Geothermal well temperature measuring nipple

A technology of geothermal wells and pup joints, applied in geothermal energy power generation, measurement, drilling equipment, etc., can solve problems such as inability to complete geothermal field temperature monitoring, failure of geothermal field monitoring system installation, and complex process of temperature measurement system, etc., to achieve light weight , cut off heat transfer, flexible measuring point arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

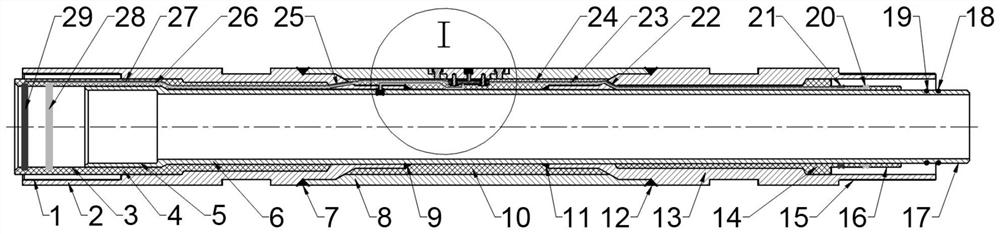

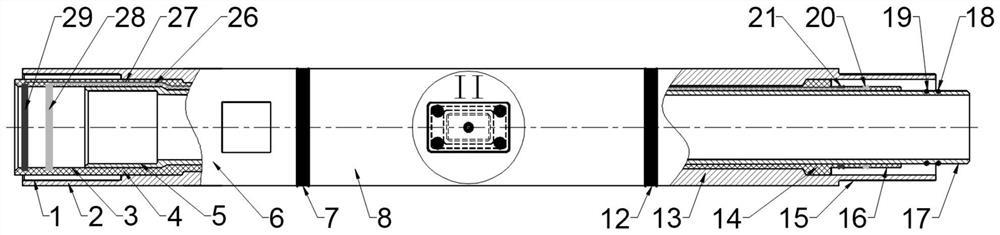

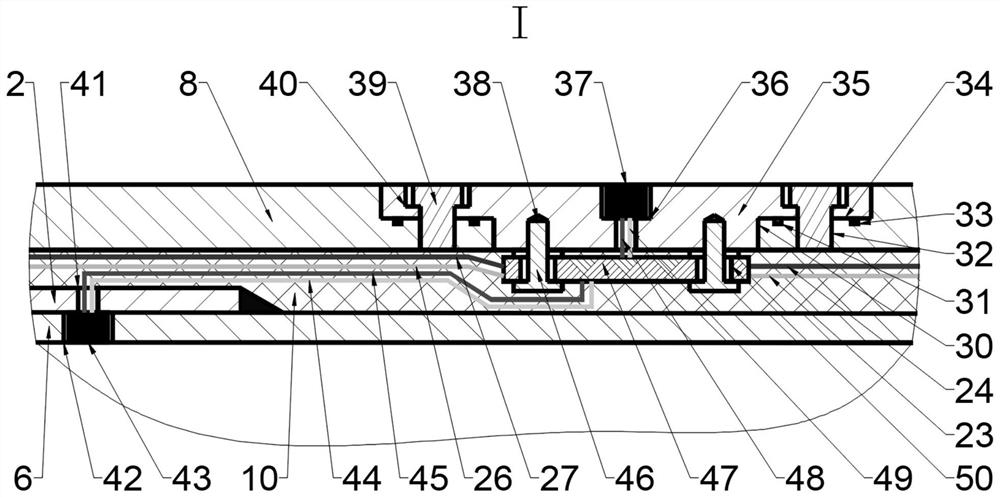

[0043] The present invention is a geothermal well temperature measuring sub, which is connected with a cable-type composite thermal insulation pipe, such as figure 1 , figure 2 , image 3 and Figure 4 As shown in the figure, the temperature measuring sub-section consists of the female thread 1 of the A-end joint, the A-end joint 2, the inner surface of the A-end thermal insulation bushing 3, the A-end thermal insulation bushing 4, and the inner surface of the A-end of the core tube 5. , core tube 6, A-end joint temperature measurement chamber outer tube weld 7, temperature measurement chamber outer tube 8, A-end joint core tube weld 9, temperature measurement chamber insulation material 10, B-end joint core tube weld 11, B-end joint temperature measurement chamber outer pipe weld 12, B-end joint 13, B-end thermal insulation bushing 14, B-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com