Method for preparing metal transition layer by plasma cladding

A technology of plasma cladding and transition layer, applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of difficult linking of titanium and iron, easy occurrence of brittle phase, poor composite property, etc., and achieve poor cladding accuracy , large cladding deformation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

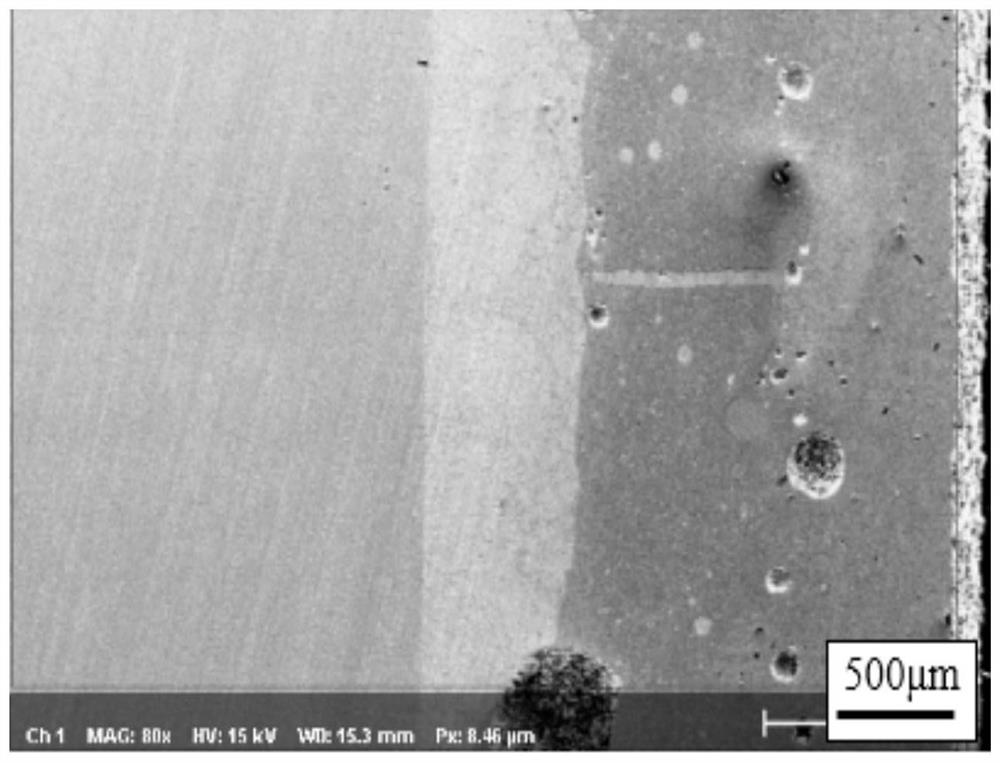

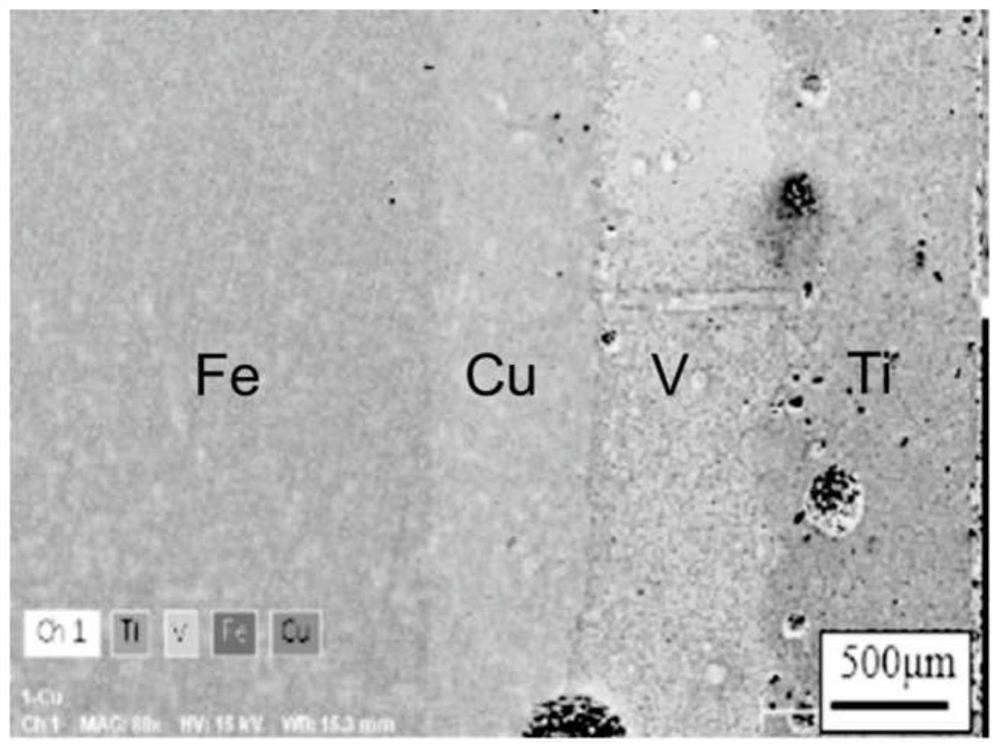

[0090] The clean Q235 steel obtained after pretreatment is used as the base material, and the base material is placed on the plasma cladding workbench. Into the powder feeder of the plasma cladding equipment, using the method of synchronous powder feeding.

[0091] Set the plasma cladding process parameters as:

[0092] Working current 130A, working voltage 20V, scanning speed 0.08m / min, powder feeding gas (Ar) volume flow rate: 0.3m 3 / h, plasma working gas (Ar): 0.3m 3 / h, protective gas (Ar): 0.3m 3 / h.

[0093] Start the switch to start the plasma cladding preparation of the transition layer, and complete the preparation of the copper transition layer on the surface of the base material.

[0094] On this basis, after the same conventional surface pretreatment as that of the base material, including descaling and degreasing, the base material prepared with a copper transition layer is placed on the plasma workbench, and V Powder, gum arabic and deionized water are mixe...

Embodiment 2

[0105] The clean Q235 steel obtained after pretreatment is used as the base material, and the base material is placed on the plasma cladding workbench. Into the powder feeder of the plasma cladding equipment, using the method of synchronous powder feeding.

[0106] Set the plasma cladding process parameters as:

[0107] Working current 130A, working voltage 10V, scanning speed 0.06m / min, powder feeding gas (Ar) volume flow: 0.3m 3 / h, plasma working gas (Ar): 0.3m 3 / h, protective gas (Ar): 0.3m 3 / h.

[0108] Start the switch to start the plasma cladding preparation of the transition layer, and complete the preparation of the copper transition layer on the surface of the base material.

[0109] On this basis, after the same conventional surface pretreatment as that of the base material, including descaling and degreasing, the base material prepared with a copper transition layer is placed on the plasma workbench, and V Powder, gum arabic and deionized water are mixed eve...

Embodiment 3

[0119] Concrete steps are identical with embodiment 1, difference is:

[0120] During the preparation of the copper transition layer, the following plasma cladding parameters were changed:

[0121] Adjust the working current to 160A;

[0122] When preparing the titanium layer, change the following plasma cladding parameters:

[0123] Adjust the working current to 200A.

[0124] A titanium layer with copper and vanadium as the transition layer was prepared on the surface of Q235 steel.

[0125] According to GB / T6396-2008, the bonding strength between the prepared titanium layer and the Q235 steel base material was detected, recorded and compared with conventional commercially available titanium-coated Q235 steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com