Three-stage control system and method for wide-range bidirectional DCDC electronic load

An electronic load and three-level control technology, which is applied in control/regulation systems, high-efficiency power electronic conversion, electrical components, etc., can solve the problems of high test cost, difficult debugging, low test accuracy, etc., and achieve low test cost and high power The effect of density, simplicity of circuit topology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the advantages and features of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

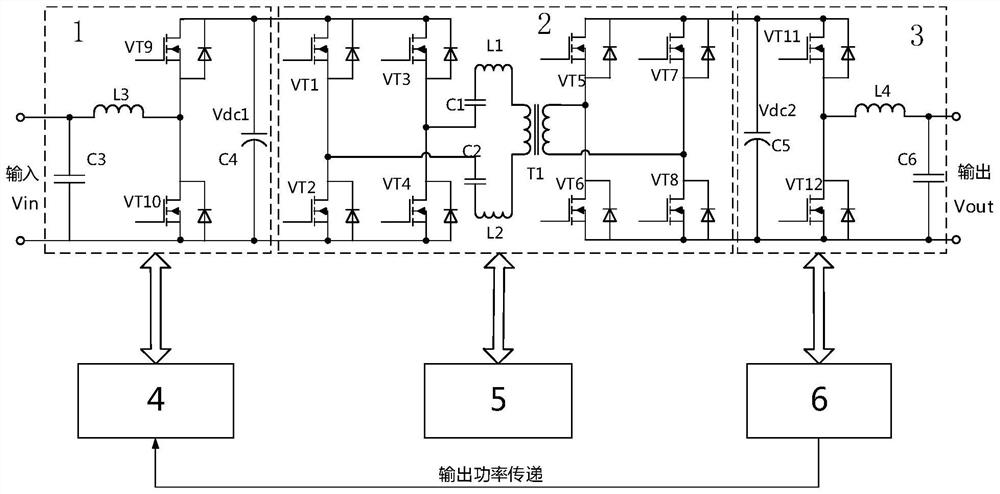

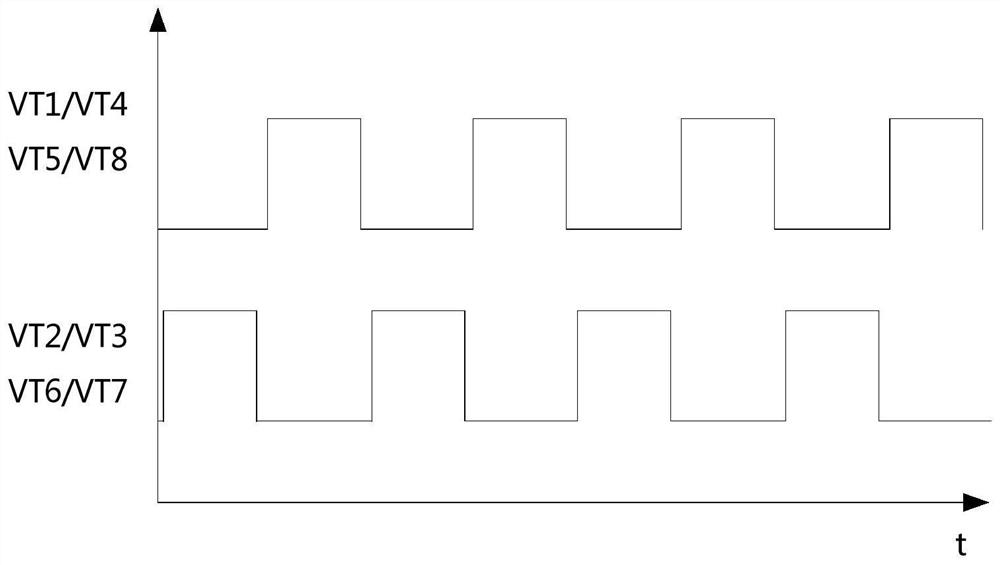

[0049] like figure 1 As shown, a three-stage control system for a wide-range bidirectional DCDC electronic load includes an input stage circuit 1, an intermediate stage circuit unit, an output stage circuit 3 connected in sequence, and a first control system 4 connected to the input stage circuit 1, A second control system 5 connected to the intermediate stage circuit unit and a third control system 6 connected to the output stage circuit 3 . At the same time, the feedback output end of the third control system 6 is connected to the input end of the first control system 4 for current feedforward to improve the response speed of the control system.

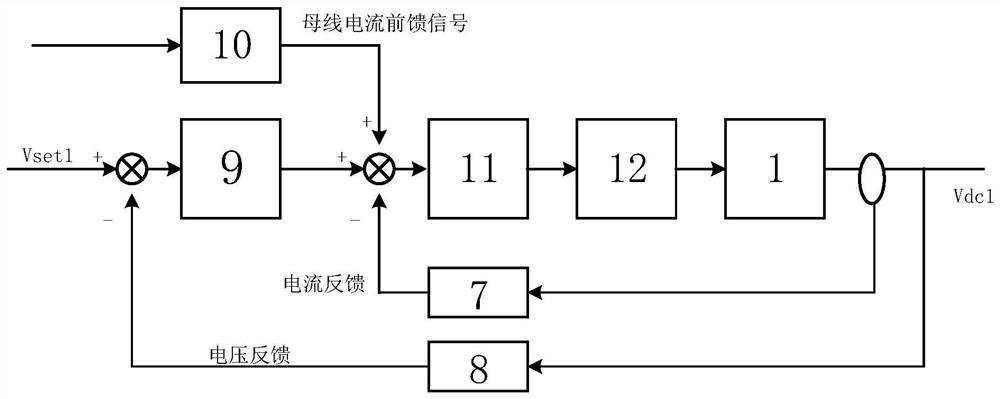

[0050] The input stage circuit 1 is a bidirectional buck-boost circuit, including a third capacitor C3, a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com