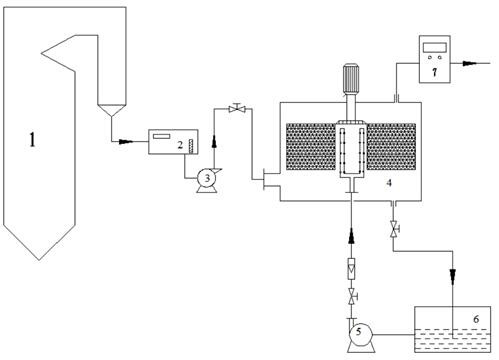

Method and device for removing multi-component pollutants in flue gas based on supergravity technology

A multi-component and pollutant technology, applied in the field of flue gas purification, can solve the problems of increasing system operating costs and low activation efficiency, and achieve the effect of small footprint, low cost and resource reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

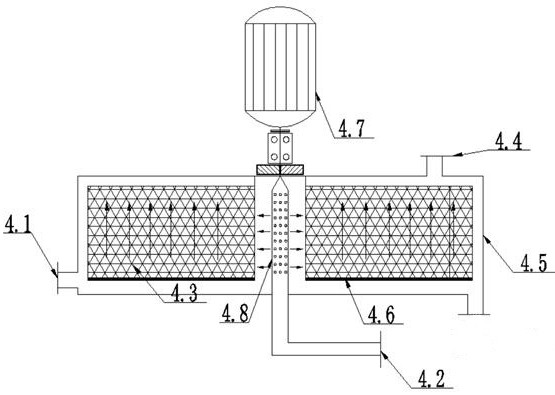

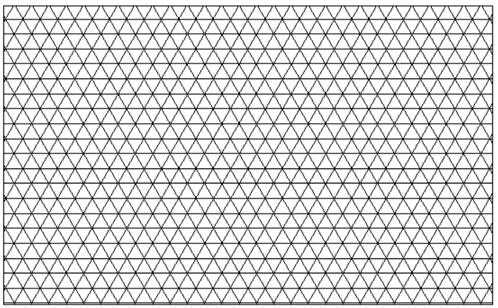

[0057] The described filler for enhancing gas-liquid mass transfer is specifically prepared by the following method:

[0058] (1) The filler is composed of metal wires, and the metal wires are arranged in a cross to form a mesh of diamond-shaped holes, and the area of the diamond-shaped holes is about 0.6~0.8cm 2 .

[0059] (2) In the radial direction, the cross-arranged metal wires are corrugated.

[0060] (3) Roll the wire mesh with the above structure into cylinders with different diameters, leaving a gap of 2-3 mm between the two cylinders, and then fix them on the lower tray of the filler.

Embodiment 1

[0063] Preparation of absorption liquid, specific components: (NH 4 ) 2 S 2 O 8 Concentration is 0.2 mol / L, H 2 O 2 Concentration of 0.3 mol / L, FeSO 4 Concentration of 0.01 mol / L, CuSO 4 The concentration is 0.01 mol / L. Turn on the hypergravity machine and set the hypergravity factor to 70. The absorbing liquid was injected into the rotating packed bed from the liquid inlet using a centrifugal pump, and the liquid flow rate was 100 L / h. The NO gas injection machine is in full contact with the liquid, and the gas flow rate is 1000 L / h. NO, SO 2 , Hg 0 The removal rates were 76.25%, 95.43% and 75.85%, respectively.

Embodiment 2

[0065] Preparation of absorption liquid, specific components: (NH 4 ) 2 S 2 O 8 Concentration is 0.5 mol / L, H 2 O 2 Concentration of 0.8 mol / L, FeSO 4 Concentration of 0.08 mol / L, CuSO 4 The concentration is 0.08 mol / L. Turn on the hypergravity machine and set the hypergravity factor to 90. The absorbing liquid was injected into the rotating packed bed from the liquid inlet using a centrifugal pump, and the liquid flow rate was 100 L / h. The NO gas injection machine is in full contact with the liquid, and the gas flow rate is 1000 L / h. NO, SO 2 , Hg 0 The removal rates were 80.13%, 96.38% and 77.48%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com