Ultrasonic guided wave defect quantitative detection method and application thereof

A quantitative detection method and ultrasonic guided wave technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of inability to determine the length of defects such as debonding, inability to determine the shape of defects, etc., achieving high precision and strong detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

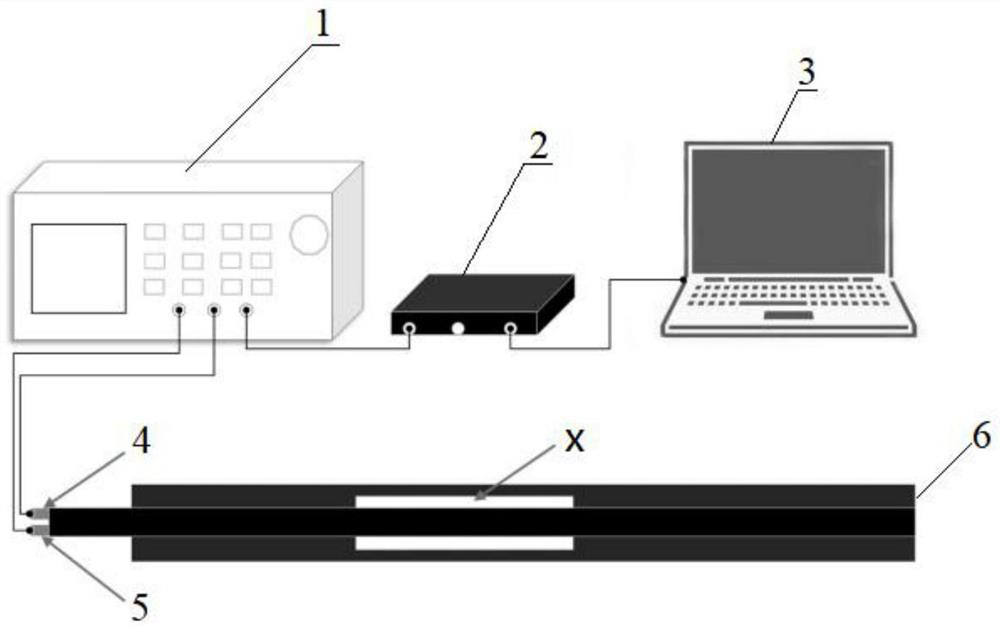

[0099] The simulation experiment is carried out by the above-mentioned embodiment:

[0100] The detection target is an anchor rod with a total length of 3m and a diameter of 2cm. The length of the anchor is 2.5m. There is a debonding defect in the middle, and the length of the defect is 0.6m.

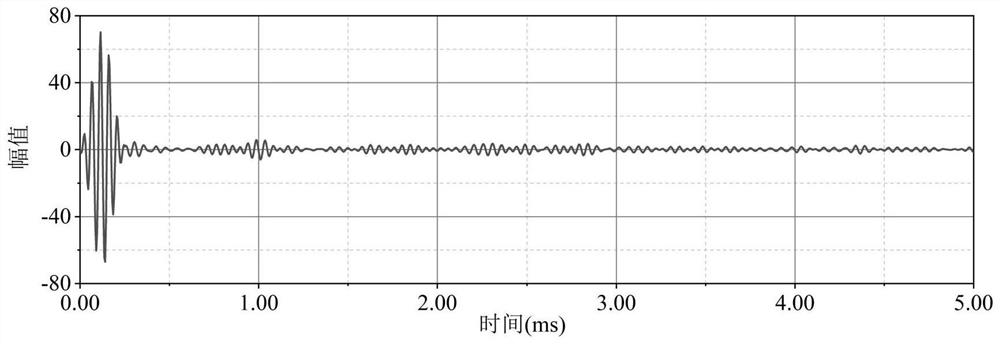

[0101] The return signal which is generated according to the above-mentioned embodiment is as follows figure 2 shown.

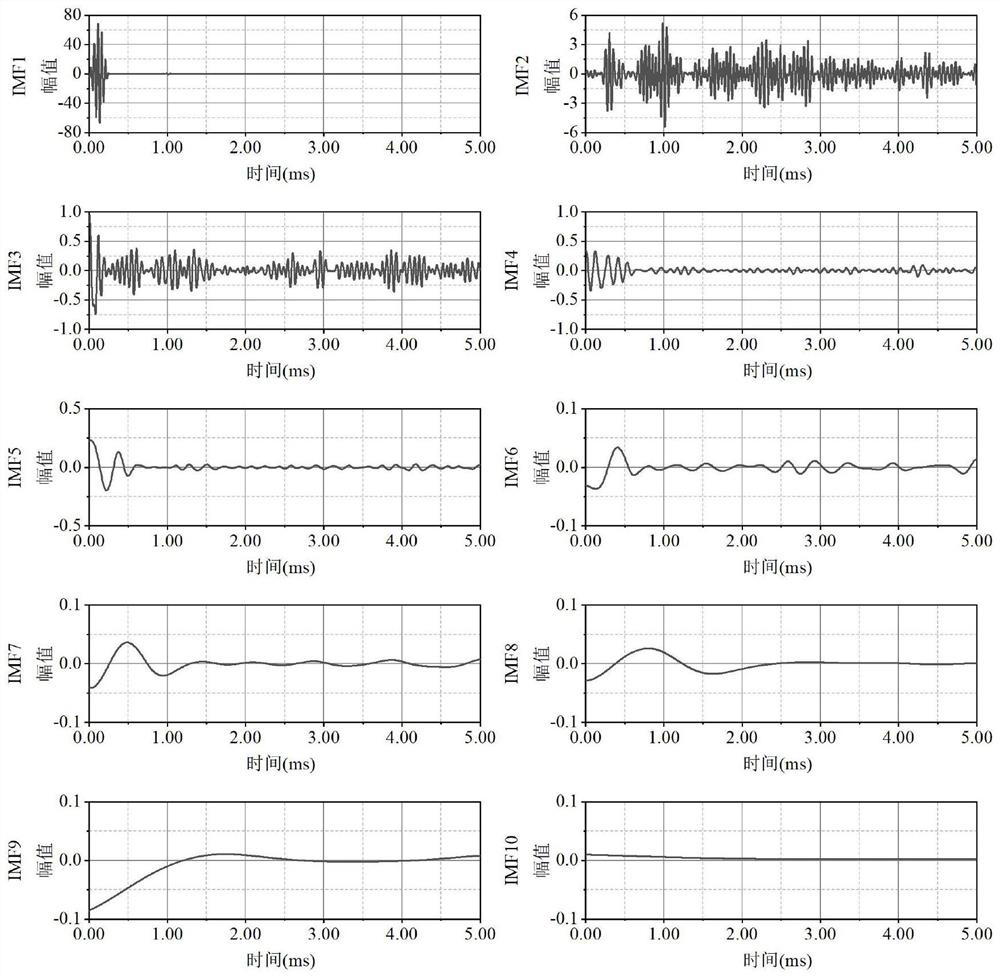

[0102] After ICEEMDAN decomposition, the 10th-order IMF is obtained, such as image 3 shown.

[0103] In order to obtain the wave speed of the ultrasonic guided wave in the steel bar and the anchored compact section, the ultrasonic guided wave detection is carried out for the free anchor with a length of 3m (that is, the anchor without the anchoring section) and the full-length anchored compact anchor according to the process of step S1. Obtain the envelope of the reflected signal, such as Figure 4 , Figure 5 shown.

[0104] Figure 4 It is the reflection wav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com