Spraying equipment for anti-corrosion treatment of surface of metal material and spraying process of spraying equipment

A technology for metal materials and spraying equipment, applied in spray booths, spray devices, cleaning methods and tools, etc., which can solve problems such as inconvenient use and limited accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

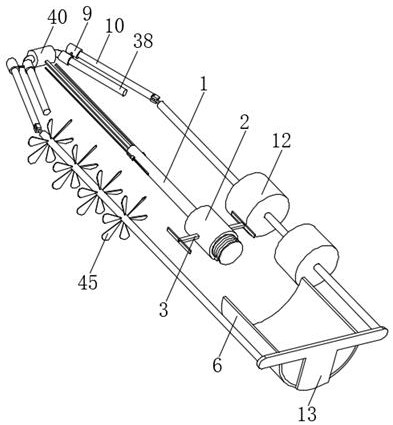

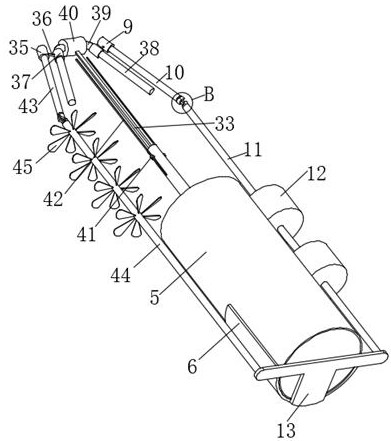

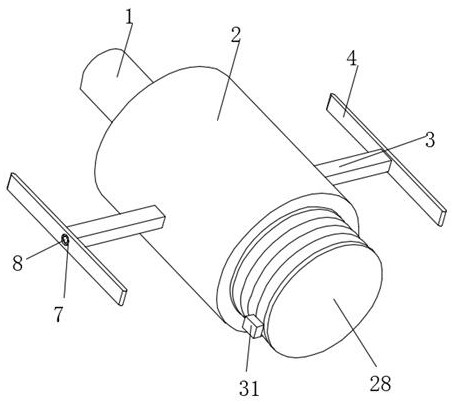

[0037]The present invention provides a technical solution: a spraying device for anti-corrosion treatment on the surface of metal materials, comprising a connecting pipe 1, the end of the connecting pipe 1 is fixedly connected with a gas storage shell 2, and the gas storage shell 2 is driven by the connecting pipe 1 to The axial movement in the metal pipe 5 to be sprayed, the arc profile of the gas storage shell 2 is provided with a through hole, and the insertion rod 3 is slidably connected in the hole. The scraper 4 for scraping and cleaning the inner wall of the sprayed metal pipe 5 is supported by the plunger 3, so that the side of the scraper 4 away from the plunger 3 can be in contact with the inner wall of the metal pipe 5 to be sprayed. The rotation of the metal pipe 5 to be sprayed and the axial movement of the scraper 4 along with the gas storage shell 2 in the metal pipe 5 to be sprayed can make the scraper 4 clean the inner wall of the metal pipe 5 to be sprayed com...

Embodiment 2

[0044] On the basis of the first embodiment, further: the liquid storage shell 14 is provided with a discharging device, and the discharging device includes a through hole opened on the end of the liquid storage shell 14 facing the elastic three-way pipe 15, and the hole is A truncated truncated sealing plug 16 is slidably connected to the axial limit, and a tension spring 17 is fixedly connected to the inner wall of the liquid storage shell 14 close to the truncated truncated sealing plug 16, and an annular tension spring 17 is fixedly connected to one end of the tension spring 17 away from the elastic three-way tube 15. Plate 18, the inner wall of the annular pull plate 18 is fixedly connected with an axial pull rod 19, and one end of the axial pull rod 19 facing the elastic tee tube 15 is fixedly connected with the end of the circular truncated sealing plug 16, and the arc contour of the axial pull rod 19 is Two symmetrical rotating arms 20 are rotatably connected through th...

Embodiment 3

[0047] On the basis of the second embodiment, further: the gas storage shell 2 is provided with a transmission device, and the transmission device includes a piston plate 22 which is limited and slidably connected to the inner wall of the gas storage shell 2, and the piston plate 22 is penetrated by the liquid storage shell 14 and is connected to the inner wall of the gas storage shell 2. The liquid storage shell 14 is movably connected, the side of the piston plate 22 away from the elastic infusion tube 101 is fixedly connected with a guide rod 1 23, and the end of the guide rod 1 23 away from the piston plate 22 is fixedly connected with a guide rod 2 24, the guide rod 2 24 One end away from the guide rod 1 23 is fixedly connected with a guide rod 3 25. The surface of the insertion rod 3 is provided with a guide hole 26 for the movement of the guide rod 1 23, the guide rod 2 24 and the guide rod 3 25. The piston plate 22 is far away from the guide rod. One side of the rod one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com