Automatic feeding type multi-dimensional processing device for electric guitar handle

An automatic feeding and processing device technology, applied in the field of musical instrument processing, can solve the problems of non-standard cutting size, hidden dangers of production safety, and reduced work efficiency, and achieve the effects of ensuring flatness, reducing labor intensity, and saving time and effort in cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the specific embodiments of the present invention are described in detail below with reference to the accompanying drawings.

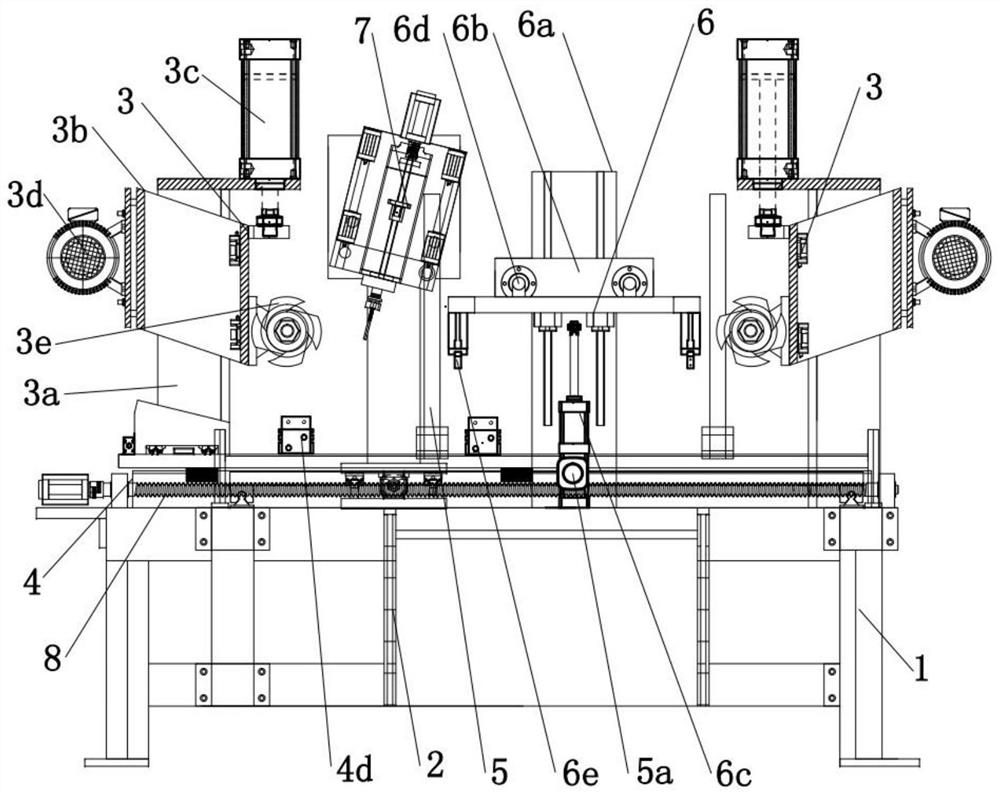

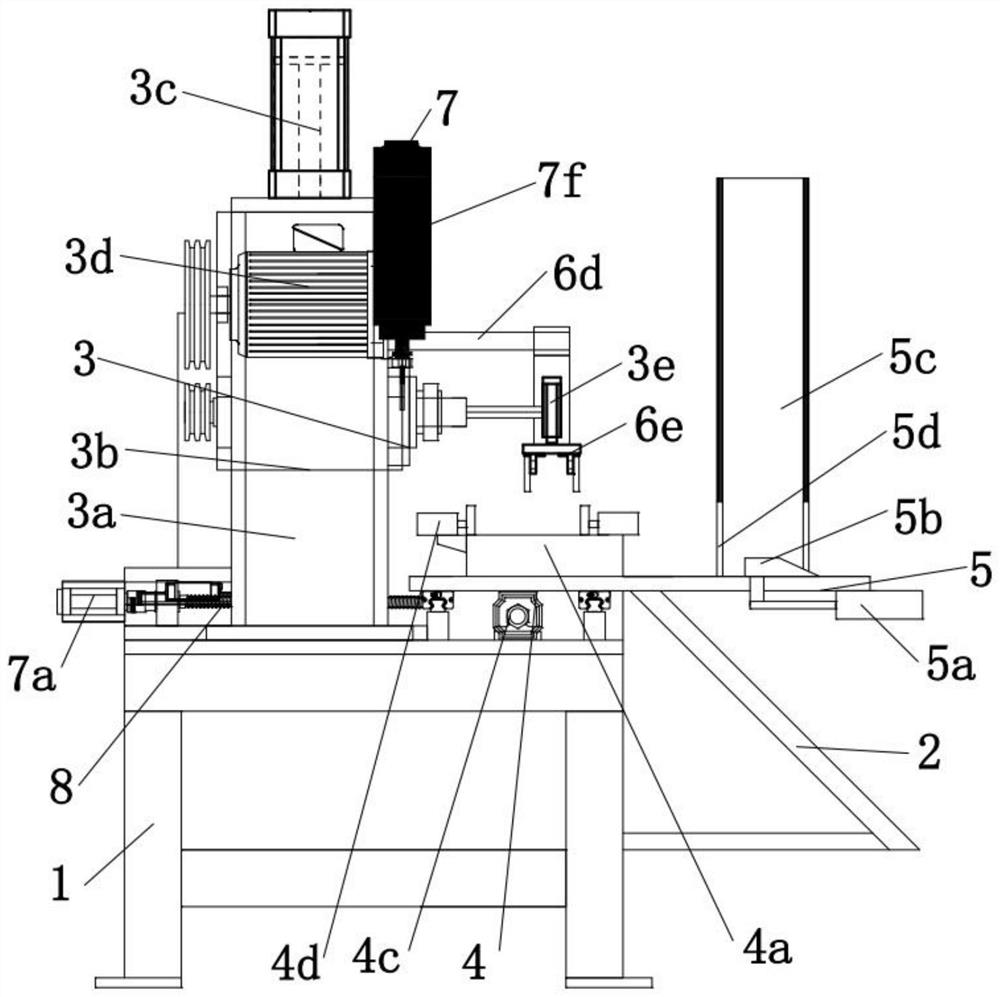

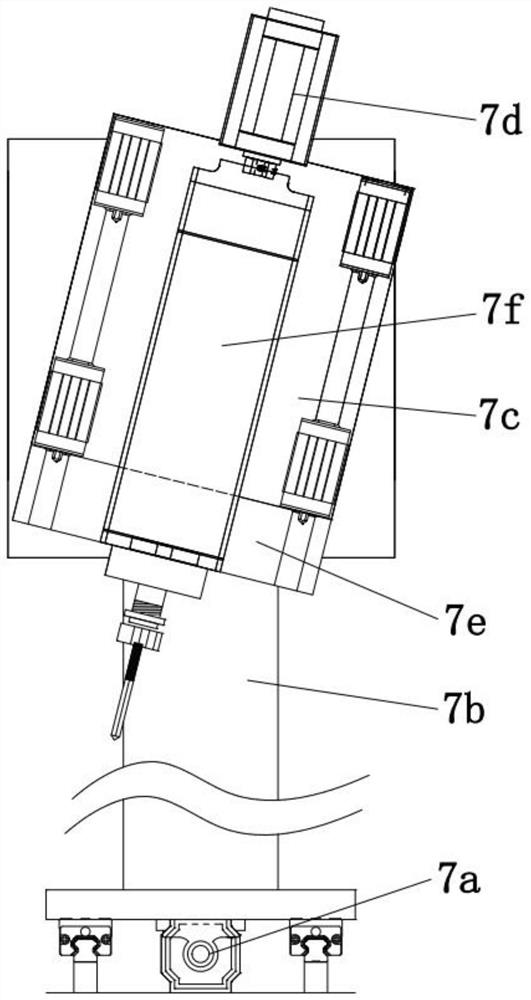

[0017] like Figures 1 to 5 The shown automatic feeding type multi-dimensional processing device for electric guitar handles includes a frame assembly 1, the top of the frame assembly 1 is a workbench, and a storage mechanism 5 is provided on the front edge of the workbench. , corresponding to the material storage mechanism 5 at the rear edge of the worktable, a grabbing mechanism 6 is provided, and a clamping and feeding mechanism 4 is provided on the worktable between the material storage mechanism 5 and the grabbing mechanism 6, and the clamping and feeding mechanism 4 is provided. The mechanism 4 is parallel to the long axis line of the workbench, and the shank processing mechanism 3 perpendicular to its long axis line is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com