Synchronous nitrogen and carbon removal method for sewage with low carbon-nitrogen ratio

A technology with low carbon-to-nitrogen ratio and carbon-to-nitrogen ratio, applied in the field of synchronous denitrification and carbon removal of sewage with low carbon-to-nitrogen ratio, can solve the problem that the treatment cost is difficult to further reduce, and overcome the shortage of organic carbon sources, aeration volume and aeration The effect of reducing time and overcoming technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] (1) Configure simulated water inflow

[0077] For MBR, add solutes in deionized water to configure simulated influent with the following components:

[0078] CH 3 COONa 440mg / L, C 3 H 5 O 3 Na 130mg / L, C 7 H 6 O 2 50mg / L, (NH 4 ) 2 SO 4 165mg / L, NaHCO 3 250mg / L, KH 2 PO 4 50mg / L, MgSO 4 ·7H 2 O 50mg / L, ZnSO 4 ·7H 2 O 100mg / L, MnCl 2 ·4H 2 O 30mg / L, H 3 BO 3 300mg / L, CoCl 2 ·6H 2 O 200mg / L, CuCl 2 ·2H 2 O 10mg / L, NiCl 2 ·6H 2 O 10mg / L, Na 2 SeO 3 30mg / L, NH 4 Cl 305mg / L; use 1mol / L HCl solution to adjust the pH range to 7.2-7.6, and use an autoclave to sterilize the simulated influent water.

[0079] For MBfR, the simulated influent was configured by adding solutes in deionized water, with the following components:

[0080] NO 3 - -N 30mg / L, NaHCO 3 250mg / L, KH 2 PO 4 33mg / L, MgSO 4 ·7H 2 O 50mg / L, ZnSO 4 ·7H 2 O 100mg / L, MnCl 2 ·4H 2 O 30mg / L, H 3 BO 3 300mg / L, CoCl 2 ·6H 2 O 200mg / L, CuCl 2 ·2H 2 O10mg / L, NiCl 2 ·...

