Self-adaptive closed-loop feedback control system and method for silicon resonance pressure sensor

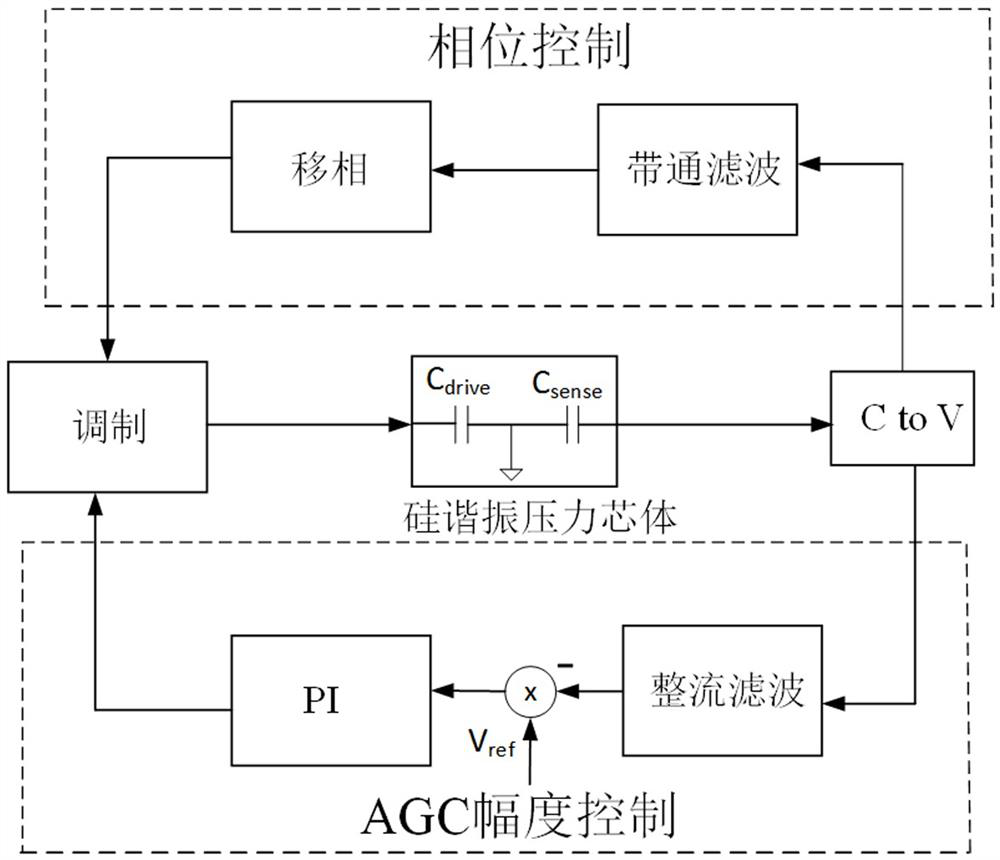

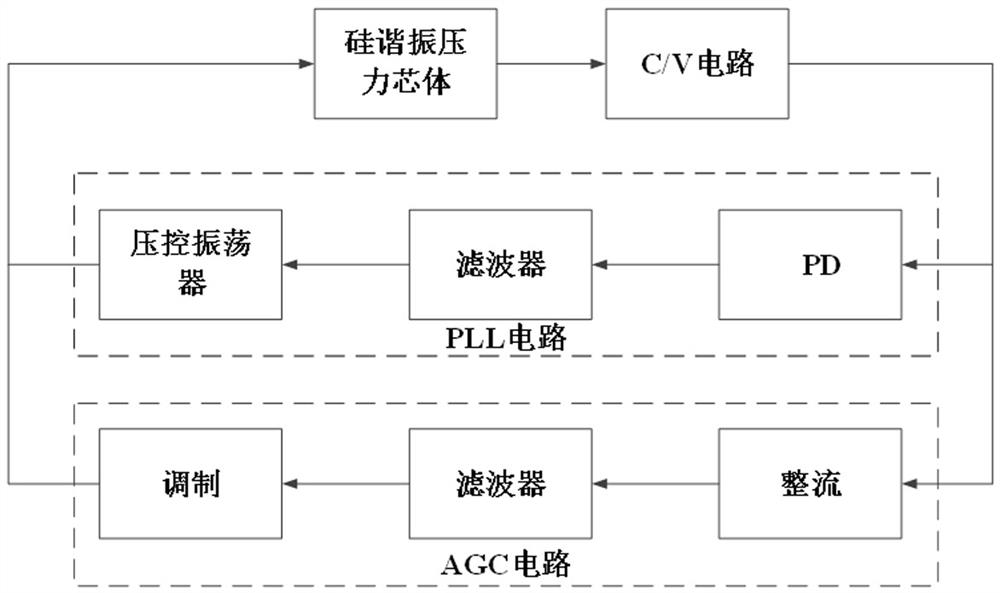

A pressure sensor and closed-loop feedback technology, which is applied in the direction of generator vibration, output stability, electrical components, etc., can solve problems such as difficult to separate analog devices, increase the start-up time of silicon resonant closed-loop circuits, and fail to meet phase difference conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

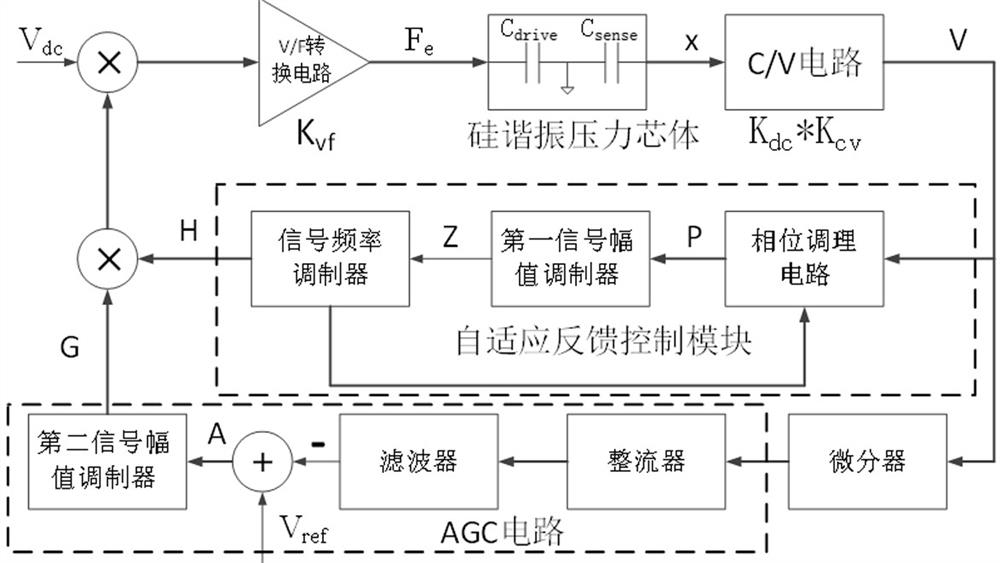

[0071] like image 3 As shown, the present invention provides an adaptive closed-loop feedback control system for a silicon resonant pressure sensor, comprising a V / F conversion circuit, a silicon resonant pressure core connected to the V / F conversion circuit, and a silicon resonant pressure core connected to the V / F conversion circuit. A C / V circuit connected to the resonant pressure core, an adaptive feedback control module and a differentiator connected to the C / V circuit respectively, and an AGC circuit connected to the differentiator, the AGC circuit and the adaptive feedback control module connection;

[0072] The V / F conversion circuit is used to convert electrical signals into electrostatic force F e , to drive the silicon resonant pressure core to generate harmonic vibration;

[0073] The silicon resonant pressure core for receiving electrostatic force F e Drive to form harmonic vibration, resulting in displacement change x;

[0074] The C / V circuit is used to con...

Embodiment 2

[0124] like Figure 4 As shown, the present invention provides an adaptive closed-loop feedback control method for a silicon resonant pressure sensor, and its implementation method is as follows:

[0125] S1. Convert electrical signals into electrostatic force F e , to drive the silicon resonant pressure core to generate harmonic vibration;

[0126] S2, the silicon resonance pressure core is subjected to electrostatic force F e Drive to generate displacement change x;

[0127] S3. Convert the displacement change x into a voltage signal V;

[0128] S4, using proportional-integral operation and adaptive loop feedback control respectively, the control voltage signal V and the high-frequency carrier signal H form a -90° phase difference;

[0129] S5, perform differential operation on the voltage signal V, and adjust the dynamic characteristics of the adaptive closed-loop feedback control system;

[0130] S6. According to the differential operation result, the amplitude of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com