Partition frame type auxiliary chip removal device for circumferential array multi-station numerical control lathe

A circular array and CNC lathe technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of chip accumulation, machine downtime, etc., to avoid accumulation, improve processing efficiency, and avoid automatic shutdown. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

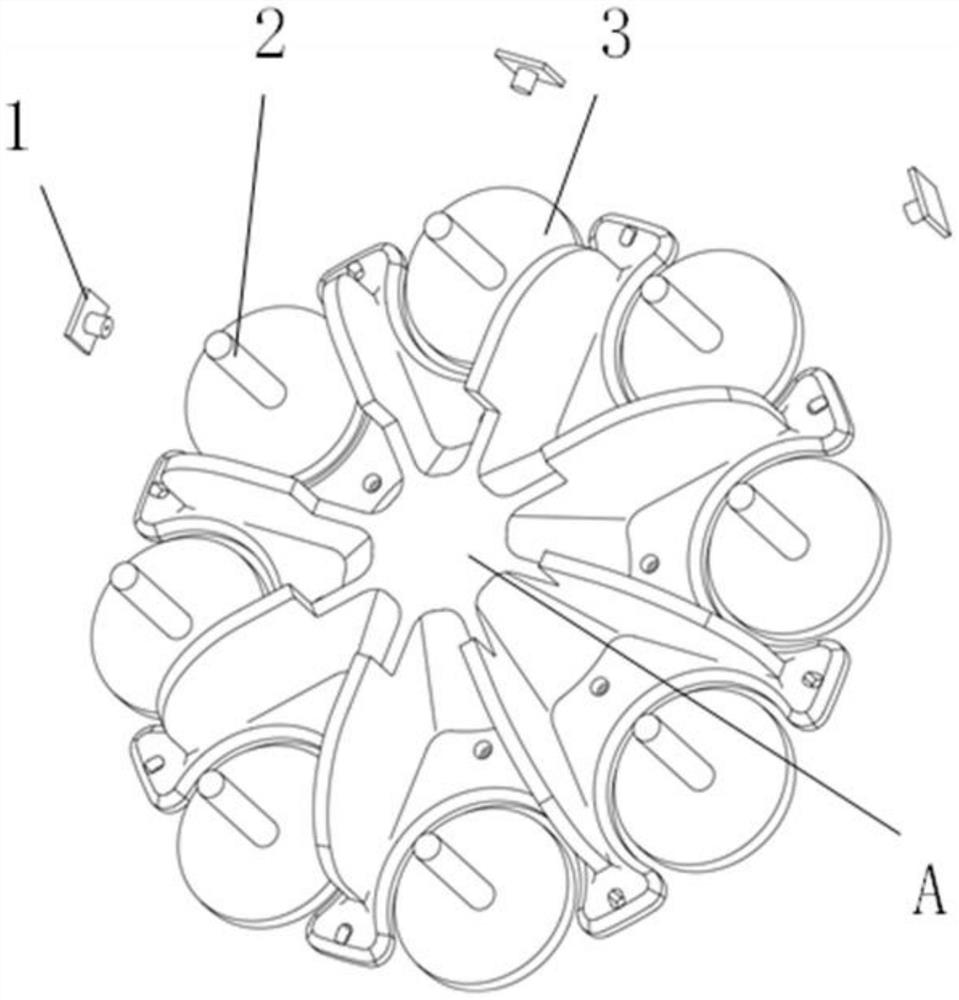

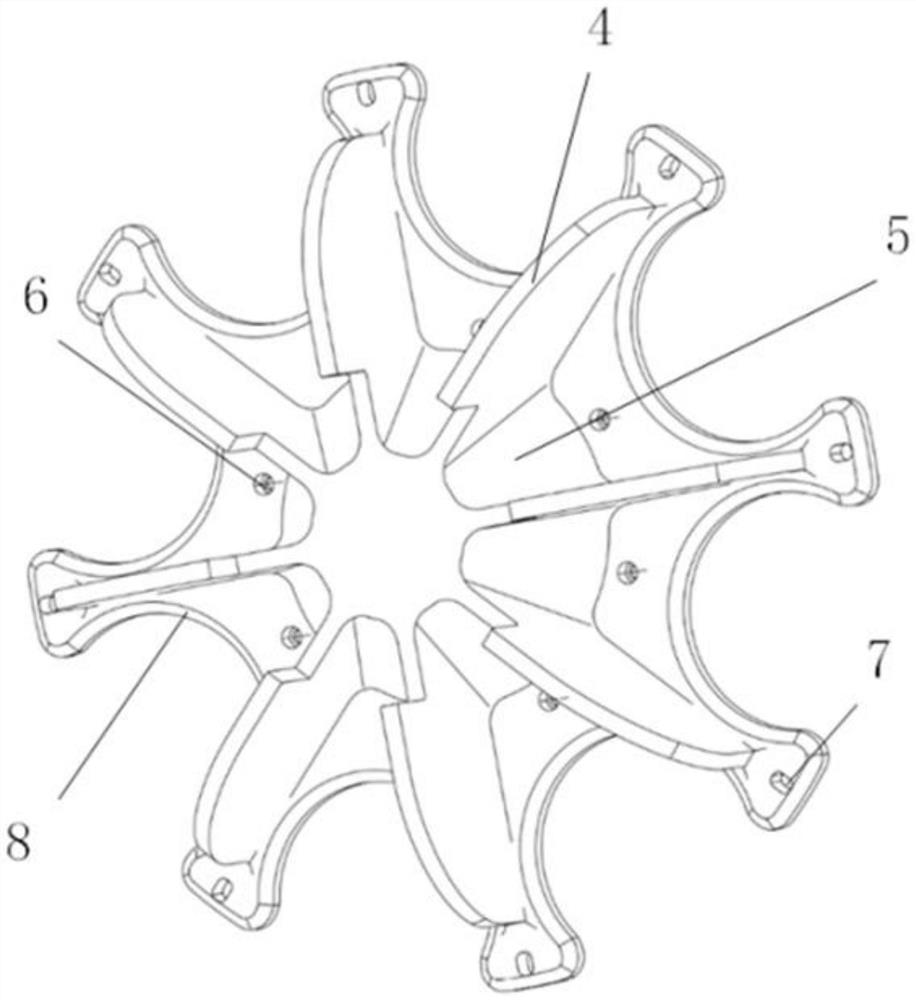

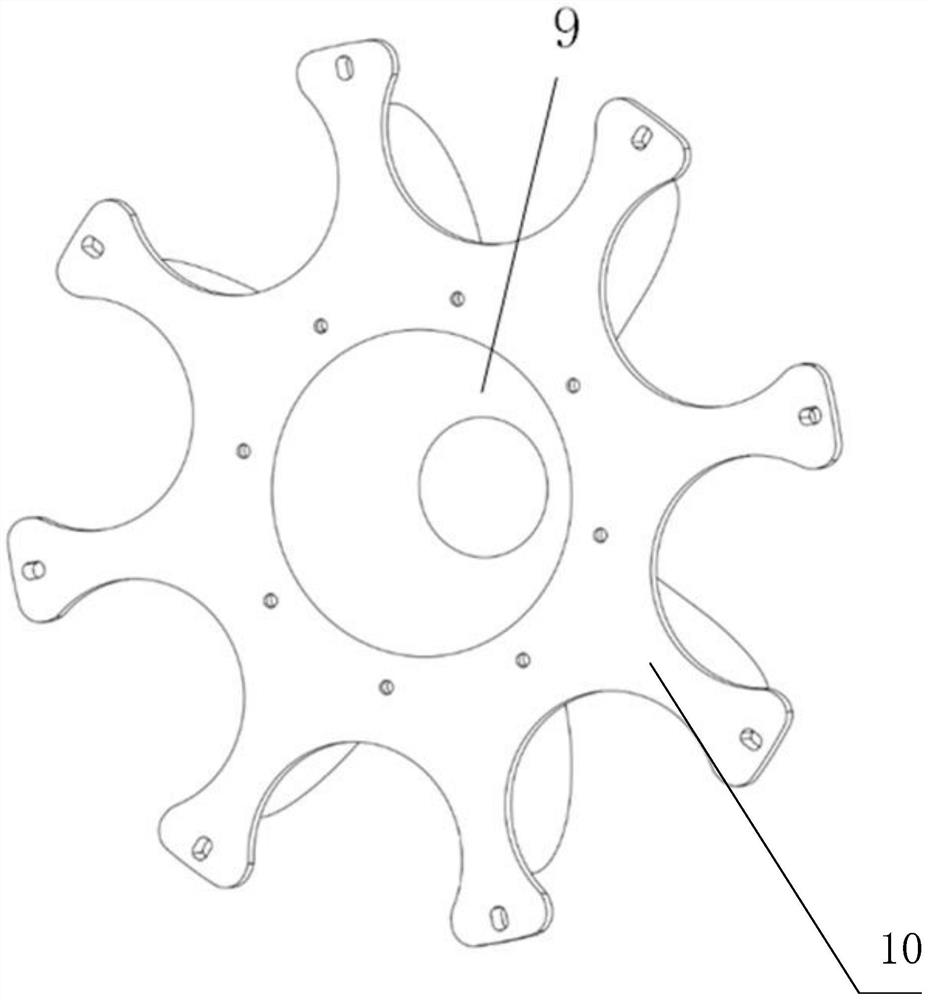

[0022] exist Figure 2 to Figure 3 In the schematic diagram of the present invention shown, the present invention consists of a number of frame structures distributed in an array along the circumference and a base plate 10. The base plate is provided with adjustment holes 7, which are connected and fixed with the machine tool by screws. The edge of the bottom plate has a chamfered design to facilitate the smooth discharge of chips. Several spacer frame mechanisms distributed along the circumference array are connected, and each spacer frame structure is a space fan-shaped area enclosed by the pyramid inclined surface 8 , the spacer plate 4 and the spacer frame bottom plate 5 . The pyramid inclined surface 8 is provided with a circular array of stepped screw through holes 6, which are connected and fixed with the machine tool by screws. There is a hollow 9 design inside the pyramid to reduce the mass of the device. The edges and corners of the separator are rounded to facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com