Preparation method and application of nanosheet vanadium phosphorus oxygen catalyst for strengthening microscopic mixing and reaction

A nano-sheet, vanadium-phosphorus-oxygen technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve the problems of high specific surface area, few deep oxides, low reaction rate, etc., to improve the specific surface area. , the effect of accelerating the reaction rate and enhancing the mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

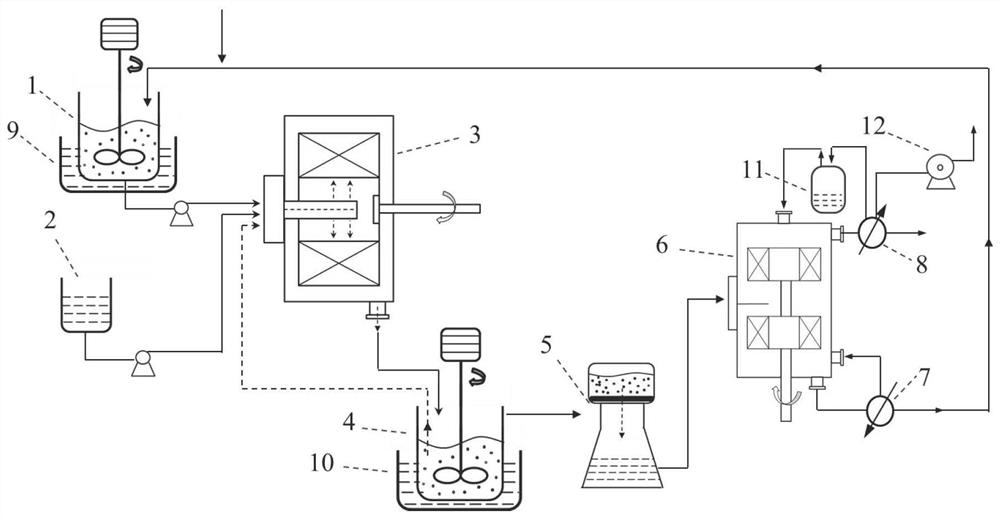

[0053] As an aspect of the present invention, a method for preparing a nano-sheet vanadium-phosphorus-oxygen catalyst that strengthens microscopic mixing and reaction of the present invention comprises the following steps:

[0054] S1, V 2 o 5 Dissolving Reduction in a Stirred Kettle

[0055] will V 2 o 5 Add in the first stirred tank 1, then add the mixed solvent of isobutanol and benzyl alcohol into the first stirred tank, start stirring, heat and keep warm through the first oil bath heating device 9, and the temperature in the first stirred tank 1 is controlled at 110-112 ℃ for dissolution and reduction reaction, after the reaction to obtain a vanadium-containing suspension A; the purpose of this step is to make V 2 o 5 Dissolving and reducing to part of tetravalent vanadium suspension;

[0056] S2, supergravity enhanced phosphoric acid is mixed and reacted with the tetravalent vanadium suspension in step S1:

[0057] Pass the phosphoric acid / isobutanol mixed solutio...

Embodiment 1

[0075] A preparation method and application of a nano-sheet vanadium-phosphorus-oxygen catalyst that strengthens microscopic mixing and reaction, comprising the following steps:

