High-efficiency low-strontium-consumption 4004 aluminum alloy modification method

A technology of aluminum alloy and aluminum alloy melt, which is applied in the field of aluminum alloy preparation, can solve the problems of 4004 aluminum alloy such as coarse silicon phase, unstable modification effect, and high strontium residue, and achieve stable modification effect, easy operation, and low strontium residue low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

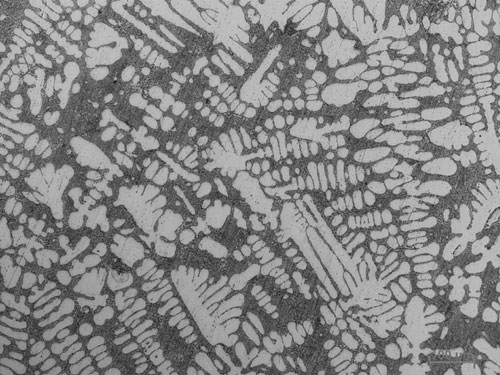

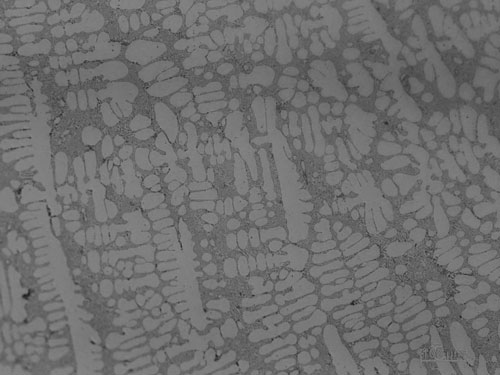

Image

Examples

Embodiment 1

[0029] A 4004 aluminum alloy modification method with high efficiency and low strontium consumption. The steps of the method include: batching calculation and smelting: calculating the addition amount of aluminum ingots and additives according to the chemical composition of 4004 aluminum alloy, and smelting, and the smelting temperature is 700 ℃-730 ℃ , adjust the chemical composition to meet the standard. The total amount of aluminum ingots and additives added in this step is 36643kg;

[0030] In-furnace refining: a "T" type refiner is used, and the refining gas is argon to keep the refiner moving smoothly and slowly in the lower layer of the melt, throughout the melt. The refining time is 30min, and the refining temperature is 710℃-730℃;

[0031] Slag removal: remove the scum in the furnace;

[0032] Metamorphism: Add 30kg of aluminum-strontium alloy block with strontium content of 10%;

[0033] Standing: standing for 1 hour, adjust the temperature in the furnace to a rea...

Embodiment 2

[0040] A 4004 aluminum alloy modification method with high efficiency and low strontium consumption. The steps of the method include: batching calculation and smelting: calculating the addition amount of aluminum ingots and additives according to the chemical composition of 4004 aluminum alloy, and smelting, and the smelting temperature is 700 ℃-730 ℃ , adjust the chemical composition to meet the standard. The total amount of aluminum ingots and additives added in this step is 35506kg;

[0041] In-furnace refining: a "T" type refiner is used, and the refining gas is argon to keep the refiner moving smoothly and slowly in the lower layer of the melt, throughout the melt. The refining time is 30min, and the refining temperature is 710℃-730℃;

[0042] Slag removal: remove the scum in the furnace;

[0043] Metamorphism: Add 30kg of aluminum-strontium alloy block with strontium content of 10%;

[0044] Standing: standing for 1 hour, adjust the temperature in the furnace to a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com