A single-screw refiner

A refiner and single-screw technology, which is applied in the field of pulp and papermaking, can solve the problems of difficulty in guaranteeing the quality of pulp refining, difficult processing of convex and concave arrays, and no popularization and application, and achieve the effects of simplified structure, convenient manufacturing and processing, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

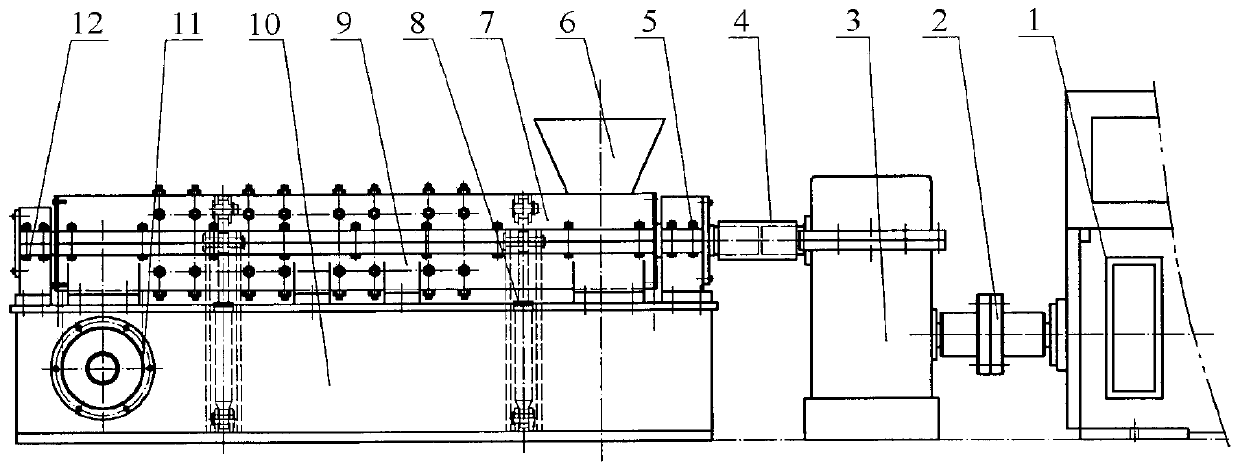

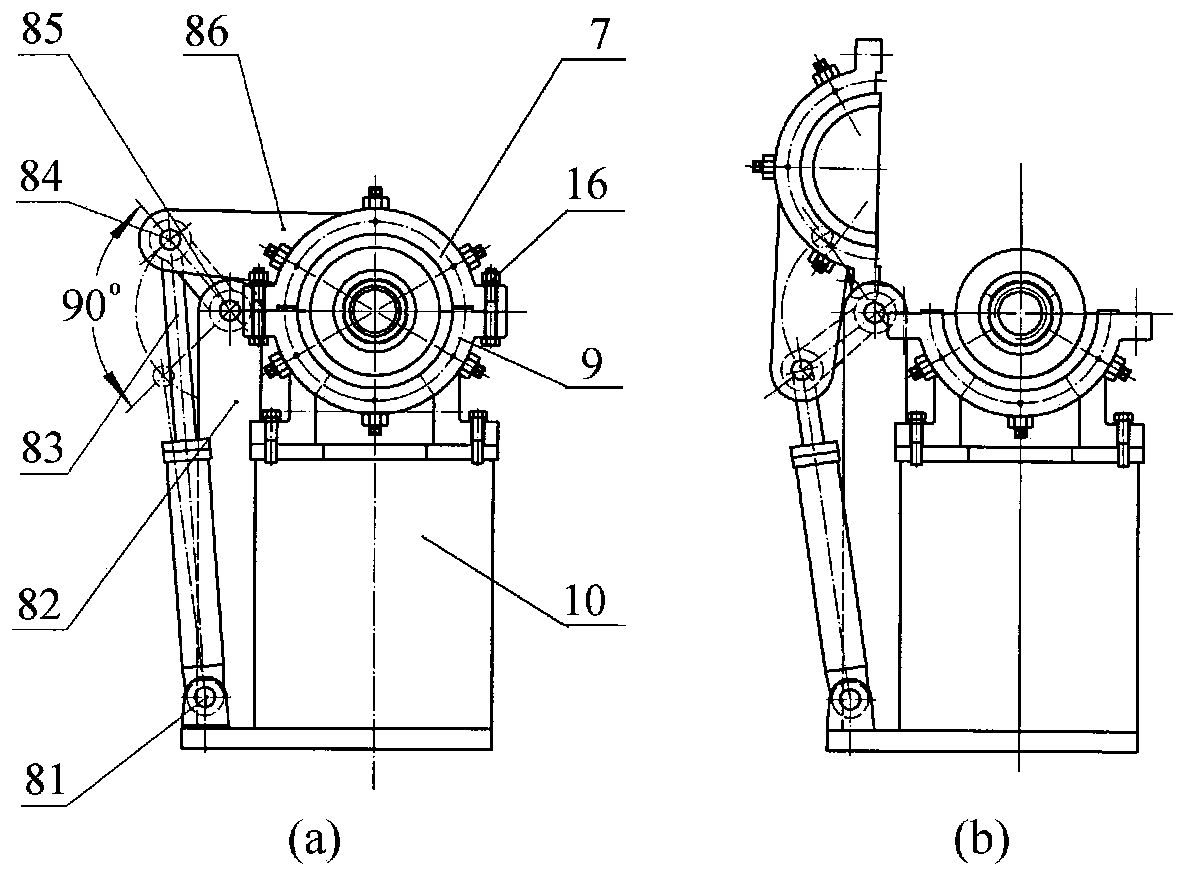

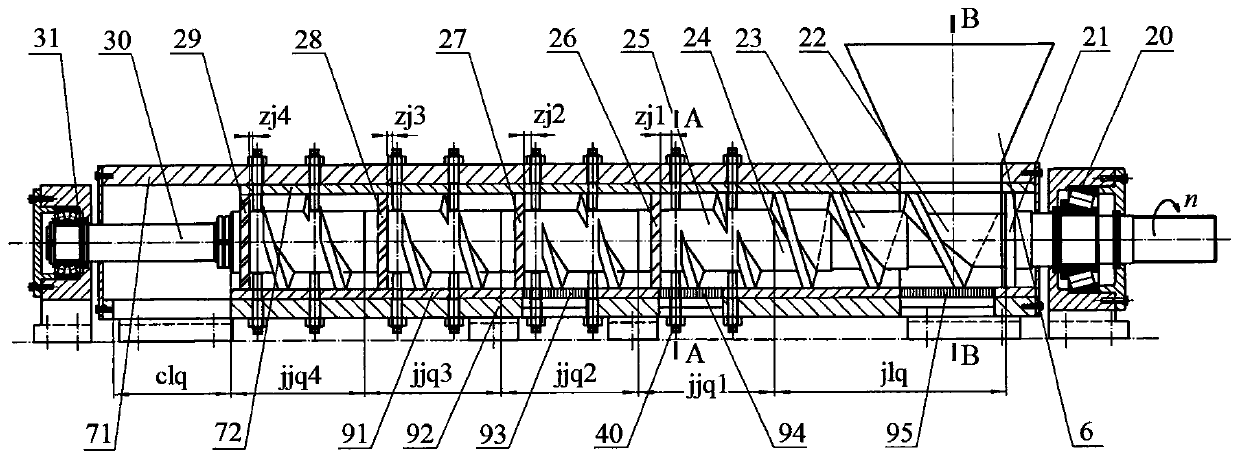

[0041] Such as figure 1 As shown, a single-screw refiner includes a machine base 10, a barrel base 9, a barrel cover 7, a front bearing seat 5, a rear bearing seat 12, a screw, a coupling 4, a reducer 3, and an elastic coupling Device 2 and motor 1, fixedly install machine barrel seat, front bearing seat and rear bearing seat on the machine base, front bearing seat and rear bearing seat respectively install screw rod, machine barrel seat and machine barrel cover through front bearing 20 and rear bearing 31 The barrel is connected by connecting bolts 16, the front end of the screw is connected to the reducer through a coupling, the reducer is connected to the motor through an elastic coupling, a feed port 6 is provided on the cover of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com