Method for preparing VS2 sodium-ion battery negative electrode material by one-step solvothermal method

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complexity, unsatisfactory initial Coulombic efficiency, and high cost, and achieve the effect of simple operation, favorable electron transfer, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: A Preparation of VS 2 Method for anode material of sodium ion battery

[0026] Specifically include the following steps:

[0027] (1) Measure 30 ml of nitrogen methyl pyrrolidone solution;

[0028] (2) Dissolve 0.468 g of vanadium source in NMP solution, stir for 30 min, add 1 g of thioacetamide, then add 4 mL of ammonia water, and continue to stir for 60 min.

[0029] (3) It was then transferred to a stainless steel reactor, kept at 180 °C for 20 h, and then lowered to room temperature. The obtained product was centrifuged, washed, and dried at 60 °C for 12 h to obtain VS 2 Solid powder, namely the VS 2 Anode material for sodium ion battery.

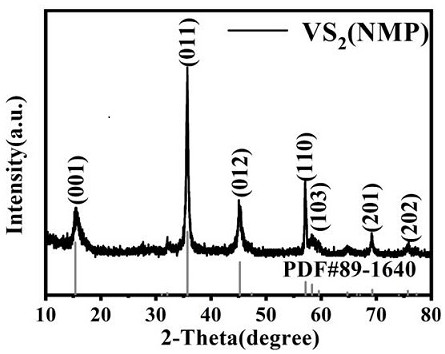

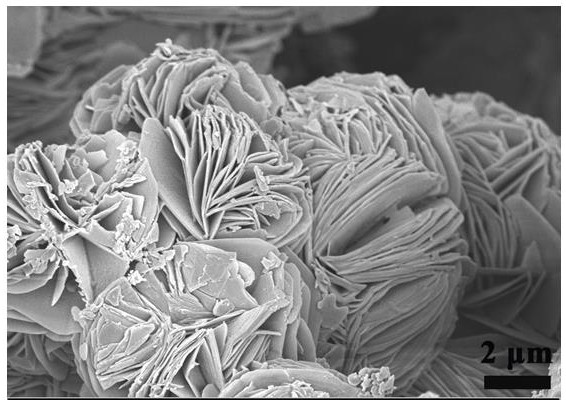

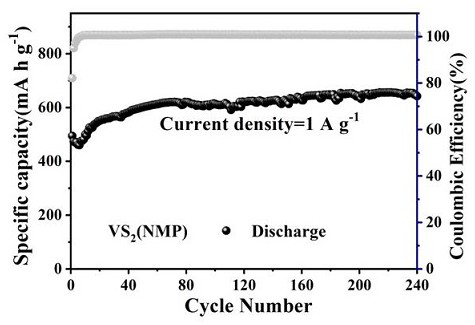

[0030] to the resulting VS 2 The anode material of sodium ion battery was tested, and its XRD pattern was as follows figure 1 shown, from figure 1 It can be seen in VS 2 (NMP) diffraction peaks all correspond to layered VS 2 (JCPDS No. 89-1640), its space group is P-3ml. It can be seen from the XRD pattern th...

Embodiment 2

[0032] Example 2: A Preparation of VS 2 Method for anode material of sodium ion battery

[0033] Specifically include the following steps:

[0034] (1) Measure 30 mL of nitrogen methyl pyrrolidone solution;

[0035] (2) Dissolve 0.468 g of vanadium source in NMP solution, stir for 40 min, add 1 g of thioacetamide, then add 6 mL of ammonia water, and continue to stir for 120 min.

[0036] (3) It was then transferred to a stainless steel reactor, kept at 160 °C for 20 h, and then lowered to room temperature. The obtained product was centrifuged, washed, and dried at 60 °C for 12 h to obtain VS 2 solid powder.

Embodiment 3

[0037] Example 3: A Preparation of VS 2 Method for anode material of sodium ion battery

[0038] Specifically include the following steps:

[0039] (1) Measure 30 mL of nitrogen methyl pyrrolidone solution;

[0040] (2) Dissolve 0.468 g of vanadium source in NMP solution, stir for 50 min, add 1 g of thioacetamide, then add 5 mL of ammonia water, and continue to stir for 100 min.

[0041](3) It was then transferred to a stainless steel reactor, kept at 180 °C for 22 h, and then lowered to room temperature. The obtained product was centrifuged, washed, and dried at 60 °C for 12 h to obtain VS 2 solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com