Nest and fissure sealing agent and preparation method thereof

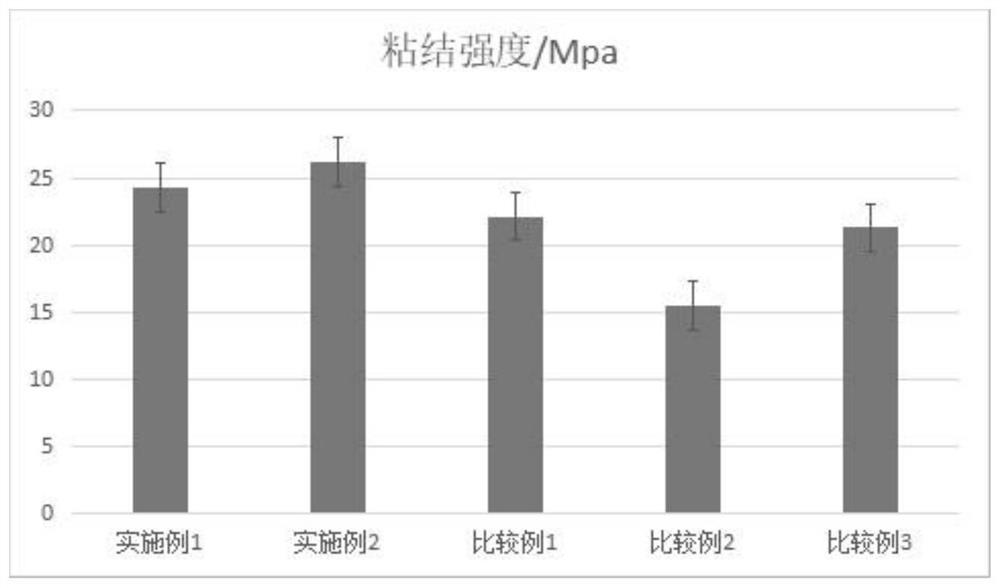

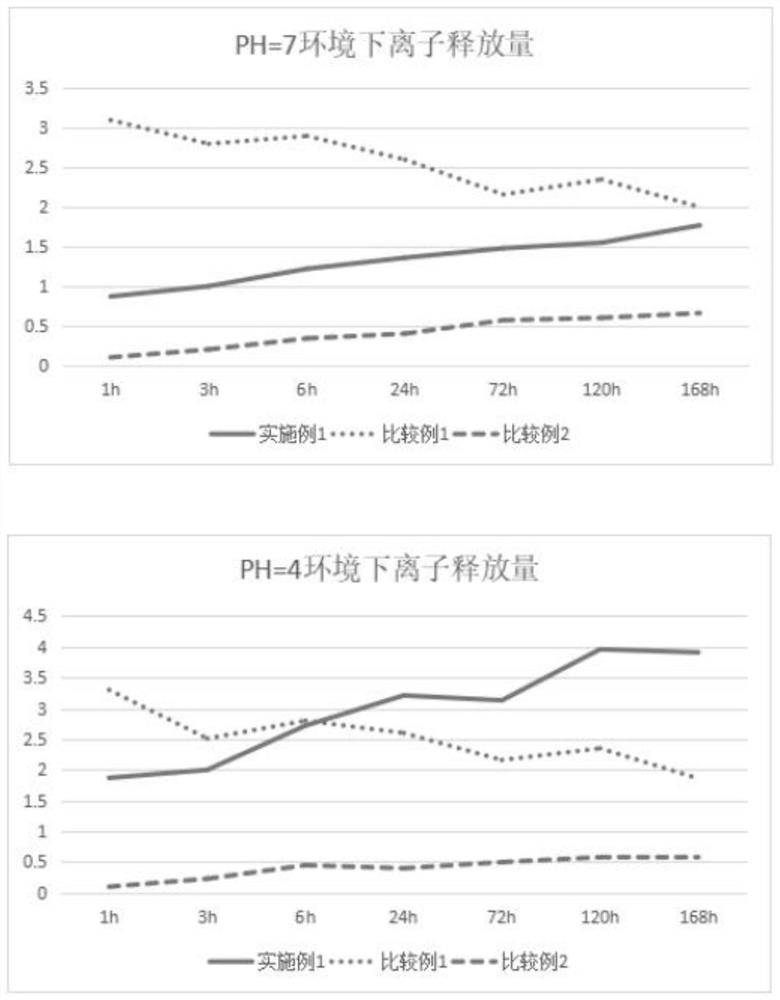

A pit and fissure sealing and diluent technology, which is used in pharmaceutical formulations, dental preparations, compression mold cups, etc., can solve the problems of inability to release effective substances for a long time, poor biocompatibility, and unadjustable degradation, and is not easy to deform or slip. , the effect of strong pH-responsive release, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A preparation method of pit and fissure sealant, comprising the following preparation steps:

[0057] (1) Weigh and add 35 parts of bisphenol A glycerol dimethacrylate, 40 parts of diluent (triethylene glycol dimethacrylate) and inorganic filler (fumed silica) in sequence in a stirring tank 5 parts, stirring at 500r / min for 30min to obtain the first material;

[0058] (2) 20 parts of modified bioactive glass and 2 parts of photoinitiator (diphenyliodonium hexafluorophosphate) were weighed in turn and added to the first material, stirred at 800r / min for 30min, and then irradiated with a light curing machine for 20s After curing, the sample of Example 1 was obtained.

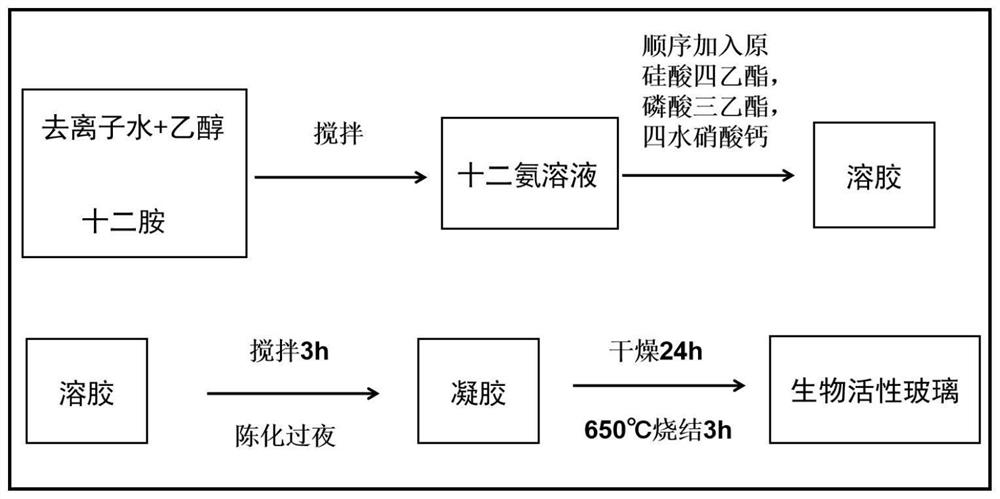

