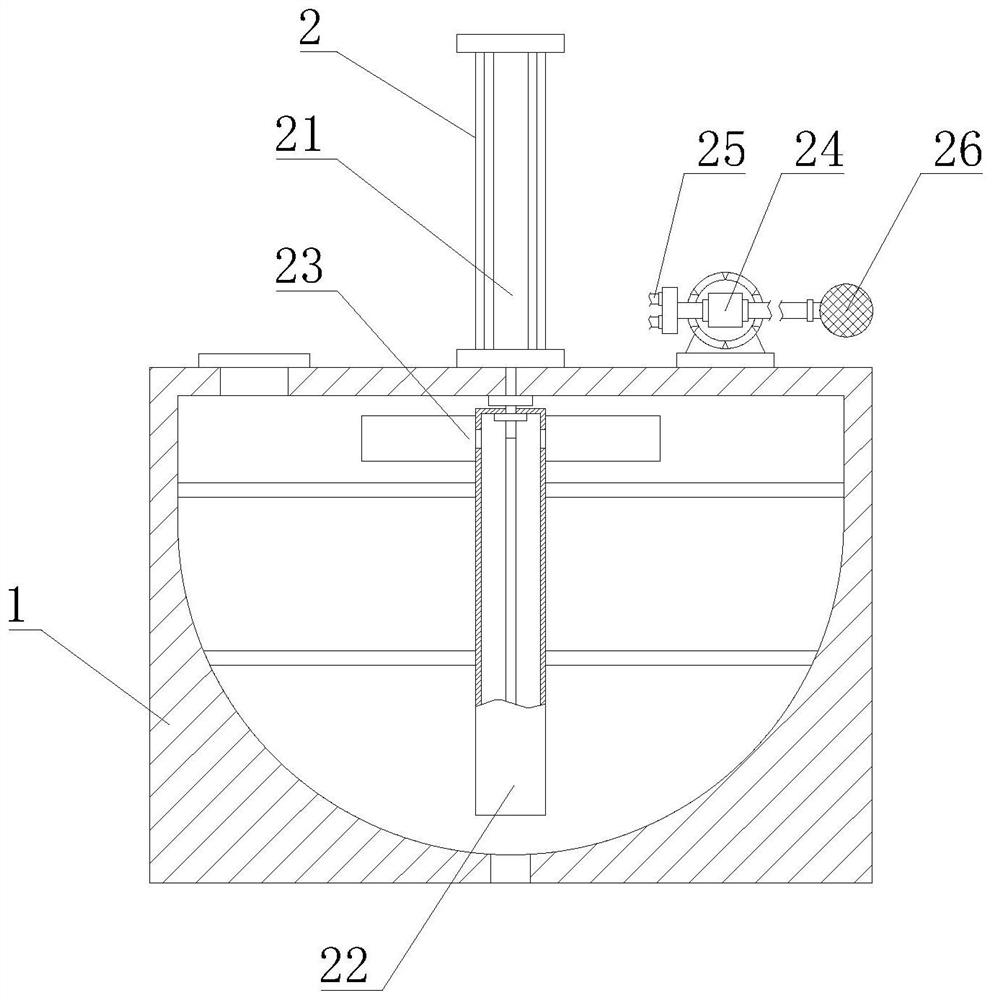

[0049] like Figure 1-12 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the cleaning device includes a processing frame 1, the front of the processing frame 1 is fixedly installed with a controller, and the top of the processing frame 1 is provided with a For the feeding chute, the top of the processing frame 1 is provided with a sufficient cleaning mechanism 2, the bottom of the processing frame 1 is provided with a low-heat drying mechanism 3, and the sufficient cleaning mechanism 2 includes an electric telescopic rod 21, a material lifting cylinder 22 and an internal circulation pump 24. The electric telescopic rod 21 is fixedly installed on the top of the processing frame body 1, the material lifting cylinder 22 is fixedly installed in the inner cavity of the processing frame body 1, and the outer wall of the material lifting cylinder 22 is fixedly connected with a discharge cleaning cylinder 23. The inner circulatio...

Embodiment 3

[0051] like Figure 1-12 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the low-heat drying mechanism 3 includes a drying processing frame 31, and the drying processing frame 31 is fixedly connected to the bottom of the processing frame body 1, and the drying The top and bottom of the inner wall of the drying frame 31 are fixedly connected with an electric butterfly valve 32 , and one end of the electric butterfly valve 32 away from the inner wall of the drying frame 31 is fixedly connected with a rubber tube 34 , and one end of the rubber tube 34 away from the electric butterfly valve 32 is fixedly connected with a temporary storage device. The mesh cylinder 35, the top and bottom of the inner wall of the drying processing frame 31 are fixedly installed with elastic feet 33, and one end of the elastic feet 33 away from the inner wall of the drying processing frame 31 is fixedly connected to the outer wall of the tempora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com