Modularized large-current parallel starting and generating integrated controller and control method

A high-current, controller technology, applied in the direction of motor generator control, electromechanical brake control, DC power supply parallel operation, etc., can solve the problems of multi-structure of mechanical components, heavy system weight, etc., to reduce line routing, Guarantee normal work and universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

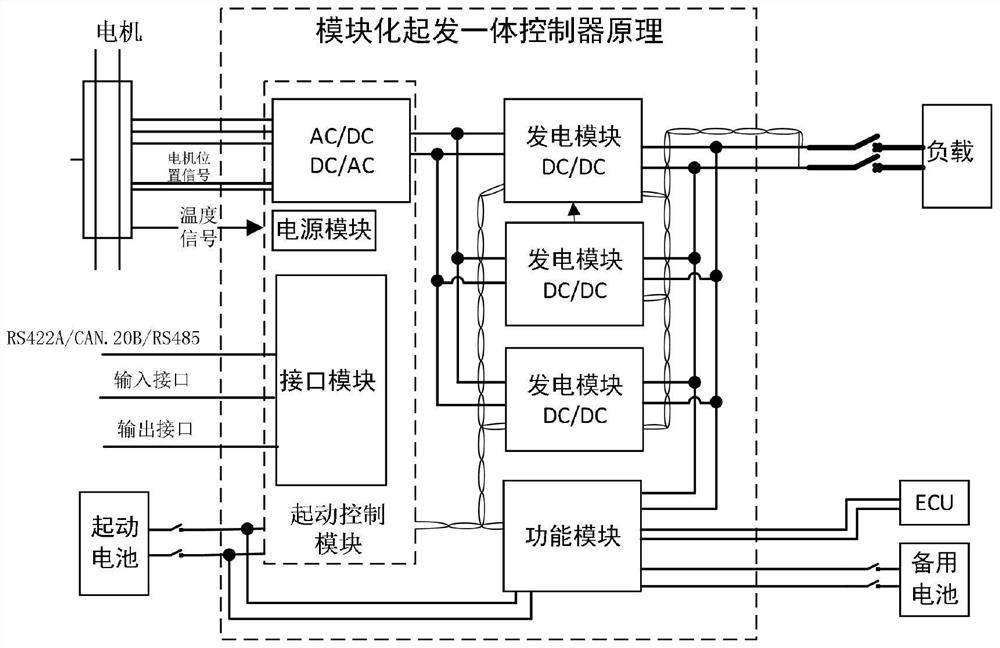

[0043] see Figure 1-2 , a modular high-current parallel start-up integrated controller, consisting of a starter module, three power generation modules and a function module, the whole controller adopts forced air cooling, the starter battery is a lithium battery with a rated voltage of 26VDC, and the backup battery The rated voltage of the lithium battery is 26VDC, and the power generation output voltage of the integrated controller is 28VDC;

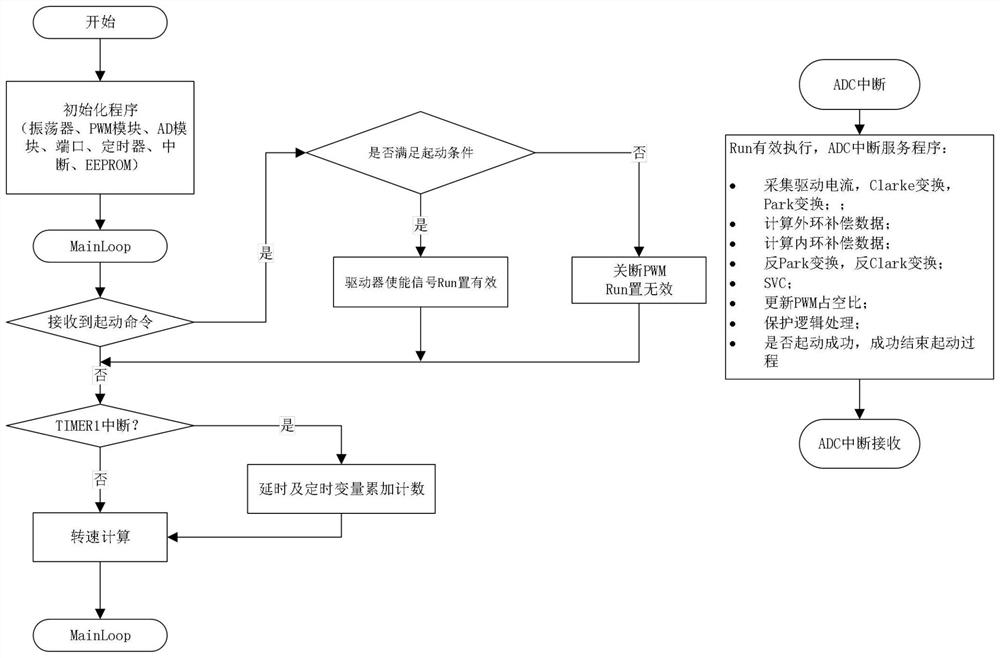

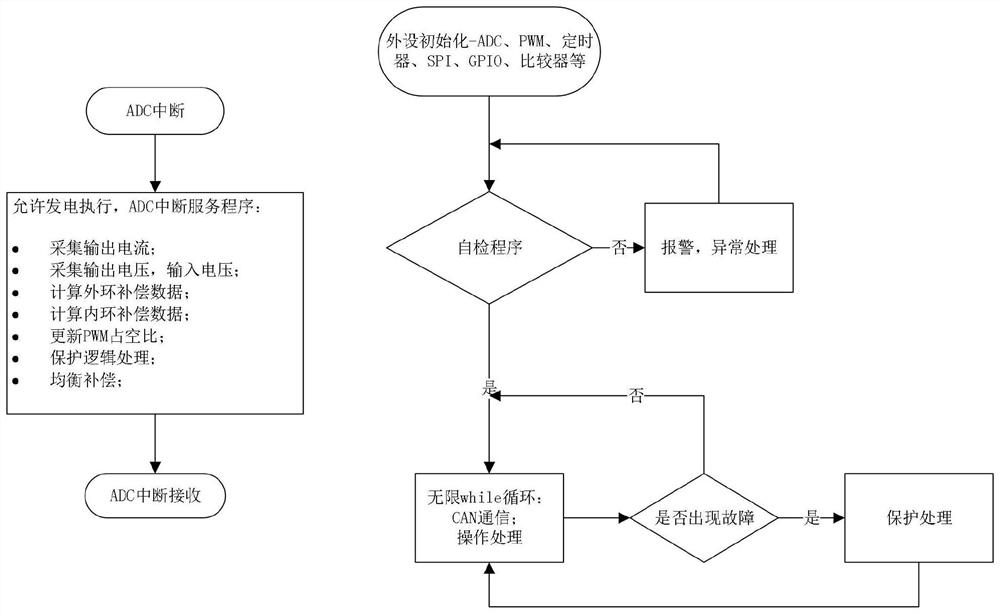

[0044] The three-phase input of the starting module is connected to the aerial plug of the shell through the high-current terminal, and adopts the vector control with Hall. The hall signal is connected to the starting module through the aerial plug wiring harness. The starting module communicates externally through RS422, CAN2.0B, and RS485. 8-channel DI and 4-channel DO output, communicate with the power generation module and function module through CAN2.0B to obtain data and send commands, the maximum output current of the starting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com