[0059] Wherein, the modified bioactive glass is prepared by the following method:

[0060] (1) Preparation of MBGS: MBGS (bioactive glass) was prepared by a modified sol-gel method by using DDA (dodecylamine) as a catalyst and template. The molar composition of MBGS is 80% SiO 2 , 16%CaO and 4%P 2 O 5...

Embodiment 2

[0068] A preparation method of pit and fissure sealant, comprising the following preparation steps:

[0069] (1) Weigh and add 40 parts of bisphenol A glycerol dimethacrylate, 35 parts of diluent (triethylene glycol dimethacrylate) and inorganic filler (fumed silica and Titanium dioxide is mixed in any proportion) 5 parts, and stirred at 600r / min for 45min to obtain the first material;

[0070] (2) 17 parts of modified bioactive glass and 2 parts of photoinitiator (camphorquinone) were weighed into the first material in turn, stirred at 900r / min for 45min, and then irradiated with a light curing machine for 20s to complete curing, that is, the embodiment was obtained. 2 samples.

[0071] Wherein, the modified bioactive glass is prepared by the following method:

[0072] (1) Preparation of MBGS: MBGS (bioactive glass) was prepared by a modified sol-gel method by using DDA (dodecylamine) as a catalyst and template. The molar composition of MBGS is 80% SiO 2 , 16%CaO and 4%P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com