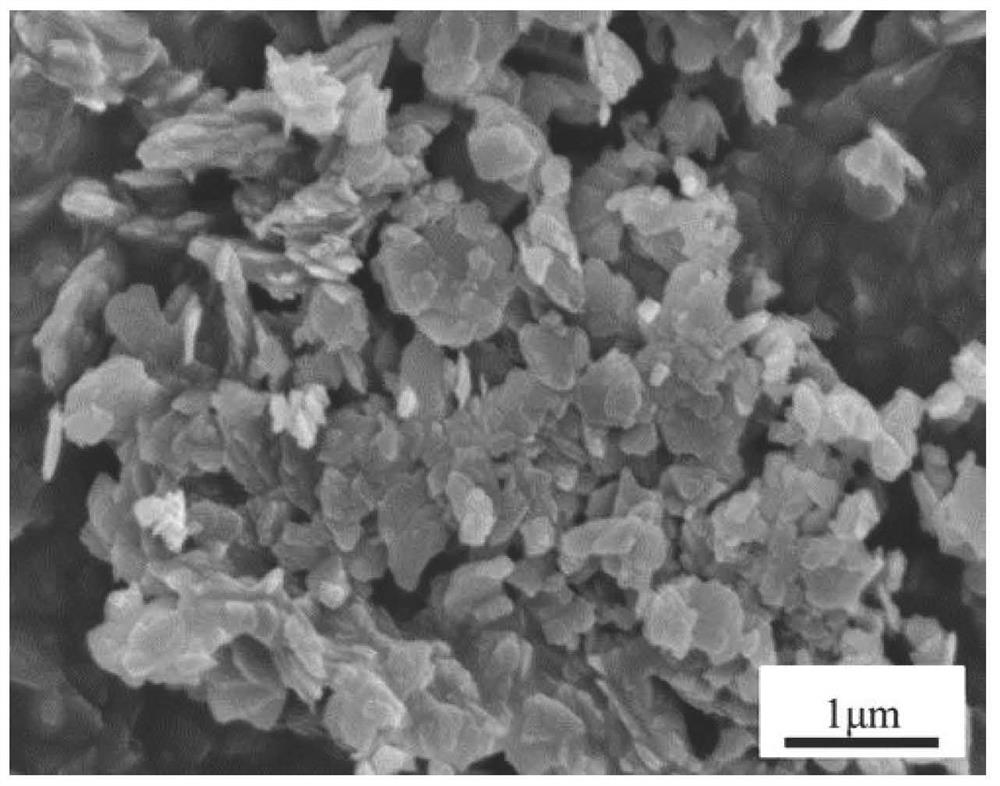

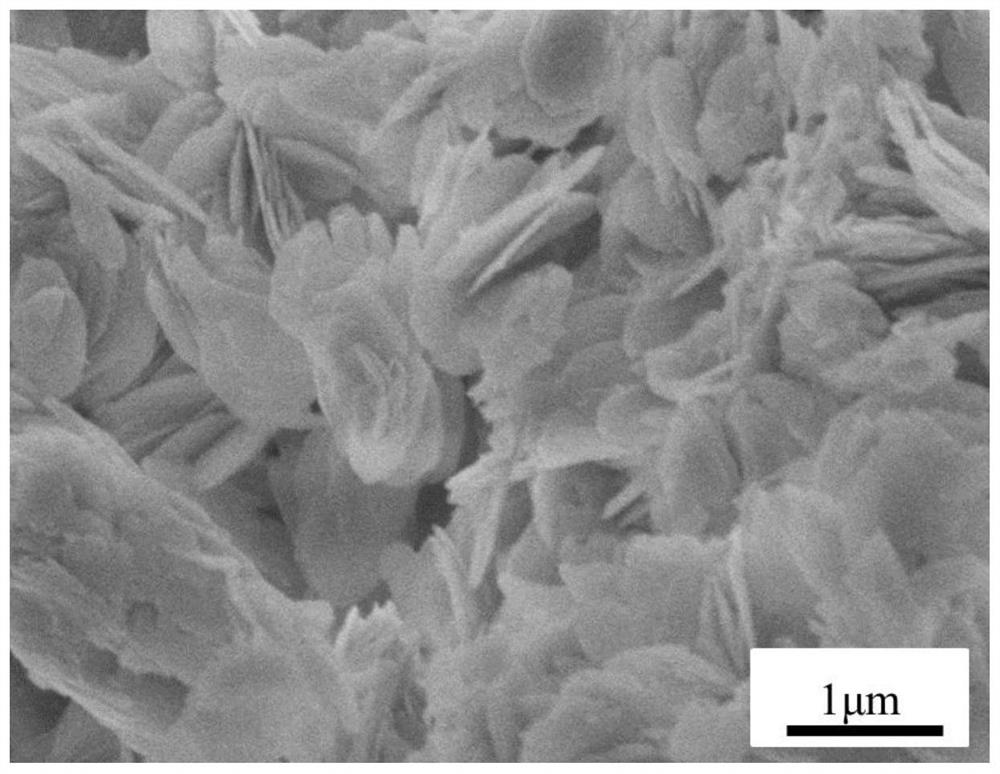

[0076] will V 2 o 5 Add it into the first stirred tank 1, then add the mixed solvent of isobutanol and benzyl alcohol into the first stirred tank 1, start stirring, and heat and keep it through the first oil bath heating device 9. The temperature of the oil bath is 140°C. The actual temperature is 111.4 ° C, the obtained vanadium-containing suspension A; the obtained vanadium-containing suspension A and phosphoric acid / isobutanol mixed solution are passed into the first high-gravity reactor 3, the speed is 1500r / min, and the two materials It is pre-mixed by a pre-mixer for preliminary mixing, and then enters the liquid distributor with injection holes to spray into the high-speed packing; then enters the second stirring tank 4 through the discharge port, and part of the materials in the stirring tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com