Preparation equipment and preparation method of sodium nitrate

A technology of sodium nitrate and equipment, which is applied to the preparation and molding of alkali metal nitrate, alkali metal nitrate, chemical instruments and methods, etc., can solve the problems of reducing crystallization output, increasing the fluctuation of the boiling surface of mother liquor, and increasing the downtime of the crystallizer. , to achieve the effect of reducing cleaning time, increasing working time and avoiding production reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

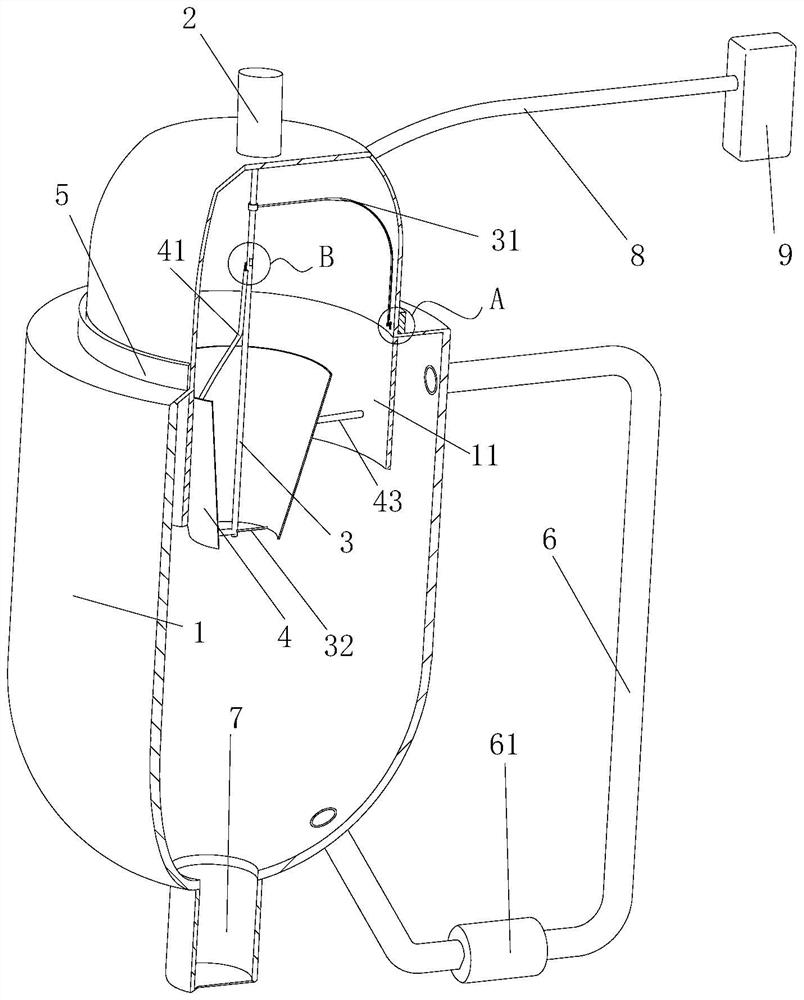

Method used

Image

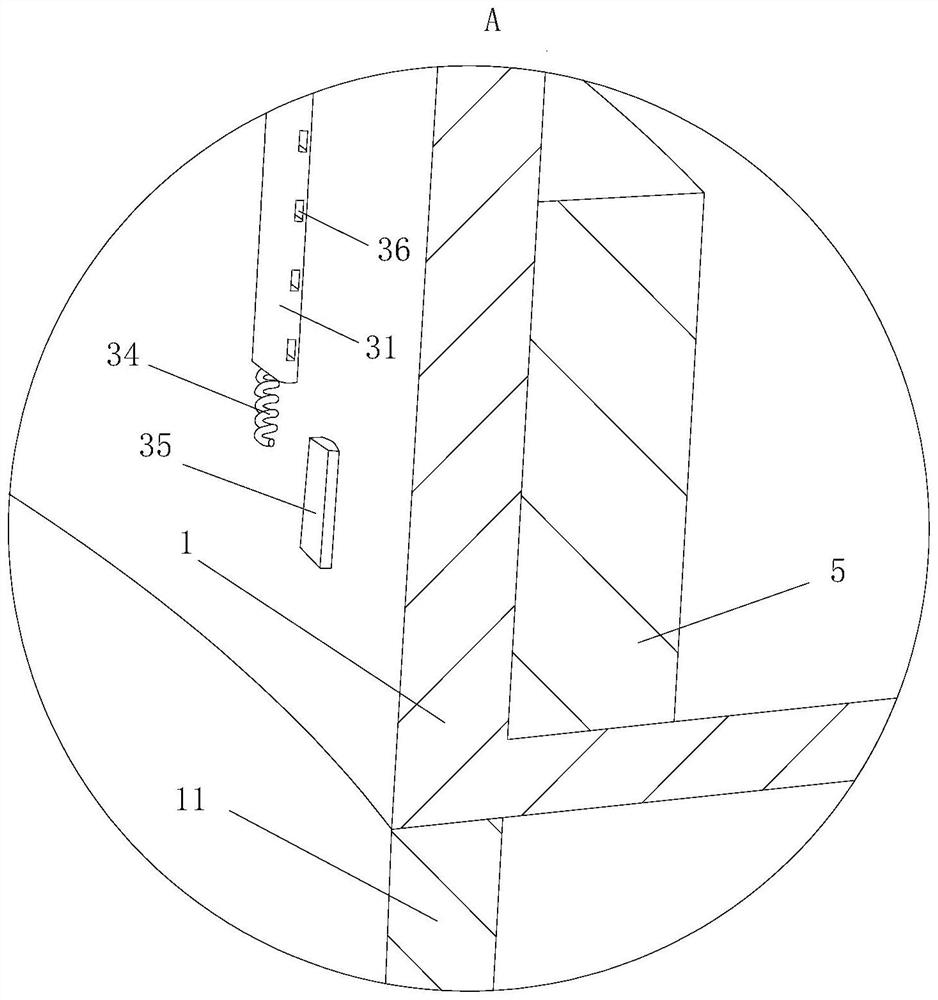

Examples

Embodiment approach

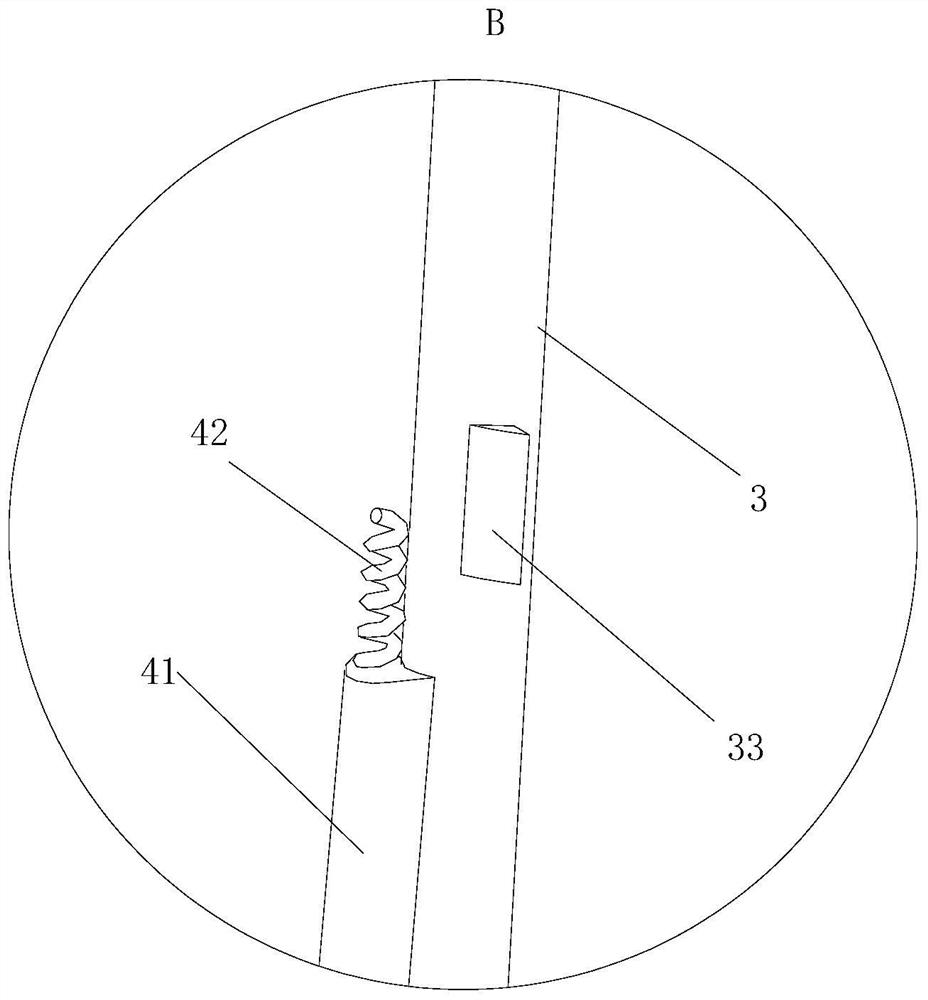

[0043] As an embodiment of the present invention, the second scraper 41 is close to the inner concave on one side of the stirring shaft 3 , and the radian of the inner concave is the same as the radian of the outer surface of the stirring shaft 3 .

[0044] During operation, in order to make the No. 2 scraper 41 close to the stirring shaft 3, the No. 2 scraper 41 will scrape off the crystallization scar at the position above the boiling liquid surface on the outer surface of the stirring shaft 3, and the No. 2 scraper 41 is set tightly. One side of the stirring shaft 3 is concave, and the concave radian is the same as the radian of the outer surface of the stirring shaft 3, so that the No. 1 scraper 41 scrapes off the crystallization scar at the position above the boiling liquid surface on the outer surface of the stirring shaft 3 , scrape off the crystal scars on the outer surface of the stirring shaft 3 as much as possible to reduce the number of crystal scars remaining after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com