Embodiment 2

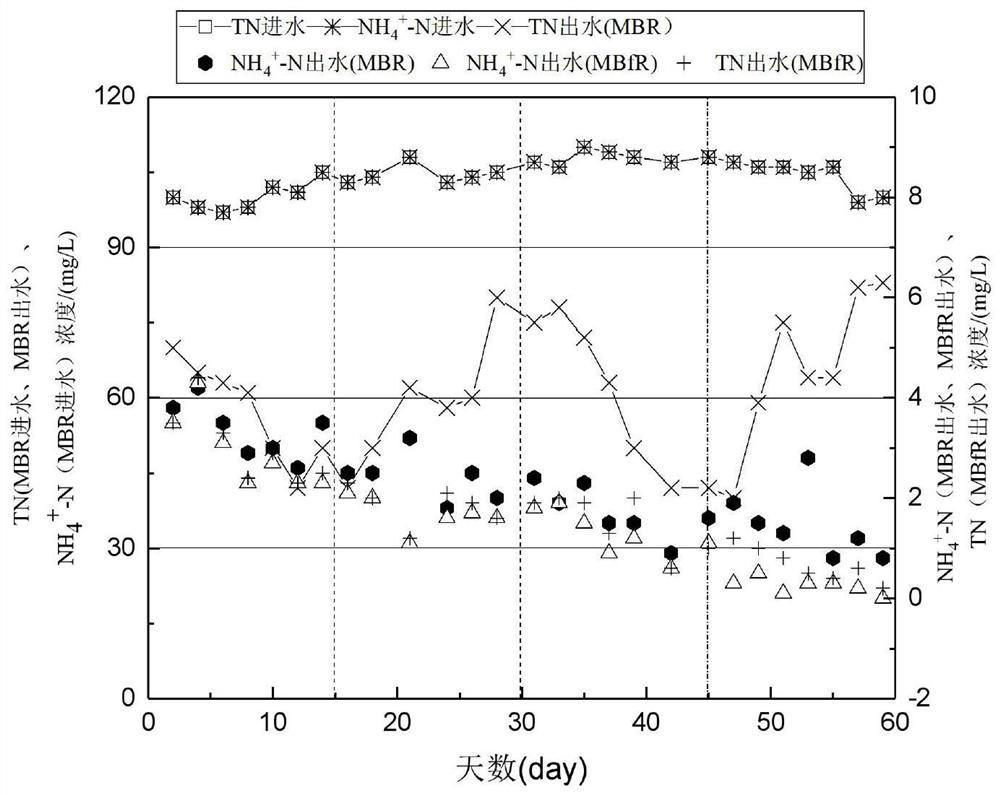

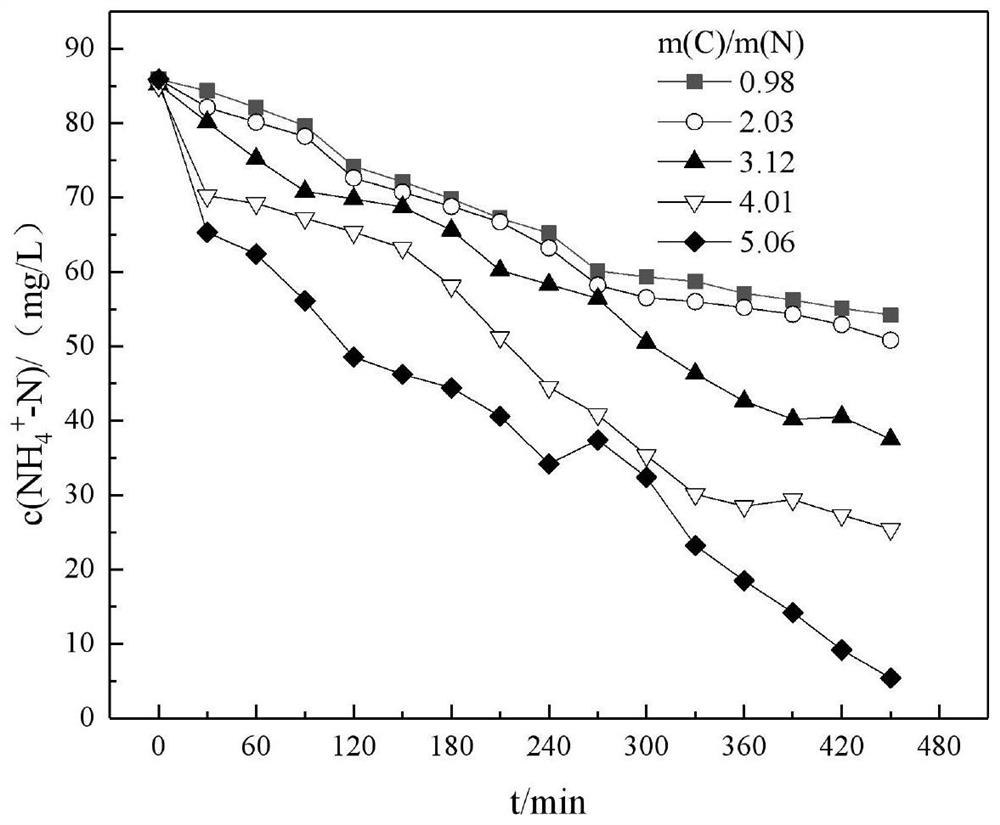

[0104] The anaerobic tank influent of a sewage treatment plant in Guilin is used as the actual influent of the process, and different C / N ratios are achieved by artificially adding ammonia nitrogen (specifically ammonium chloride) and starch to investigate different C / N ratios. The effect of conditions on the simultaneous denitrification and carbon removal of this process.

[0105] At the beginning of the run, the acclimation of MBR and MBfR was initiated separately. In MBR, 250 mL of nitrified sludge that has been domesticated in the laboratory is used as the inoculation source, and the inoculation amount is 10% of the effective volume of MBR; The mixed sludge of the mature hydrogen autotrophic denitrifying bacteria in the chamber was used as the inoculum source in a volume ratio of 2.6:1, and the total inoculum amount was 10% of the effective volume of MBfR.

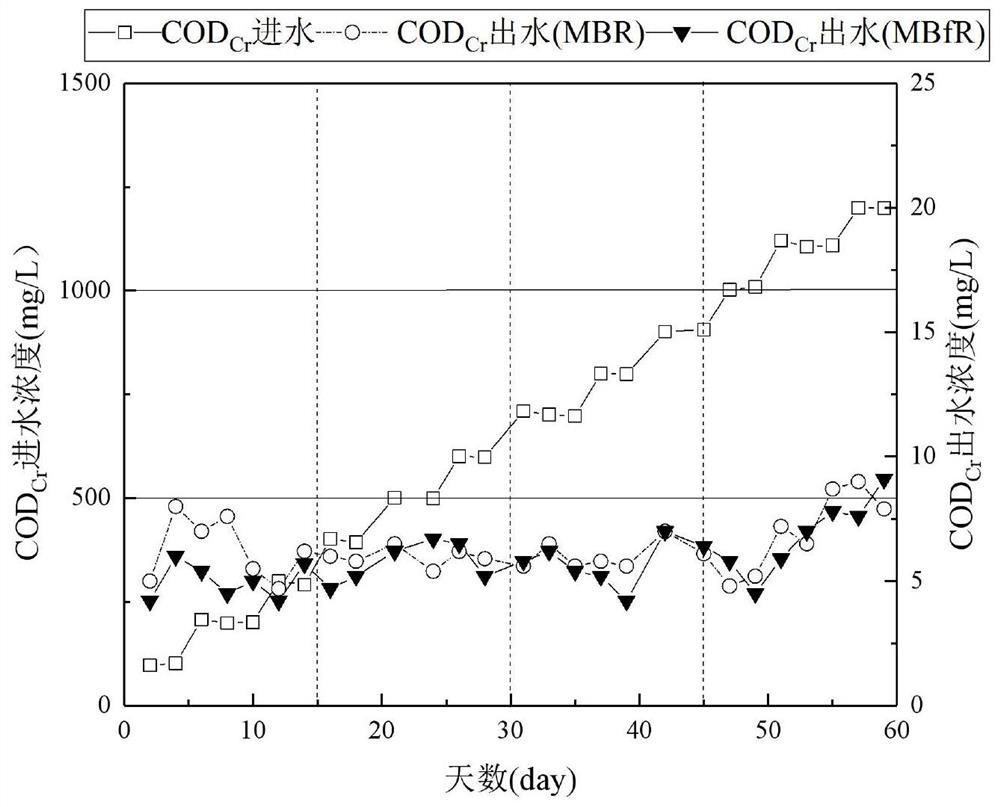

[0106] In MBR, water feed rate is 1.0mL / min; air diffuser provides oxygen for aerobic nitrification and organic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com